Blacksmithing yog ib txoj kev siv hlau qub qub thiab tseem ceeb uas muaj hnub rov qab mus rau xyoo 2000 BC.Nws ua hauj lwm los ntawm cua sov ib tug hlau dawb paug mus rau ib tug tej yam kub thiab ces siv lub siab los ua nws nyob rau hauv lub siab xav.Nws yog ib txoj hauv kev rau kev tsim cov khoom muaj zog, siab ua haujlwm ntev.Hauv cov txheej txheem forging, muaj ob txoj hauv kev, uas yog dawb forging thiab tuag forging.Kab lus no yuav tshawb txog qhov sib txawv, qhov zoo thiab qhov tsis zoo, thiab kev siv ntawm ob txoj hauv kev no.

Dawb Forging

Dawb forging, tseem hu ua dawb rauj forging lossis cov txheej txheem forging dawb, yog ib txoj kev ntawm hlau forging yam tsis muaj pwm.Nyob rau hauv cov txheej txheem forging dawb, lub forging dawb paug (feem ntau yog ib qho hlau thaiv los yog pas nrig) yog rhuab mus rau qhov kub uas nws dhau los ua yas txaus thiab tom qab ntawd ua rau cov duab xav tau siv cov cuab yeej xws li forging rauj lossis forging xovxwm.Cov txheej txheem no yog nyob ntawm kev txawj ntawm cov neeg ua haujlwm khiav haujlwm, uas yuav tsum tau tswj cov duab thiab qhov loj me los ntawm kev soj ntsuam thiab paub txog cov txheej txheem forging.

Qhov zoo ntawm free forging:

1. Flexibility: Dawb forging yog tsim rau workpieces ntawm ntau yam duab thiab ntau thiab tsawg vim hais tias tsis muaj yuav tsum tau ua complex pwm.

2. Cov khoom txuag: Vim tsis muaj pwm, tsis muaj cov khoom siv ntxiv los ua pwm, uas tuaj yeem txo cov khoom pov tseg.

3. Haum rau me me batch ntau lawm: Dawb forging yog tsim rau me me batch ntau lawm vim hais tias loj zus tau tej cov pwm yog tsis yuav tsum tau.

Disadvantages ntawm free forging:

1. Kev cia siab rau cov neeg ua haujlwm cov txuj ci: Qhov zoo ntawm kev forging yog nyob ntawm cov neeg ua haujlwm kev txawj ntse thiab kev paub dhau los, yog li cov kev xav tau ntawm cov neeg ua haujlwm siab dua.

2. Slow ntau lawm ceev: Piv nrog tuag forging, qhov ntau lawm ceev ntawm dawb forging yog qeeb.

3. Kev tswj qhov zoo thiab qhov loj me yog qhov nyuaj: Yog tias tsis muaj kev pab cuam ntawm pwm, cov duab thiab qhov loj me ntawm kev tswj cov forging yog qhov nyuaj thiab yuav tsum tau ua ntau dua.

Free forging daim ntawv thov:

Free forging yog muaj nyob rau hauv cov nram qab no:

1. Kev tsim ntau yam hlau qhov chaw xws li forgings, rauj qhov chaw, thiab castings.

2. Ua kom muaj zog thiab ua haujlwm siab ua haujlwm zoo xws li crankshafts, txuas rods, thiab bearings.

3. Casting cov khoom tseem ceeb ntawm cov tshuab hnyav thiab cov khoom siv engineering.

Tuag Forging

Tuag forging yog txheej txheem uas siv cov tuag forging hlau.Nyob rau hauv cov txheej txheem no, ib tug hlau dawb paug yog muab tso rau hauv ib tug tshwj xeeb tsim pwm thiab ces shaped mus rau hauv lub siab xav los ntawm lub siab.Pwm tuaj yeem yog ib qho lossis ntau qhov, nyob ntawm qhov nyuaj ntawm qhov.

Qhov zoo ntawm kev tuag forging:

1. High precision: Tuag forging tuaj yeem muab cov duab zoo meej thiab tswj qhov loj me, txo qhov xav tau rau kev ua haujlwm tom ntej.

2. Cov zis siab: Txij li cov pwm tuaj yeem siv ntau zaus, pwm forging yog tsim rau kev tsim khoom loj thiab txhim kho kev tsim khoom.

3. Zoo sib xws: Tuag forging tuaj yeem ua kom muaj qhov sib xws ntawm txhua qhov thiab txo qhov sib txawv.

Disadvantages ntawm tuag forging:

1. Cov nqi tsim khoom siab: Tus nqi ntawm kev ua cov pwm ua haujlwm yog qhov siab, tshwj xeeb tshaj yog rau cov khoom me me, uas tsis raug nqi.

2. Tsis haum rau cov duab tshwj xeeb: Rau qhov nyuaj heev lossis tsis zoo li tus qauv, yuav tsum tau ua cov pwm kev cai kim.

3. Tsis haum rau qhov kub thiab txias forging: Tuag forging feem ntau yuav tsum tau kub dua thiab tsis haum rau qhov chaw uas yuav tsum tau kub forging.

Daim ntawv thov ntawm tuag forging:

Tuag forging yog dav siv hauv cov nram qab no:

1. Kev tsim cov khoom siv tsheb xws li cav crankshafts, nres discs, thiab log hubs.

2. Kev tsim cov khoom tseem ceeb rau kev lag luam aerospace, xws li cov dav hlau fuselages, cav qhov chaw, thiab cov khoom tswj kev ya davhlau.

3. Tsim cov khoom siv high-precision engineering xws li bearings, gears thiab racks.

Feem ntau, pub dawb forging thiab tuag forging txhua tus muaj lawv tus kheej qhov zoo thiab kev txwv thiab tsim nyog rau kev xav tau ntau lawm.Xaiv txoj kev forging tsim nyog nyob ntawm qhov nyuaj ntawm qhov, qhov ntim ntau lawm, thiab qhov yuav tsum tau muaj tseeb.Hauv kev siv tswv yim, cov xwm txheej no feem ntau yuav tsum tau ntsuas los txiav txim siab qhov zoo tshaj plaws forging txheej txheem.Kev txhim kho txuas ntxiv thiab txhim kho cov txheej txheem forging yuav txuas ntxiv mus rau kev tsav tsheb ntawm ob txoj hauv kev.

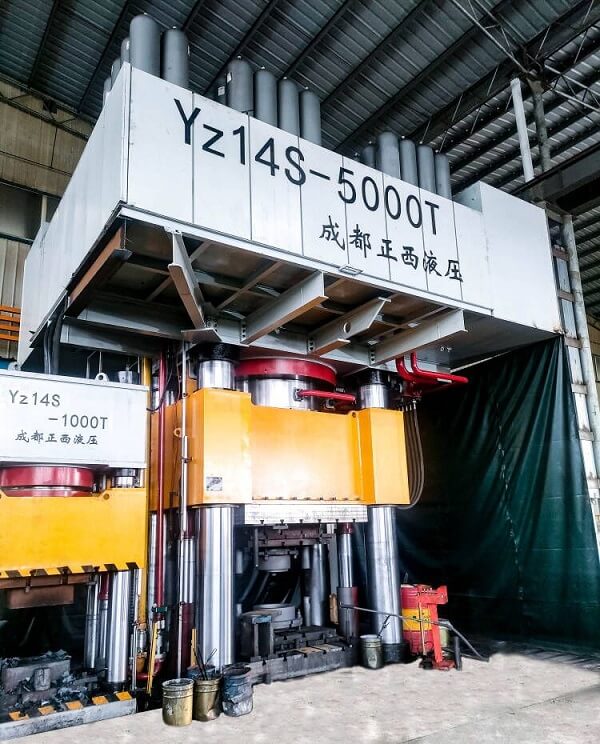

Zhengxi yog tus kws tshaj lijforging xovxwm Hoobkas nyob rau hauv Suav teb, muab high-zoo dawbforging pressesthiab tuag forging presses.Tsis tas li ntawd, hydraulic presses kuj tuaj yeem kho thiab ua raws li cov neeg siv khoom xav tau.Yog tias koj muaj kev xav tau, thov hu rau peb.

Post lub sij hawm: Sep-09-2023