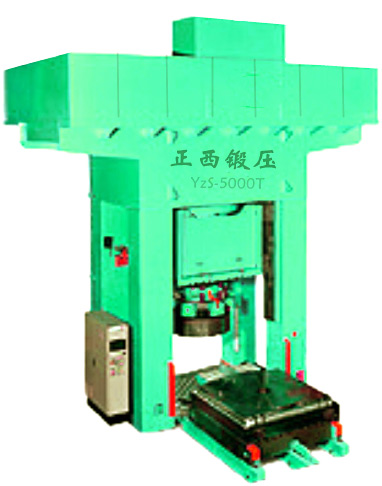

Hot Forging Hydraulic Press

Yz14 Ngwa ngwa nrụnye hydraulic n'efu

Ụdị etiti na nhazi akụkụ anọ;

Iji usoro nchịkwa servo, nchekwa ike dị elu;

Ngwa ngwa 400 ~ 1000mm / S, na-akpụ 50 ~ 200mm / S;

A na-eji ihe Q355B welded ahụ, yana nkwụsi ike zuru oke;

Ejiri ihe mkpuchi elu yana ihe nchekwa nchekwa nkwado abụọ;

Nhọrọ inyeaka centering ngwaọrụ, inyeaka ọkpọ ọkpọ, nkenke akpaka forging, manipulator na ndị ọzọ nhazi;

Free forging, kwesịrị ekwesị maka nnukwu forgings nwere ọdịdị dị mfe, maka ịmepụta nnukwu osisi dị iche iche, mgbanaka, achịcha, ingots na efere;

Kwesịrị ekwesị maka ịgha ụdị carbon dị iche iche, ígwè alloy, ngwá ọrụ ígwè, ígwè na-ebu ígwè, mmiri ígwè, igwe anaghị agba nchara na elu okpomọkụ alloy ígwè;

Ejiri ya na mbara igwe, ike, ụlọ ọrụ, iwu ụgbọ mmiri, njem na mpaghara ndị ọzọ;

Precision Die Forging Hydraulic Press

Ụdị etiti na ihe owuwu nke kọlụm anọ, nke enwere ike iji maka ịdị ọkụ na-ekpo ọkụ ma ọ bụ extrusion oyi.

Sistemụ njikwa ọrụ Servo, ịkpụzi obere mmegharị, nrụgide na njikwa ọnọdụ 1%;

Na-agbanwe agbanwe ọsọ 1 ~ 100mm / S, stepless ọsọ mgbanwe, elu akpụ ziri ezi;

A na-eji ihe Q355B welded ahụ, yana nkwụsi ike zuru oke;

Ejiri cylinders ejection elu na nke dị ala, ejection cylinder nwere ihe mmetụta arụnyere na-achịkwa nke ọma na-akpụzi ihe;

A na-eji ya eme ihe na ụgbọ ala, igwe, petrochemical, nrụpụta ọkụ ọkụ, ikuku ikuku, ụgbọ mmiri na ụlọ ọrụ ndị ọzọ.

Ịkpụzi otu oge nke akụkụ nhazi polyhedral nwere ike ịbawanye ike nke akụkụ ahụ nke ọma, belata ọnụ ahịa mmepụta, ma kwalite akụkụ ndị dị ọkụ.

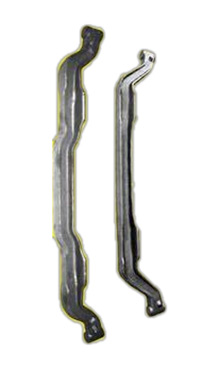

Hot Die Forging Hydraulic Press

Akụkụ bụ isi nke ịnwụ anwụ na-ekpo ọkụ bụ njikwa okpomọkụ dị n'etiti ebu na akụkụ ahụ kpụrụ.Enwere ike ịtọ ọnọdụ okpomọkụ ka ọ dị elu karịa okpomọkụ ihe onwunwe, isothermal, na obere okpomọkụ. Ihe ndị na-eme ka ọkpụkpụ na-emekarị recrystallization dị ike n'oge usoro nhazi, nke na-eme ka ihe owuwu ahụ dị n'otu na equiaxed fine crystal morphology;

Izi ezi njikwa nrụgide ± 0.1Mpa, izi ezi njikwa ọnọdụ ± 0.02mm.

The akpụ ọsọ bụ ngwa ngwa, kpụrụ akụkụ nwere elu akụkụ ziri ezi na ọnụ ala ..

Nhọrọ ọkụ ọkụ eletrik, oge etiti, ugboro ugboro na ụzọ ndị ọzọ na-ekpo ọkụ, nkwụnye akpaka na nbudata, na-apụ na bench ọrụ;

A na-eji ya eme njem, ụgbọ ala, ikuku, ụgbọ mmiri, akụrụngwa, elektrọnik 3C na mpaghara ndị ọzọ.

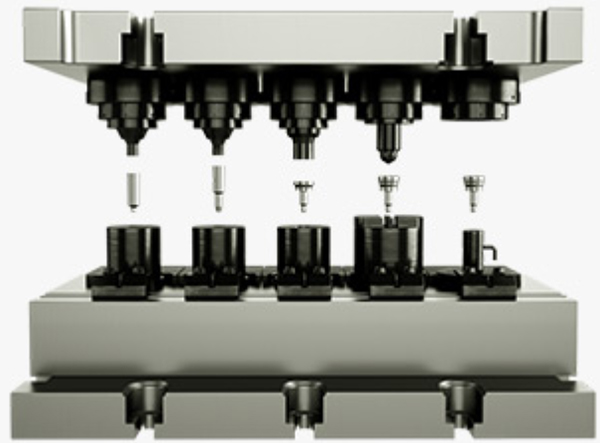

Multi-usoro Die Forging Hydraulic Press

Multi-usoro anwụ forging hydraulic pịa bụ multi-ọdụ synchronous forging akụrụngwa, adabara akpụ pụrụ iche forgings, na nwekwara ike-eji maka otu usoro-akpụ na oyi extrusion Filiks;

Sistemụ njikwa ọrụ Servo, njikwa akụ kwụsiri ike, nchekwa ike dị elu;

Okpokoro ụdị fuselage ndu Ọdịdị, ngwa ngwa forging 2 ~ 5 Filiks, 3 ~ 30s / oge forging ọsọ, elu forging ziri ezi;

Q355B ihe welded ahụ, ike n'ozuzu rigidity;

1 ~ 80MN ahaziri ahaziri, ngwaọrụ n'akpaaka akpaka nhọrọ, ntinye akpaka na ebutu robot, robot nzọụkwụ na nhazi ndị ọzọ.

Ọdabara dị iche iche forging ngwaahịa na mfe na symmetrical shapes;

Obere ogwe, mgbanaka, achicha, ingot, efere, aka uwe, nhazi nhazi;

Forging nke dị iche iche carbon ígwè, alloy ígwè, ngwá ọrụ ígwè, na-ebu ígwè, mmiri ígwè, igwe anaghị agba nchara na elu okpomọkụ alloy ígwè;

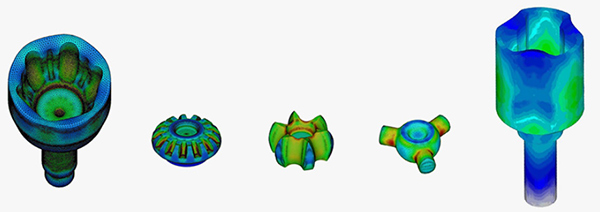

Multi-directional Die Forging Hydraulic Press

A na-emepụta usoro a nke hydraulic presses na usoro etiti, nke nwere isi mmanụ mmanụ na ihu, azụ, aka ekpe na aka nri, nke nwere ike siri ike na nkenke dị elu;

Ihe owuwu ahụ dị mfe, ọnụọgụ ihe eji eme ihe dị elu, a na-emepụta ọtụtụ forgings n'otu oge, na ọnụ ahịa mmepụta na-ebelata;

Speed 50 ~ 400mm / S, synchronous extrusion na akụkụ cylinder : The ahu na-welded na Q355B ihe, na ike n'ozuzu rigidity;

Isi akpụ ngwaahịa nwere nnukwu nkenke na ọ dịghị forging anwụ taper ; Iji servo akara usoro, elu ike ịzọpụta;

Tinyere na ngwaahịa dị iche iche nwere ụdị mgbagwoju anya na ọnụ ọgụgụ buru ibu;

Kwesịrị ekwesị maka akụkụ valvụ dị iche iche, nkwonkwo ọkpọkọ, nkwonkwo njedebe, mgbakọ diski diski na ihe ndị ọzọ na-emepụta ihe;

Kwesịrị ekwesị maka imepụta ihe dị iche iche carbon ígwè, ọla kọpa, aluminom na alloy ígwè;

Enwere ike ịhazi ya ozugbo site na iji manipulator na-ekpo ọkụ na-ekpo ọkụ na ọkụ etiti oge iji ghọta ịkpụzi akpaaka zuru oke;