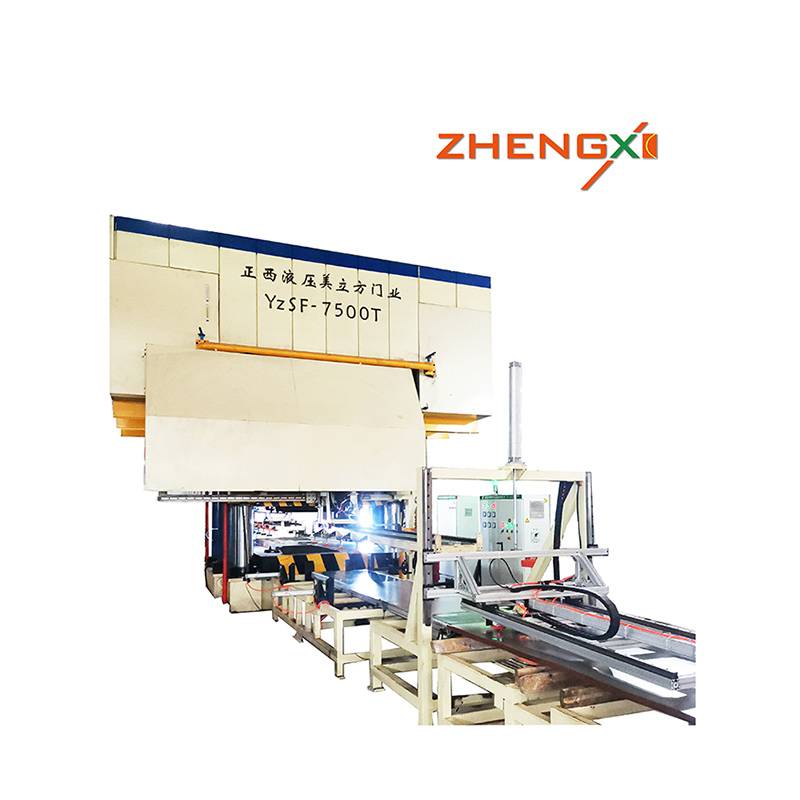

High Quality for Powder Metal Hydraulic Press - 60T Powder Metallurgy Forming Hydraulic Press Machine – Zhengxi

High Quality for Powder Metal Hydraulic Press - 60T Powder Metallurgy Forming Hydraulic Press Machine – Zhengxi Detail:

The powder metallurgy molding machine is mainly suitable for the production of powder metallurgy and mechanical parts based on structural parts. It is also suitable for the pressing of precision ceramics, electronic ceramics and cemented carbide products. This series of presses have independent hydraulic and electrical systems. With automatic feeding and reclaiming device, floating pressing, the product forming density can be effectively controlled, protective demolding and general demolding are available for selection, the electrical control adopts PLC controller, and the hydraulic system adopts advanced plug-in. The integrated valve ensures continuous, frequent and stable operation of the hydraulic press.

The mold base technology field in the powder metallurgy molding machine is designed and developed for processing multi-step, complex and high-precision powder metallurgy parts. Including the composite upper punching plate combination mechanism, the upper guide column combination mechanism, the female template combination mechanism, and the oblique sliding slide mechanism. The upper guide column combination mechanism is respectively connected to the composite upper punching plate combination mechanism and the female template combination mechanism, and the female template combination An oblique sliding slide mechanism is installed between the mechanism and the basic template. The composite upper punch board combination mechanism adopts a double upper punch mechanism, which is characterized by another lower guide column combination mechanism, which uses a lower guide column to connect to the female template combination mechanism and Between the lower template combination mechanisms, the basic template is sleeved on the lower guide column. It has the advantages of being suitable for automated production, improving production efficiency, reducing production costs, and the structure of the mold base is relatively simple and easy to implement. It is suitable for popularization and use in the powder metallurgy industry.

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for High Quality for Powder Metal Hydraulic Press - 60T Powder Metallurgy Forming Hydraulic Press Machine – Zhengxi , The product will supply to all over the world, such as: Uruguay, Oslo, Sweden, Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.