-

315T Hydraulic Press for Compressing PE Bulletproof Helmets

315-ton hydraulic press for compressing bulletproof helmets is specially designed for producing PE/Kevlar/Aramid fiber bulletproof helmets. It uses high-pressure processing technology to ensure the helmet material has sufficient protective properties. This helmet press can produce high-quality bulletproof helmets to ensure the safety of equipped troops. -

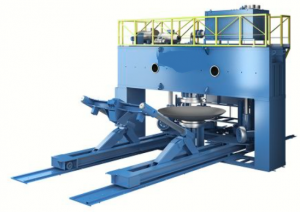

Dish end press machine

Zhengxi's dish end press has the characteristics of high production efficiency and good molding effect. It is mainly used for cold-pressed heads of various tank trucks, and can also be used for medium and thin plate forming, stretching, correction, and other processes within the parameter range. -

1600T Fast Forging Press

This machine is a 1,600-ton four-column forging hydraulic press, mainly used for rapid hot forging and forming processes of metal products. The fast forging press can be used for rapid hot forging of gears, shafts, round steel, square steel, bars, automobile forgings, and other products. The fuselage structure, opening, stroke, and work surface can be designed and customized according to the application requirements. -

4000T Truck Chassis Hydraulic Press

The 4000-ton truck chassis hydraulic press is used to stamp and form large plates such as automobile beams, floors, and beams. It can also be used to form bridge corrugated plates and corrugated plates. -

U-shaped Drainage Ditch Forming Hydraulic Press

The U-shaped drainage ditch forming hydraulic press machine usually has a high-precision control system that can ensure that the shape and size of the U-shaped gutters meet the specifications. Hydraulic presses play an important role in construction and urban infrastructure projects, helping to ensure the effectiveness and sustainability of drainage systems. -

500T Hydraulic Trimming Press for Car Interior

Our 500 tons hydraulic trim presses are used by many of the world’s leading manufacturers of automotive interior trim parts to produce an extensive assortment of innovative interior components. -

Mechanical Forging Presses

Zhengxi's mechanical forging presses are used to manufacture gear blanks, bearing races, wheel hubs, and other critical forgings for the automotive market.

High production flexibility, fast response time, and high standard part production efficiency.

Equipped with various accessories required for deep vertical and horizontal extrusion forging.

Profibus technology using full digital equipment, CNC programming, and electronically controlled automatic loading, and unloading.

Can work in continuous or discontinuous cycles, depending on requirements. -

Yz41-25T C-frame Hydraulic Press Machine

Our single-column hydraulic press adopts the C-shaped structure, which has a wide range of versatility. It is suitable for the pressing of plastic materials and powder products; the correction of shafts and other similar parts; the pressing of electrical parts; the stretching and forming of small plate-shaped parts Process uses such as blanking, creasing, and embossing. -

Cold forging hydraulic press

5000T cold forging hydraulic press, mainly be used for induction bottom pot, non-stick pot. Under pressure, press two metals together. The double-bottomed pot contacts the heat source layer and transfers heat quickly, which can make the heat and temperature distribution uniform. The layer inside the pot is smooth, wear-resistant, not easy to rust, and will not produce compounds harmful to human health. -

60T Powder Metallurgy Forming Hydraulic Press Machine

High-performance full-automatic powder hydraulic press and mold base, using advanced mechanical, electrical, hydraulic, and pneumatic integrated control, drive technology, special machines for powder metallurgy, ceramics, cemented carbide, magnetic materials, electrical contacts and neighboring industries. type.

Whatsapp: +86 151 028 06197 -

Four-column Deep Drawing Hydralic Press with Moving Worktable

The 4 column deep drawing press machine is mainly suitable for sheet metal part processes such as stretching, bending, crimping, forming, blanking, punching, correction, etc., and is mainly used for quick stretching and forming of sheet metal.

Whatsapp: +86 151 028 06197 -

Composite SMC BMC hydraulic press

Our hydraulic press machine are suitable for composite material moulding:

SMC (Sheet Moulding Compound) components

BMC (Bulk Moulding Compound) components

RTM (Resin Transfer Moulding) components

Different systems are used, depending on the component requirements and the production process. The result: Best parts quality and maximum production reliability – for greater economic efficiency and maximum productivity.

Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

+86 17781480014

-

Top