Composite hydraulic presses play a very important role in forming carbon fiber products. Carbon fiber consists of carbon fiber bundles (filament or chopped strands) and a resin matrix. In order for the carbon fibers to better bond with the resin and form the desired shape, a pressing and curing process is required, which requires the use of a composite press.

Table of Content:

1. Introduction of Carbon Fiber

2. Introduction of Composite Material Press

3. The Role of Composite Hydraulic Presses in Carbon Fiber Forming

4. Advantages of Using a Composite Press to Form Carbon Fiber Products

5. Future Prospects and Conclusions

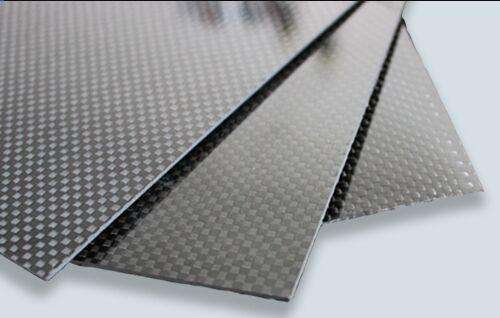

Introduction of Carbon Fiber

Carbon fiber is a light, high-strength, high-rigidity material composed of bundles of carbon atoms. Its superior performance makes it widely used in aerospace, automobile, sports equipment, and other fields. Carbon fibers are favored for their excellent mechanical properties such as low density, high tensile strength, and excellent chemical stability.

Introduction of Composite Material Press

The composite material press is a kind of mechanical equipment specially used to form composite material products. It combines the functions of high pressure and high temperature, which can combine different materials into the desired shape and ensure their stability during the curing process. The core components of a composite material press usually include a pressure system, a heating system, a control system, and a mold.

The Role of Composite Hydraulic Presses in Carbon Fiber Forming

1. Compression Molding: Composites presses apply high pressure and temperature to create uniform contact between carbon fiber and resin, compressing the material into the desired shape, and ensuring the final product has the desired strength and shape.

2. Curing the resin: During the pressing process, while applying heat, the resin cures and bonds firmly with the carbon fibers. This ensures the stability and durability of the final product.

3. Control process parameters: The composite material press can precisely control process parameters such as temperature, pressure, and time. The adjustment of these parameters can optimize the performance of the product according to different carbon fiber and resin combinations, as well as the desired molding shape.

4. Mass production: Composite hydraulic presses are suitable for mass production, and can quickly and stably manufacture a large number of carbon fiber products of the same specification. This is of great significance for industrial production.

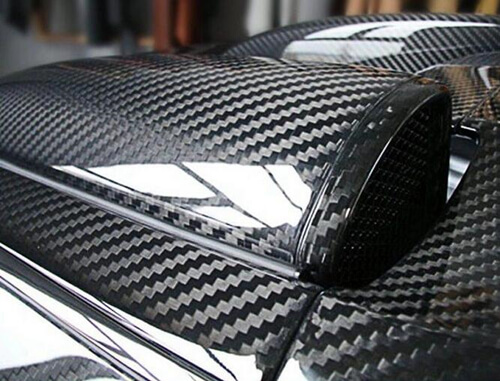

5. Improve material performance: Through the processing of composite material presses, the combination of carbon fiber and resin is tighter, which helps to improve the strength, rigidity, and durability of the product. This makes carbon fiber products widely used in aerospace, automobiles, sports equipment, and other fields.

In general, the composite material press plays a vital role in the forming process of carbon fiber products. It can combine carbon fibers and resins to form high-performance composite products.

Advantages of Using a Composite Press to Form Carbon Fiber Products

There are many advantages to using a composite press to form carbon fiber products.

1. The carbon fiber material itself has excellent properties, such as lightweight, high strength, and rigidity, which makes the final product have obvious advantages in weight and is especially suitable for fields requiring weight reduction.

2. The composite material press can fully combine carbon fiber with resin, eliminate air bubbles and defects, and improve the strength and toughness of the product. This optimized combination makes carbon fiber products perform well in applications with high strength requirements, such as aircraft parts in the aerospace field.

3. In addition, the mass production capability of composite presses offers the possibility of large-scale manufacturing of carbon fiber products. With the continuous development of technology, production efficiency, and output have been continuously improved, which has gradually reduced the cost of carbon fiber products and promoted its wide application in the market.

Future Prospects and Conclusions

With the advancement of science and technology and the increasing demand for high-performance materials, carbon fiber, and its composite products will be more widely used in various fields. As the key process equipment for carbon fiber forming, the composite material press will continue to play an important role. With the continuous innovation and improvement of press technology, we can foresee that the performance of carbon fiber products will be further improved, and the application range will continue to expand.

Overall, the high-performance collaboration of carbon fiber and composite presses opens up unprecedented opportunities for modern manufacturing. In the context of increasing global demand for sustainable development and efficient use of resources, the wide application of carbon fiber products will help promote technological innovation and industrial upgrading in various fields. I believe that in the future, carbon fiber will continue to lead the development of material science and become one of the main driving forces for high-performance materials in the new era.

Zhengxi is a professional manufacturer of hydraulic equipment, providing composite hydraulic presses of various tonnages. If you have any needs, please contact us.

Post time: Jul-28-2023