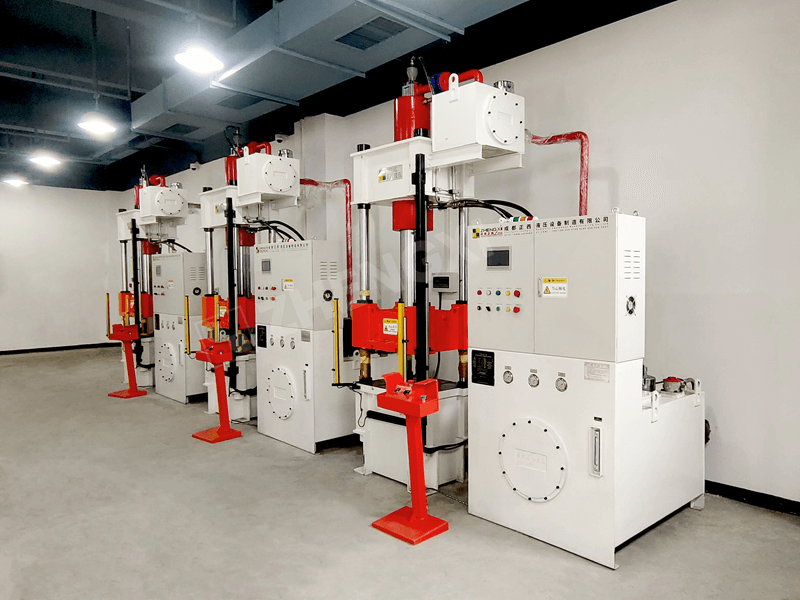

630-tons Salt Brick Press Machine

The salt brick press, also known as a salt lick press, is a fully automatic hydraulic press with a four-beam, four-column structure. It is primarily used to press powdered products (such as livestock salt, nutrient salt, and mineral salt) into shapes for easy storage and for livestock such as cattle and sheep to lick for trace element supplementation. Commonly used salt bricks for livestock farming on the market are available in 2.5 kg, 5 kg, and 10 kg sizes. Based on customer demand, salt brick presses are available in capacities of 315, 400, 500, 630, 800, and 1000 tons.

Working Principle: A hydraulic transmission system transmits pressure to the mold, pressing and shaping the raw material.

Main Functions: Automatic material placement, pressing, demolding, and block pushing, eliminating the need for manual operation.

Applications: Suitable for pressing and shaping cattle licks, sheep licks, nutritional licks, feed licks, mineral licks, fattening licks, and salt licks.

Structural Features of the 630-ton Salt Brick Press Machine

1. Four-beam, Four-column Structure: The machine utilizes a four-beam, four-column hydraulic press, offering high power, precise positioning, and fully automatic control.

2. PLC Hydraulic Drive System: The advanced PLC hydraulic drive system enables fully automated control, reducing labor costs and improving production efficiency.

3. High-Quality Hydraulic Components: The machine uses high-quality components, ensuring continuous operation. It can be equipped with different molds to produce a variety of product shapes, offering high versatility.

4. Independent power and electrical control systems: The machine features independent power and electrical control systems, simplifying operation and reducing machine failure rates.

Technical Parameters of the 630-ton Salt Brick Machine

Nominal Pressure: 6300 kN

Working Pressure: Typically 25 MPa

Worktable Dimensions: Left and Right Edges × Front and Rear Edges: 1500 mm × 1200 mm (Specific dimensions may vary by manufacturer)

Opening Height: Typically 1600 mm

Slider Stroke: 800 mm

Ejection Cylinder: 160 T

Ejection Cylinder Stroke: 300 mm

Maximum Downward Speed: 200 mm/s

Feed Speed: 10-22 mm/s

Salt Brick Production Line Components

The salt brick production line primarily consists of a mixer, feed pipe, storage silo, a 630-ton salt brick machine, an automatic sealing and cutting machine, a conveyor belt, and heat shrink tape. The mixer, feed pipe, and storage silo are available in stainless steel or carbon steel, allowing users to choose the material that best suits their needs.