Salt block hydraulic press

ZHENGXI HYDRAULIC special design the Yz 79 hydraulic press for SALT BLOCKS.

Whatsapp: +86 176 0282 8986

Key Features

1.Main frame material: use steel #Q345B to structure the main body of machine instead of common material steel#Q235 in the market. Body Toughness increase 1.5 times than normal machine in the market.

2.Corrosion protection: Considering the corrosive nature of salt, hopper and loading system are made of 304 stainless steel.

3.Automatic feeding: There is a sensor in the hopper of loading system, when there is no enough salt, the system will the start screw feeder.

4.Quality control: The device is equipped with a pressure alarm device. When the machine is pressed to the predetermined position and the pressure is not reached, the device will give an alarm to remind the operator to check the density of the product.

5.Servo System:

a.Energy saving: use servo motor, pump, for hydraulic press to reach the energy saving target. Energy saving reach 40%-70%, save a lot of money on power rate for buyer in future’s long time using.

b.Unstable voltage input adaptation: Rated voltage: Three-phase 380-480V 50Hz/60Hz, Allowable voltage fluctuation range 323-528V 50Hz/60Hz. Perfect working in area/situation which can’t provide stable power.

c.Fast Speed & High Accuracy: pressure raise to 20Mpa response time 50ms, pressure relief time 60ms, entire machine output speed increase around 10%. Pressure accuracy +-0.5kgf, highly reduce the failure rate in production and improve product quality.

d.Long using life: Slow overheat, lower noisy. Slow overheat the motor and hydraulic oil in long time using, protect the ware parts like seals. Prolong the entire machine’s using life.

e.Easy maintains: considering the servo system programmer is rare to be found, maintains may be hard to customer so we replace the servo computer instead of PLC which are common to use in machine, make customer can easy maintains the machine in Local.

6.Structure: Fitted with calibration valve and a three position driven distributer, complete with oil and capstan for hoisting worktable. 4 column type structure, simple, economic and practical.

7.Safety design: Equipment with mechanical limit device to prevent damage to the mold. With photoelectric protection and a safety fence, to prevent safety accidents.

8.After-sale service:

a.during warranty ZHENGXI will take full responsibility of customer’s machine, ANY parts have problem ZHENGXI will send new FREE replacement to customer, the freight of replacement are also covered by ZHENGXI.

b.Door-to-door service are payable and optional to be provide for installation, commissioning, maintains, training purpose. Charge of door-to-door service will be given in next stage.

c.Technical support by email, phone or video call are FREE and lifetime available.

On-site service charges $200 per technical staff per day.

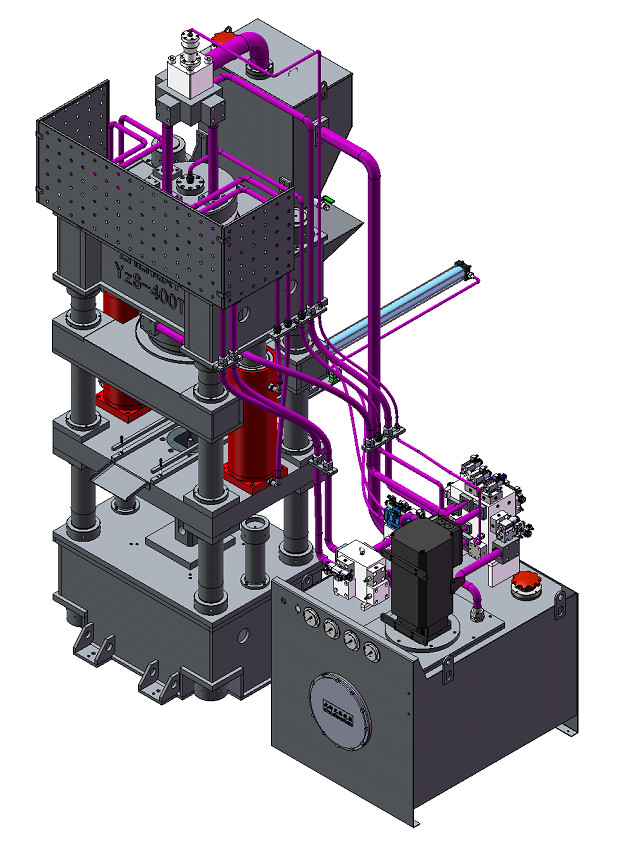

3D Drawing

It is fully automatic equipment, automatic loading and unloading. The machine is equipped with an automatic cooling system, which can produce continuously for 24 hours.

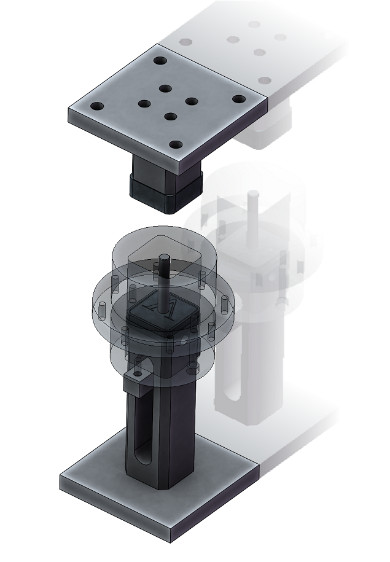

Mold Details

Pillar

The guide columns (pillars) will be made of C45 hot forging steel and have a hard chrome coating thickness 0.08mm. And do hardening and tempering treatment.

Application

This machine is mainly suitable for slat block forming; the equipment has good system rigidity and high precision, high life and high reliability. The process for hot press forming meets 3 shifts/day production.

Manufacturing Standards

| JB/T3818-99 《Technical conditions of hydraulic press》 |

| GB/T 3766-2001 《General technical requirements for hydraulic systems》 |

| GB5226.1-2002 《Safety of machinery-Mechanical and electrical equipment-Part 1: General technical requirements》 |

| GB17120-97 《Press machinery safety technical requirements》 |

| JB9967-99 《Hydraulic machine noise limit》 |

| JB/T8609-97 《Press machinery welding technical conditions》 |

Main Body

The design of the whole machine adopts computer optimization design and analyzes with finite element. The strength and rigidity of the equipment are good, and the appearance is good. All welded parts of the machine body are welded by high-quality steel mill Q345B steel plate, which is welded with carbon dioxide to ensure the welding quality.

Cylinder

|

Parts |

Feature |

|

Cylinder Barrel |

|

|

Piston Rod |

|

|

Seals |

Adopt Japanese NOK brand quality sealing ring |

|

Piston |

Guided by copper plating, good wear resistance, ensuring long-term operation of the cylinder |

Servo System

1.Servo System Composition

Principle of Servo Control

The main cylinder upper chamber equipped with pressure sensor, slide equipped with displacement sensor controller. According to the pressure feedback signal, the position feedback signal, pressure given signal, position given signal and speed given signal to calculate the rotational speed of the servo motor, to control the pump output for pressure, speed and position control.

The press adopts PID to adjust the pressure and position, through the speed of the servo motor to precede the closed-loop control. By adjusting the speed of the servo motor, it can control the pressure, speed, position and other parameters of the hydraulic press, by eliminating the pressure control valve, flow control valve and other components in the hydraulic control circuit to be simplify.