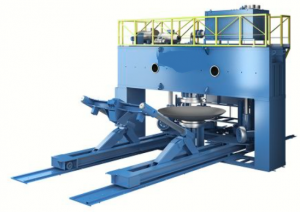

Dish end press machine

The head refers to the end caps at both ends of the metal closed container. It is mainly the head of the metal cylindrical container. It is an indispensable and important component in pressure vessel equipment in many industries from petrochemical, and atomic energy to food and pharmaceutical industries. It is related to the long-term safe and reliable operation of pressure vessels. The material of the head is mostly carbon steel, stainless steel, alloy steel, etc. The production of heads is generally stamped or stretched using a dish-end hydraulic press.

Zhengxi‘s dish end press has the characteristics of high production efficiency and good molding effect. It is mainly used for cold-pressed heads of various tank trucks, and can also be used for medium and thin plate forming, stretching, correction, and other processes within the parameter range. The metal head forming presses we produce mainly include 630 tons, 2000 tons, 4000 tons, and 9000 tons, etc. We can also design, develop, manufacture, install and debug dish end press machines of other specifications according to customer needs.

Advantages of 5000-ton Dish End Press Machines:

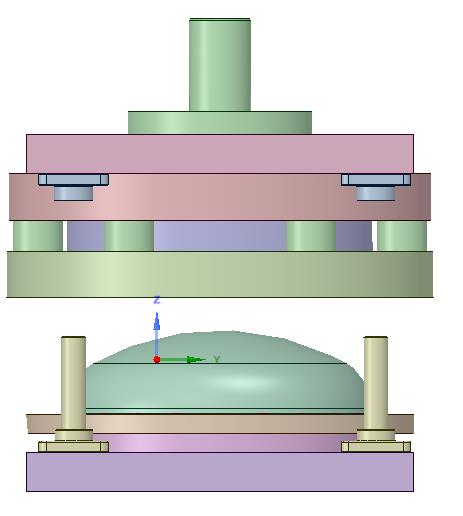

1. The fuselage adopts a vertical four-beam and four-column structure with good rigidity. The slider guide adopts an elongated structure and has high guide precision.

2. The locking nut has an anti-loosening structure and good accuracy retention. The press is equipped with a lower hydraulic pad and an upper striking rod.

3. The oil cylinders all use imported sealing components to ensure reliable sealing performance.

4. The piston rod is made of high-quality carbon steel forgings with surface quenching treatment. The piston head adopts an integral structure, which is safer and more reliable than the threaded split piston head.

5. The hydraulic and electronic controls are integrated and installed, the press occupies a small area, the appearance is beautiful, and the press installation does not require a pit.

6. The hydraulic control adopts a cartridge valve integrated system, which is reliable in action and easy to maintain.

7. The working pressure and working stroke of this dish end press can be adjusted within the parameter range according to the usage requirements.

8. The metal tank head forming machine is equipped with photoelectric protection, making the operation safe and reliable.

9. The electronic control device can realize the lifting and clamping of the workbench and move it in and out towards the front of the fuselage.

10. It is equipped with a flexible control system in which the tensile force floats with the blank holder force, changing the traditional hot press forming process of the head. By utilizing the flexible control that the tensile force floats with the blank holder force, the ideal extension curve for cold stretching of thick plates can be controlled.

11. The dish end press machine is equipped with an edge holder beam and a tensile beam. During the stretching process, the tensile and edge holder force are proportionally adjusted in the range of 0 to 25Mpa according to process needs.

Types of Dish End Presses

1. Hot press dish end hydraulic press

It is fast and flexible in application range, has high production reliability, and is economical and applicable.

■ Suitable for hot press head forming

■ The press structure adopts the four-column structure

■ The holder slider is equipped with a radially moving adapter

■ The stroke of the blank holder cylinder is adjustable

■ The blank holder force and stretching force can be adjusted automatically

■ Can realize single action and double action respectively

2. Cold press dish end hydraulic press

■ Suitable for cold press head forming

■ The press structure adopts the four-column structure

■ The stretching machine is equipped with an upper mold, lower mold, mold connection, and quick-change device

■ The blank holder force and stretching force can be adjusted automatically

Main Technical Parameters of Dish End Press Machine

| Main parameters | Unit | Numerical value | |||

| Nominal force | KN | 20000 | 50000 | 100000 | |

| Liquid pressure | Mpa | 90 | 78.5 | 60.5 | |

| Slider stroke | mm | 300 | 400 | 800 | |

| Slider speed | Fast descent | mm/s | 10 | 40 | 60 |

| Work progresses | mm/s | 1-1.5 | 0.6 | 0.2-0.3 | |

| Return trip | mm/s | 20 | 100 | 100 | |

| Maximum closed height | mm | 700 | 1100 | 2500 | |

| Minimum closed height | mm | 400 | 700 | 1700 | |

| Effective area of workbench (left and right*front and back) | mm | 1030 x 800 | 1200 x 1200 | 2000 x 2000 | |

| Motor power | KW | 30 | 45 | 220 | |

| Machine dimensions (front and rear*left and right*height) | mm | 1430 x 800 x 3650 | 1940 x 1200 x4683 | 2000 x 3060 x8000 | |

Zhengxi is a professional hydraulic press factory in China and provide high-quality dish end press machine. If you have any needs, contact us!