FRP hydraulic press is a forming machine that uses hydraulic system pressure to press FRP/GRP composite materials into septic tanks, water tanks, manhole covers, flower pots, and other products. FRP/GRP machines for panel tanks are often used in press-forming processes. An FRP-forming hydraulic press can produce FRP water tank products of different sizes and specifications by replacing molds of different shapes.

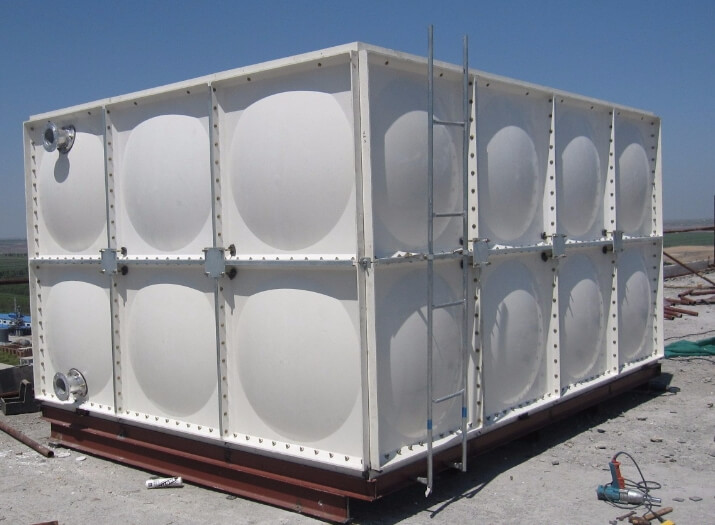

A fiberglass water tank is a new type of water tank commonly used internationally. Its unique performance solves the problems of the heavy weight of the condensate water tank, easy leakage, easy growth of moss, easy rust of the steel plate water tank, and the pollution of water quality caused by the anti-rust coating. It has the advantages of good water quality, no leakage, lightweight, beautiful appearance, long service life, and easy installation.

Zhengxi Hydraulic Equipment Co., Ltd. provides FRP/GRP machines for panel tanks in various tonnages such as 200 tons, 315 tons, 500 tons, and 630 tons. It can press and form products in one go. In addition, the forming press can also choose between a four-column structure and a frame structure.

Our FRP/GRP machines for panel tanks have an independent power mechanism and electrical system. Using button centralized control, three working modes of adjustment, manual and semi-automatic can be realized. The machine’s working pressure, pressing speed, no-load rapid descent, and deceleration stroke and range can be adjusted according to process requirements to complete the ejection process. There are two process modes: the ejection process and the stretching process. Each process has two process actions: constant pressure and fixed stroke. The constant pressure molding process has an ejection delay and automatically returns to the position after pressing.

Processing Technology of FRP/GRP Machines for Panel Tanks

A certain amount of FRP/GRP composite material is placed into a pair of metal molds. Under a certain temperature and pressure, the composite material is heated and plasticized in the mold cavity, and the pressure creates a flow that fills the mold cavity and causes the resin to undergo a curing reaction. When the composite material flows and fills the mold cavity, not only the resin flows, but the reinforcing materials also flow so that the resin and fibers fill all parts of the mold cavity at the same time.

Structural Features of FRP/GRP Machines for Panel Tanks

1. The structural design of the FRP water tank forming hydraulic press is computerized. The machine tool has a simple structure and is economical and practical.

2. The hydraulic control adopts a cartridge valve integrated system, which has reliable action, long service life, small hydraulic impact, and reduces connecting pipelines and leakage points.

3. The independent electrical control system makes the equipment work reliably, operate reliably, and maintain easily.

4. Through the operation panel, two molding processes of fixed stroke and constant pressure can be realized. And it has functions such as maintaining rolling time.

5. The working pressure of the slider, the stroke range of no-load rapid downward movement, and the slow forward movement of FRP/GRP machines for panel tanks can be adjusted according to process requirements.

Zhengxi Hydraulic Equipment Manufacturing Co., Ltd. is a company focusing on the research and development, production, and service of large and medium-sized hydraulic press equipment. The annual output value is nearly 400 million yuan, and the factory area is more than 30,000 square meters. The main products include composite material hydraulic presses, metal drawing hydraulic presses, fiberglass molding hydraulic presses, hot die forging hydraulic presses, forging presses, and various supporting molds (blanking, drawing, molding, forging), etc. Customers cover more than 300 cities in China and overseas regions such as Central Asia, Europe, Africa, and South America. If you have any needs, please contact us today.

Post time: Oct-12-2023