Industry News

-

Compression Process of 1000 Tons Carbon Fiber Composite Forming Hydraulic Press

Carbon fibers are mainly a special fiber composed of carbon elements, which varies depending on the kind of carbon, generally 90% or more. Carbon fibers have characteristics of general carbon materials such as high temperature resistance, friction, conductive, thermal conductivity, corrosion resi...Read more -

315 tons of fusion material hot press manual production and advantages

The composite resin manhole cover is divided into the SMC resin manhole cover and BMC resin manhole cover according to the raw material structure, after the hydraulic and mold quickly mold can be formed once. It is generally use 315T four-column press machine according to the size of the manhole ...Read more -

Composite hydraulic press scope application

The composite series hydraulic press products are suitable for the molding of thermosetting and thermoplastic products in the automotive, aerospace, home appliances, military and other industries. There are many types of composite materials. At present, the composite materials widely used in hydr...Read more -

The temperature influence for SMC molding products

The temperature change during the molding process of FRP is more complicated. Because plastic is a poor conductor of heat, the temperature difference between the center and the edge of the material is large at the beginning of molding, which will cause the curing and cross-linking reaction to not...Read more -

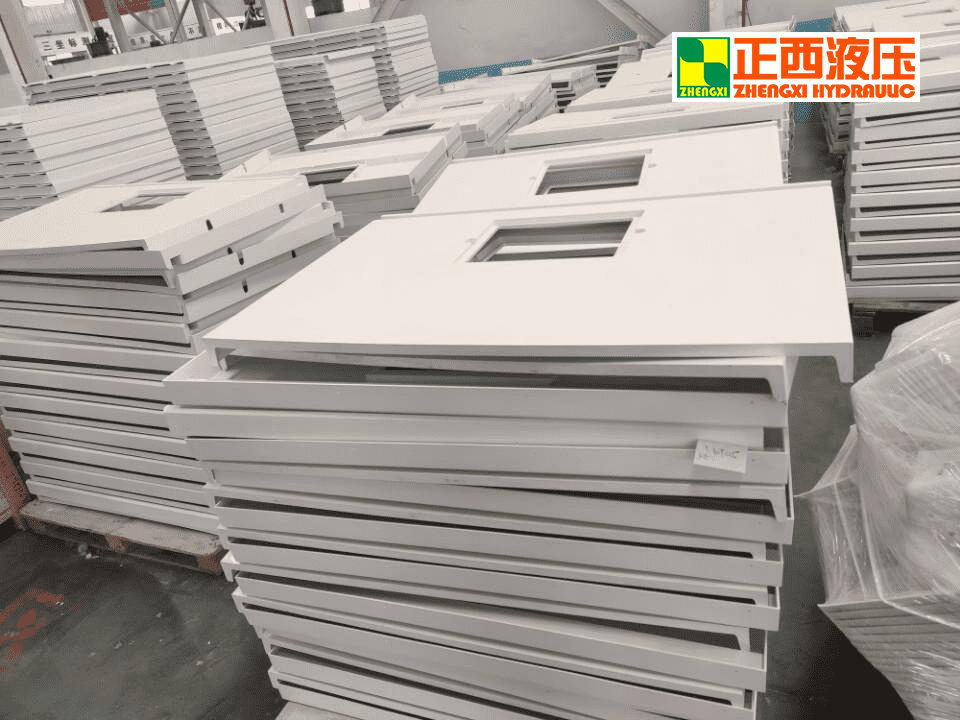

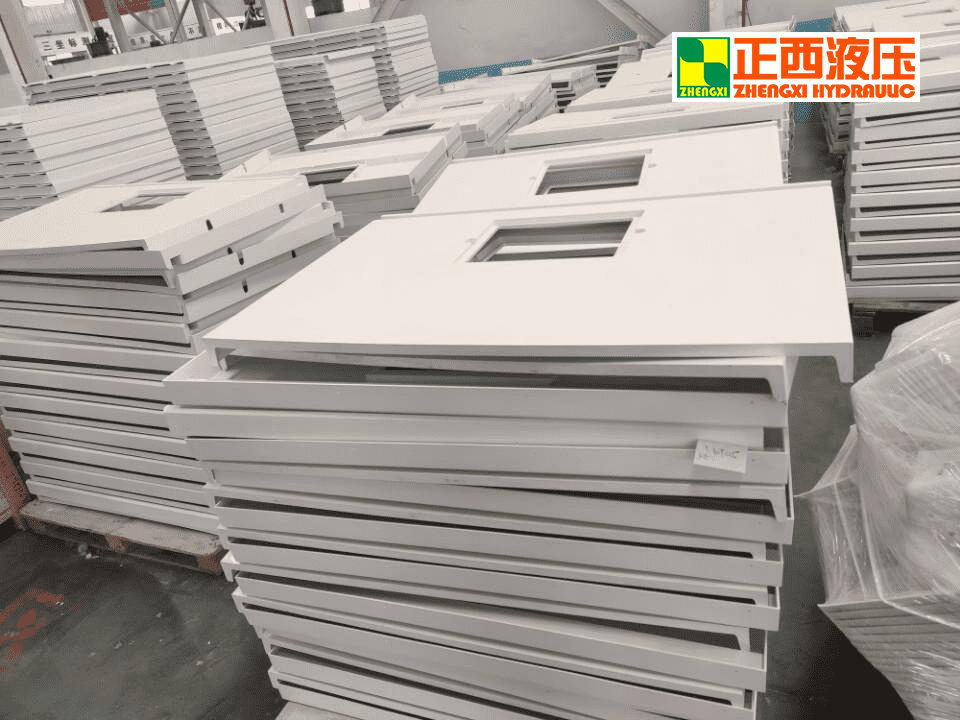

SMC molding automotive panels advantages and application

SMC automobile covering parts have the advantages of corrosion resistance, aging resistance, easy cleaning, light weight, high elastic modulus, etc., and are the best choice for automobile covering parts. Automobile covering parts (hereinafter referred to as covering parts) refer to the automobil...Read more -

The difference between electric heating plate and thermal oil heating mould

Analysis of main problems and solutions of electric heating plate: 1. The heating temperature of the electric heating plate cannot meet the requirements a. With the continuous improvement of the current process, the equipment cannot meet the product molding requirements; b. The heating uniformity...Read more -

SMC BMC Applications

This manual sets out to describe Sheet Moulding Compound (SMC) and Bulk Moulding Compound (BMC), their composition, characteristics, processing, end-uses and recycling. Recommendations are given on how to achieve the best results and how to maximise the benefits that these unique m...Read more -

What are the main features of metal deep drawing automotive stamping parts in the auto industry?

The metal deep drawing stamping part is a forming method of a workpiece (pressing part) of a desired shape and size by applying an external force to a plate, a strip, a pipe, a profile, and the like by a press and a die(mould) to cause plastic deformation or separation. Stamping and forging are t...Read more