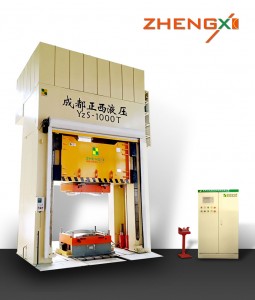

U-shaped Drainage Ditch Forming Hydraulic Press

A U-shaped drainage ditch forming hydraulic press is a piece of equipment used to manufacture U-shaped resin drainage ditches. It uses hydraulic force to bend resin sheets into U-shaped shapes for drainage in drainage systems or other engineering projects.

Drainage ditches are divided into U-shaped composite resin drainage bubbles, fiberglass resin drainage ditches, etc. according to the material. They are all hot-pressed and formed under the action of a hydraulic press and a mold. Therefore, this equipment is also called a U-shaped drainage ditch forming hydraulic press and molded composite material forming hydraulic press.

The molded drainage ditch production process is to put a certain amount of prepreg into the mold control of the metal mold. A hydraulic press is used to generate a certain temperature and pressure. After the mold is closed, under a certain temperature and pressure, the prepreg is heated, softened, flowed under pressure, filled into the mold cavity, formed and solidified in the mold cavity, thereby obtaining the finished composite drainage ditch product. The equipment is simple to operate, has a simple process, and is highly efficient. It is the most widely used press equipment for molding composite materials.

Which Type of U-shaped Drainage Ditch Production Equipment is Suitable?

According to the drainage ditch molding process, there are four-column and frame-type molding hydraulic presses. According to customer purchase cases, this hydraulic press for U-shaped drainage ditch mostly adopts a three-beam and four-character structure. Four-column guide ensures accurate mold closing. Equipped with a servo CNC system, it has low operating noise, smooth operation, and more precise control.

The U-shaped composite resin drainage ditch molding process can meet various requirements of the pressing process. The pressure design of three stages of pre-pressure, molding and pressure-holding is adopted, and the pressure is scientifically distributed by time segments, making the energy efficiency of the equipment more significant. The molding pressure is high and reliable, ensuring the molding quality of U-shaped composite resin drains.

U-shaped composite resin drainage ditch production equipment has a high degree of automation, a short production cycle, and high production efficiency.

Characteristics of Hydraulic Press for U-shaped Drainage Ditch:

1. Adopt PLC control. The equipment temperature, curing time, pressure, and speed conform to the process characteristics of the material. Easy to operate and adjustable working parameters.

2. This equipment can optionally be equipped with an in-mold core pulling control system. Preset in-mold ejection control system. It can realize a series of actions such as downward movement, segmentation, and suppression, segmentation deflation, working, pressure maintaining, slow opening, return, slow demoulding, ejection, ejection stay, and retreat. And the temperature can be controlled at multiple points.

3. Hydraulic control adopts a cartridge valve integrated system. It has reliable action, small hydraulic impact, long service life, and few leakage points. Reduces connecting pipes and leak points.

4. The molding power adopts a special gas-liquid booster cylinder. Its characteristics are: fast and stable. The quality and production efficiency of molded products are guaranteed.

5. Human-machine interface control, centralized button control. Adjustable and semi-automatic operation modes can be realized. The rotary encoder is used to realize automatic feedback control of the slider’s stroke to ensure the consistency of the slider’s operating stroke. With hydraulic compression device.

Applications of U-shaped Drainage Ditch Forming Hydraulic Press

Hydraulic press for U-shaped drainage ditch plays an important role in various scenarios. Here are some common applications:

1. Construction projects: On construction sites, U-shaped gutters are widely used in drainage systems to ensure that rainwater and wastewater can be effectively drained and to prevent water from damaging the foundation and structure of the building. Hydraulic presses are used to manufacture the U-shaped sections of these gutters, ensuring that their shape and size meet engineering requirements.

2. Road and bridge construction: U-shaped drainage ditches are also widely used in road and bridge construction to facilitate drainage and prevent roads and bridges from water damage. Hydraulic presses are used to produce the U-shaped sections of these gutters, ensuring their quality and reliability.

3. Industrial Facilities: Industrial facilities often require drainage systems to handle the liquid waste generated during production processes. U-shaped drainage ditch forming hydraulic press can be used to manufacture industrial drainage ditches to ensure that liquids inside the factory can be effectively discharged and treated.

4. Urban Infrastructure: In urban infrastructure projects, such as the construction of parks, parking lots, and sidewalks, U-shaped gutters are used to manage stormwater and wastewater flows. Hydraulic presses for U-shaped drainage ditches are used to create these gutters to ensure the sustainability of urban infrastructure.

Zhengxi Hydraulic Equipment Manufacturing Co., Ltd. designs and produces U-shaped drainage ditch-forming hydraulic presses with different structures according to different specifications and sizes of resin drainage ditches, including four-column type and frame type. Common tonnages of molded composite material forming hydraulic presses include 400 tons, 500 tons, 800 tons, 120 tons hydraulic presses, etc. Machine parameters such as table size, opening, stroke, speed, etc. can be customized according to customer requirements. Contact us for more information.