I-Cold forging kunye ne-hot forging ziinkqubo ezimbini ezibalulekileyo eziqhelekileyo kwintsimi yesinyithi.Banomehluko omkhulu kwiplastiki yezinto, iimeko zobushushu, i-microstructure, kunye noluhlu lwesicelo.Kule nqaku, siza kuxubusha ngokweenkcukacha iimpawu zezi nkqubo zimbini, kunye nokusetyenziswa koomatshini ababandayo kunye nokushisa okutshisayo kwimveliso yangempela.

Umahluko phakathi kokubumba okubandayo kunye nokutshisa okushushu

Cold forging ibhekisa kwiinkqubo yokubumbaiqhutywe kwiqondo lokushisa, kwaye iqondo lokushisa lentsimbi yokusebenza liphantsi kunokushisa kwe-recrystallization.Ngenxa yeplastiki ehlwempuzekileyo yemathiriyeli kumaqondo obushushu aphantsi, ukubunjwa okubandayo kudla ngokufuna amandla amakhulu ukwenza i-deformation yeplastiki.Ke ngoko, i-forging ebandayo ifanelekile kwizixhobo ze-alloy ezinamandla aphezulu.I-Hot forging yinkqubo yokubumba eyenziwa phantsi kweemeko eziphezulu zokushisa, kwaye iqondo lokushisa le-workpiece yesinyithi liphezulu kunokushisa kwe-recrystallization.Kwiqondo lokushisa eliphezulu, isinyithi sineplastiki efanelekileyo, ngoko ke i-forging eshushu ifuna ukusebenzisa amandla amancinci, afanelekileyo kwiindidi ezahlukeneyo zezixhobo zetsimbi.

Umahluko weqondo lokushisa phakathi kokubumba okubandayo kunye nokutshisa okutshisa kunempembelelo ebalulekileyo kwi-microstructure yezinto.Ngexesha lokubumba okubandayo, iinkozo zetsimbi azikwazi ukuphinda zenziwe kwakhona, ngoko ke i-morphology yeenkozo zokuqala zihlala zigcinwa emva kokubanda okubandayo.Kwinkqubo yokutshisa okutshisayo, iinkozo zetsimbi zilula ukuphinda zenziwe kwakhona kumaqondo okushisa aphezulu, ngoko ke ukufana okufanayo kunye nesakhiwo sengqolowa esicolekileyo sihlala sifumaneka emva kokutshisa okutshisa.Ke ngoko, ukubumba okushushu kunokuphucula ukuqina kunye neplastikhi yezinto.

Ukongeza, ukubumba okubandayo kunye nokutshisa okushushu kunoluhlu oluhlukeneyo kwisicelo esisebenzayo.Ukubumba okubandayo kusetyenziswa ikakhulu ukwenza i-alloy workpieces enamandla amakhulu kunye neplastiki ephantsi, njengentsimbi ephezulu.Ngenxa yokuba ukubunjwa okubandayo kufuna ukusetyenziswa kwamandla amakhulu, ngokuqhelekileyo kusetyenziselwa ukwenza izixhobo zokusebenza ezincinci nezilula.I-Hot forging ifanelekile kwizinto ezininzi zetsimbi.Iyakwazi ukuvelisa izixhobo zokusebenza ezinemilo enzima kwaye inokuphucula ukuqina kunye neplastiki yezinto.Isetyenziswa kakhulu ekwenzeni izixhobo ezinkulu zemizi-mveliso ezifana neendawo zemoto, iindawo ze-aerospace, kunye noomatshini bobunjineli.

Umatshini wokubumba obandayo kunye nomatshini wokubumba oshushu

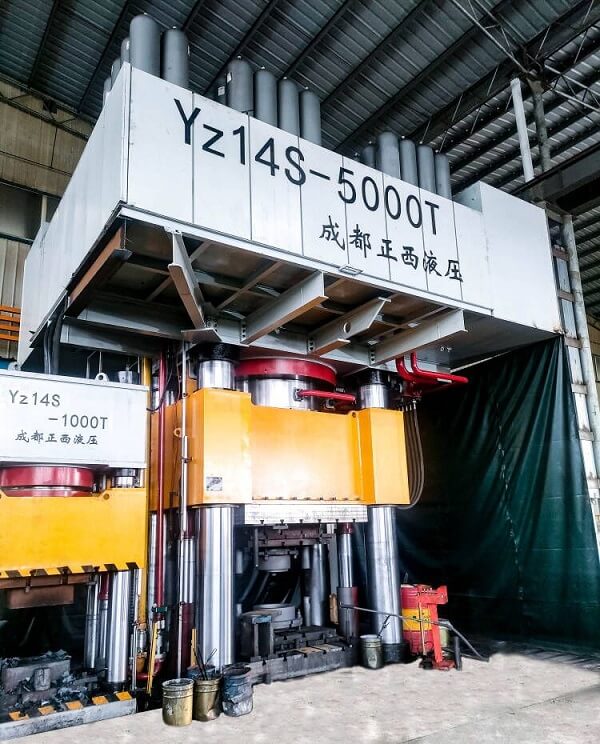

A umatshini wokubumba obandayosisixhobo esikhethekileyo senkqubo yokubumba ebandayo, uphawu lwalo oluphambili kukuba lunokwenza isinyithi sokubumba kwiqondo lokushisa.Oomatshini bokubumba ababandayo ngokubanzi babandakanya oomatshini bokubumba ababandayo behydraulic kunye noomatshini bokubumba ababandayo.Umatshini wokubumba obandayo wehydraulic uqhuba inkqubo yokubumba ngenkqubo yehydraulic, enegunya elikhulu lokubumba kunye nokuguquguquka kwaye inokusetyenziselwa ukwenza izinto zokusebenza ezinobungakanani obahlukeneyo.Umatshini wokubumba obandayo womatshini uyayiqonda inkqubo yokubumba ngokuhanjiswa koomatshini.Xa kuthelekiswa nomatshini wokubumba obandayo wehydraulic, amandla awo okubumba mancinci, kodwa aneenzuzo kwezinye izicelo ezithile.

Umatshini oshushu wokubumba sisixhobo esikhethekileyo senkqubo yokutshisa i-hot forging kwaye unokwenza isinyithi sokubumba phantsi kweemeko eziphezulu zokushisa.Ngokuqhelekileyo ithatha i-hydraulic okanye i-mechanical transmission.Kwaye iintlobo ezahlukeneyo zoomatshini zikhethwa ngokuhambelana namandla afunekayo okubumba kunye neemfuno zenkqubo.Iumatshini wokushicilela oshushuifudumeza i-workpiece yentsimbi ngaphezu kweqondo lobushushu le-recrystallization ukuyenza ifikelele kwiplastiki elungileyo kwaye emva koko isebenzise amandla afanelekileyo ukugqiba inkqubo yokubumba.

Kwimveliso yokwenyani, bobabini oomatshini bokubumba ababandayo kunye noomatshini abashushu bokubumba badlala indima ebalulekileyo.Umatshini wokubumba obandayo ufanelekile kwizixhobo ze-alloy ezineemfuno eziphantsi zeplastiki kunye neemfuno zamandla aphezulu.Ngokuqhelekileyo isetyenziselwa ukuvelisa ama-workpieces amancinci amancinci, njengama-bolts, amantongomane, njl njl.Iyakwazi ukwenza izinto zokusebenza ezinobungakanani obukhulu kunye nezintsonkothileyo, ezinjengee-crankshafts zemoto kunye neendawo ze-injini yomoya.

Ukushwankathela, ukubumba okubandayo kunye nokutshisa okutshisayo ziinkqubo ezimbini eziqhelekileyo ekubunjweni kwesinyithi.Kwaye banomahluko omkhulu kubushushu, iplastiki yezinto, i-microstructure, kunye noluhlu lwesicelo.I-Cold forging ifanelekile kwizixhobo ze-alloy ezinamandla aphezulu kunye neplastiki ephantsi, ngelixa i-forging eshushu ifanelekile kwiindidi ezahlukeneyo zetsimbi, ngakumbi ezo zifuna ukuphucula ukuqina kunye neplastiki.Oomatshini bokubumba ababandayo kunye noomatshini bokubumba abashushu zizixhobo ezikhethekileyo ezisetyenziselwa ukuqonda ezi nkqubo zimbini.Badlala indima ebalulekileyo kwintsimi yesinyithi, ukubonelela ngeendawo eziphezulu zetsimbi kumashishini ahlukeneyo.

UZhengxi uqondiswe kakuhleUmenzi woomatshini bokushicilela eTshayina, ukubonelela ngoomatshini bokubumba ababandayo abakumgangatho ophezulu kunye noomatshini bokubumba abashushu.Ukuba unazo naziphi na iimfuno, nceda uqhagamshelane nathi ngoko nangoko.Iingcali zethu ziya kukubonelela ngezisombululo ezigqibeleleyo zoshicilelo lwe-hydraulic.

Ixesha lokuposa: Aug-04-2023