Ukukhucululwa okubandayo nokuvutha okushisayo kuyizinqubo ezimbili ezibalulekile ezivamile emkhakheni wezenkolo ezazikhohla.Banomehluko omkhulu eplastikini yezinto ezibonakalayo, izimo zokushisa, i-microskruction, kanye nobubanzi bezicelo.Kulesi sihloko, sizoxoxa ngokuningiliziwe izici zalezi zinqubo ezimbili, kanye nokusetshenziswa kwemishini ebandayo nevuthayo ekukhiqizweni kwangempela.

Umehluko phakathi kwe-forging ebandayo kanye ne-hot forging

Cold forging ibhekiselaInqubo yokwakhaokwenziwa ekamelweni lokushisa, futhi izinga lokushisa lensimbi yokusebenza liphansi kunokushisa kwe-recrystallization.Ngenxa ye-plasticity empofu yezinto emazingeni okushisa aphansi, ukubumba okubandayo kuvame ukudinga amandla amakhulu ukwenza ukuguqulwa kwepulasitiki.Ngakho-ke, ukubumba okubandayo kulungele izinto ze-alloy ezinamandla aphezulu.Ukuvuselelwa okushisayo kuyinqubo ebikwe ngaphansi kwezimo zokushisa okuphezulu, futhi izinga lokushisa lomsebenzi wensimbi liphakeme kunamazinga okushisa kabusha.Emazingeni okushisa aphezulu, insimbi ine-plastiki enhle, ngakho-ke ukudala okushisayo kudinga ukufaka amandla amancane, alungele izinhlobo ezahlukahlukene zezinto zensimbi.

Umehluko wezinga lokushisa phakathi kokukhanga okubandayo kanye ne-hot forging unomphumela obalulekile ku-microstructure yezinto.Ngesikhathi sokubanda okubandayo, okusanhlamvu kwensimbi akuthambekele ekubunjweni kabusha, ngakho-ke i-morphology yama-grain angempela ivame ukugcinwa ngemuva kokubanda.Enqubweni yokwakha esishisayo, okusanhlamvu kwensimbi kulula ukuwaphindaphinda amazinga okushisa aphezulu, ngakho-ke isakhiwo esilinganiselwe nesinhlamvu esisezingeni eliphezulu sivame ukutholwa ngemuva kokushisa.Ngakho-ke, ukubumba okushisayo kungathuthukisa ukuqina kanye ne-plasticity yezinto.

Ngaphezu kwalokho, ukucebisisa okubandayo nokuvuselelwa okushisayo kube namabanga ahlukile ngohlelo lokusebenza olusebenzayo.Ukuqinisekiswa okubandayo kusetshenziselwa ikakhulukazi ukukhiqiza ama-arvices we-alloy ngamandla aphezulu kanye neplastiki ephansi, njengensimbi enamandla.Ngenxa yokuthi i-cold forging idinga ukusetshenziswa kwamandla amakhulu, ngokuvamile isetshenziselwa ukwakha izingcezu zokusebenza ezincane nezilula.Ukuvuza okushisayo kulungele izinto eziningi zensimbi.Kungenza ama-WorkPeices ngezimo eziyinkimbinkimbi futhi kungathuthukisa ubunzima nobunzima bezinto zokwakha.Kusetshenziswa kabanzi ekwenziweni kwemishini emikhulu yezimboni efana nezingxenye ze-auto, izingxenye ze-aerospace, nemishini yobunjiniyela.

Umshini wokubumba obandayo kanye nomshini wokubumba oshisayo

A umshini wokubumba obandayoIngabe imishini ekhethekile yenqubo ebandayo yokwakha amandla, isici sayo esiyinhloko ukuthi singakwenza ukufeza insimbi yokushisa egumbini lokushisa.Imishini ebandayo ebandanda ihlanganisa imishini ebandayo ye-hydraulic ebandayo kanye nemishini ebandayo yemishini ebandayo.Umshini wokubanda we-hydraulic obandayo ushayela inqubo yokwakha ngohlelo lwe-hydraulic, olunamandla amakhulu okuvuselela kanye nokuvumelana nezimo futhi angasetshenziswa ukwenza imisebenzi yobungani obuhlukahlukene.Umshini wokubumba obandayo osebenza ngomshini uqaphela inqubo yokubumba ngokudlulisela ngomshini.Uma kuqhathaniswa nomshini wokubumba obandayo we-hydraulic, amandla awo okubumba mancane, kodwa anezinzuzo kwezinye izinhlelo zokusebenza ezithile.

Umshini wokuvuselela oshisayo yimishini ekhethekile yenqubo yokuvuselela okushisayo futhi ungafeza izinsimbi zensimbi ngaphansi kwezimo zokushisa okuphezulu.Ivamise ukusebenzisa i-hydraulic noma i-mechanical transmission.Futhi izinhlobo ezahlukene zemishini zikhethwa ngokuya ngamandla okubumba adingekayo kanye nezidingo zenqubo.IUkushisa Ukucindezelaifudumeza i-workpiece yensimbi ngaphezu kwezinga lokushisa le-recrystallization ukuze ifinyelele ipulasitiki enhle bese isebenzisa amandla afanele ukuqedela inqubo yokubumba.

Ekukhiqizweni kwangempela, kokubili imishini yokubumba ebandayo kanye nemishini yokubumba eshisayo idlala indima ebalulekile.Umshini wokubumba obandayo ulungele izinto ze-alloy ezinezidingo eziphansi zepulasitiki kanye nezidingo zamandla aphezulu.Imvamisa isetshenziselwa ukukhiqiza ama-arganiece asayizi amancane, njenge-bolts, amantongomane, njll. Umshini wokuvuselela oshisayo ulungele izinto zensimbi ezinezidingo eziphakeme ngohlobo lwezinto ezibonakalayo futhi kudingeka uthuthukise ubulukhuni kanye neplastiki.Ingakwazi ukukhiqiza izinto zokusebenza ezinosayizi omkhulu futhi ezinomumo oyinkimbinkimbi, njengama-crankshafts emoto kanye nezingxenye zenjini yomoya.

Ukufingqa, ukucebisisa okubandayo nokuvuselelwa okushisayo kuyizinqubo ezimbili ezivamile ekulweni kwezensimbi.Futhi banokwehluka okuphakeme kokushisa, ipulasitiki yezinto ezibonakalayo, i-microssCreature, kanye nobubanzi bokusebenza.I-Cold forging ifanele izinto ze-alloy ezinamandla aphezulu kanye ne-plasticity ephansi, kuyilapho ukubumba okushisayo kulungele izinhlobo ezihlukahlukene zezinsimbi, ikakhulukazi lezo ezidinga ukuthuthukisa ukuqina kanye ne-plasticity.Imishini ebandayo yokwakha nemishini eshisayo evuthayo imishini ekhethekile esetshenziselwa ukufeza lezi zinqubo ezimbili.Badlala indima ebalulekile emkhakheni we-Metal Processing, enikeza izingxenye zensimbi ezisezingeni eliphakeme ezimbonini ezahlukahlukene.

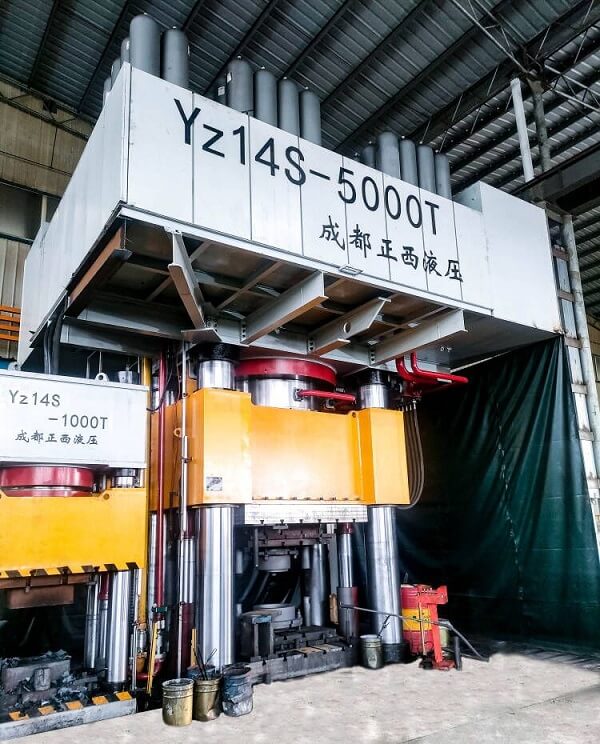

UZhengengxi uyaziwa kahleumkhiqizi wemishini yokunyathelisa e-China, ukuhlinzeka ngemishini esezingeni eliphakeme ebukhoma nemishini eshisayo evuthayo.Uma unezidingo, sicela uxhumane nathi ngokushesha.Ochwepheshe bethu bazokunikeza ngezixazululo eziphelele ze-hydraulic cindezela.

Isikhathi sokuthumela: Aug-04-2023