News

-

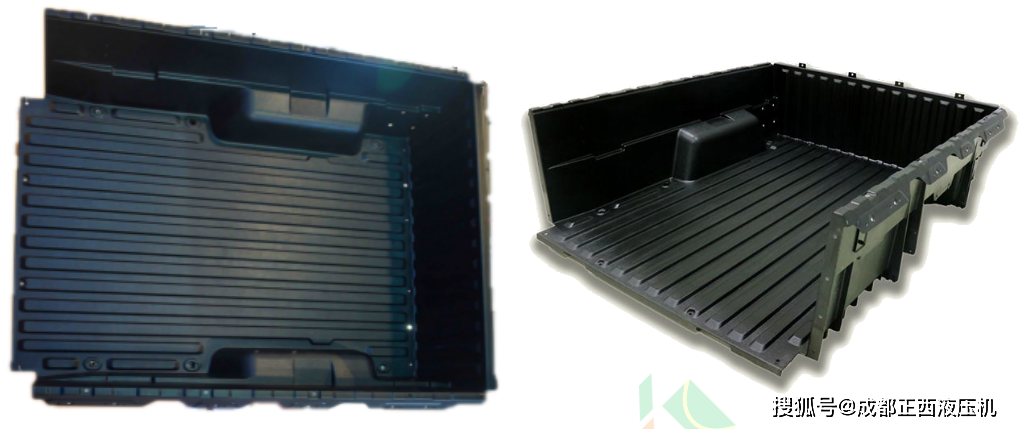

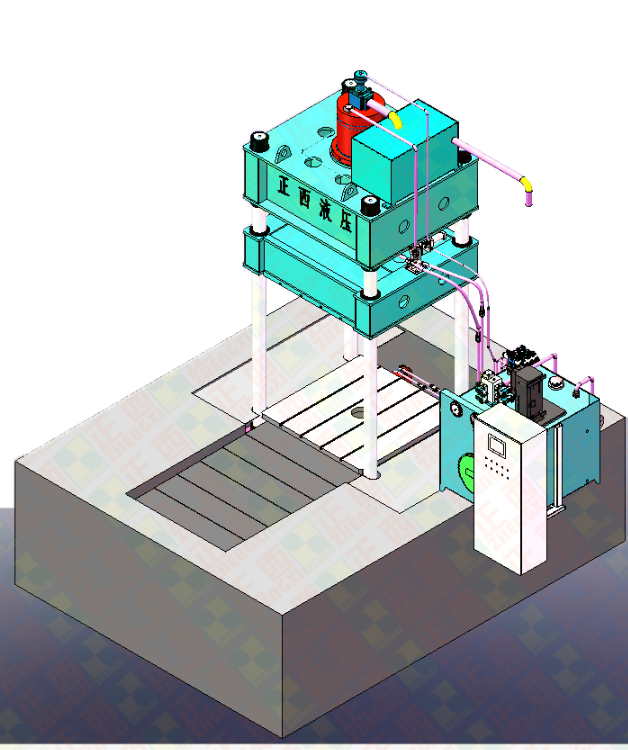

SMC composite material pickup truck back bucket molding case

The auto market has entered a stage of rapid upgrading, and most auto companies are constantly looking for new selling points. Among them, the lightweight of automobiles has become one of the focus of all car companies. Most car companies are focusing on reducing the weight of the skeleton to pro...Read more -

How to adjust the balance of a four-column hydraulic press?

Regarding the adjustment of the parallelism of the hydraulic machine, the parallelism of the slider and the worktable should be adjusted first by adjusting the nut on the upper beam, so that the machine precision adjustment can have a better foundation. Then adjust the equipment to a pressurized ...Read more -

How to operate the four-column hydraulic press to reduce noise

The essential elements of the hydraulic operation process of the three-beam and four-column hydraulic press have been known for a long time: 1. Determine the power loss and temperature rise of the hydraulic system. If the loss is large and the temperature rises, it will affect the normal operatio...Read more -

Servo hydraulic machine precision control and advantages

Ms.Serafina Tel/Wts/Wechat: 008615102806197 Servo hydraulic press is suitable for stretching, bending, flanging, cold extrusion, blanking and other processes of metal materials, and is suitable for correcting press-fitting, pressing of powder products, abrasive products, and press-forming...Read more -

Powder metallurgy compression molding process

Powder metallurgy (Powder metallurgy, referred to as PM) is a metallurgical technology in which metal powder (or a mixture of metal powder and non-metal powder) is used as a raw material to form metal products or materials through forming, sintering or hot forming. The powder metallurgy productio...Read more -

Zhengxi International Powder Metallurgy Exhibition ended perfectly

Powder Metallurgy Cemented Carbide and Advanced Ceramics Exhibition The exhibition attracted a total of more than 600 companies from different regions to participate in the exhibition. The popularity of the scene is high, and the audience is in an endless stream. Zhengxi sales elites have profess...Read more -

ZHENGXI ‖ 2021 China International Powder Metallurgy Cemented Carbide and Advanced Ceramics Exhibition

Meet 2021 China International Powder Metallurgy Cemented Carbide and Advanced Ceramics Exhibition Date: May 23-25, 2021 Address: Shanghai World Expo Exhibition Hall No. 1099, Guozhan Road, Pudong New Area, Shanghai Booth No.: Hall 1, B176 ★ Powder metallurgy technolog...Read more -

BMC Hydraulic press forming process method

BMC is the abbreviation of glass fiber reinforced unsaturated polyester thermosetting plastic, and it is currently the most widely used type of reinforced thermosetting plastic. BMC Features and applications BMC has good physical, electrical and mechanical properties, so it has a wide ran...Read more -

Application status and development direction of FRP/composite materials in automobile industry

As an important lightweight material for automobiles to replace steel with plastic, FRP/composite materials are closely related to automobile energy saving, environmental protection and safety. The use of glass fiber reinforced plastics/composite materials to manufacture automobile body shells a...Read more -

Main considerations for SMC auto parts compression molding machine

1. Equipment tonnage When selecting the molding process of SMC/GRP composite products, the tonnage of the hydraulic press (molding press) can be selected according to the unit pressure that the product bears the least. For eccentric products or products with large depth dimensions where the moldi...Read more -

Problems and solutions that easily occur in the SMC molding process

The problems that are likely to occur in the SMC molding process are: blistering and internal bulging on the surface of the product; warpage and deformation of the product; cracks in the product after a period of time, and partial fiber exposure of the product. The reasons for the related phenome...Read more -

Development of automated manufacturing of advanced composite materials

With the rapid development of advanced composite material technology and process technology, the application proportion of composite materials in aerospace equipment has steadily increased, and the application parts have expanded from non-load-bearing and sub-load-bearing structures to main load-...Read more