News

-

Future development trend of hydraulic press

1. Digital and Intelligent Hydraulic press equipment has been from the initial turret press, folding machine expanded to other categories, category of forging machinery, such as CNC sheet metal linear cutting machine, CNC laser cutting, plasma and flame cutting machine, CNC sheet metal bending...Read more -

Automobile manufacturing and stamping dissoluble affinity

Stamping is a kind of processing with high efficiency, low consumables and low operating technical requirements. Stamping is not only used in large-scale manufacturing but also used in many other aspects (such as watches’ 80% parts are stamping). (The stamping parts that we can see in our life) ...Read more -

Application and advantages of hydraulic press

Hydro forming process has a wide range of applications in automotive, aviation, aerospace and pipeline industries, mainly suitable for: along the axis of the component changes along the circular, rectangular or special-shaped section hollow structural parts, such as automobile exhaust system spec...Read more -

Structure and Classification of Hydraulic press

The drive system of hydraulic press mainly has two types: pump direct drive and pump accumulat drive. The pump direct drive provides high-pressure working fluid tothe hydraulic cylinder, the valve is used to change the direction of the liquid supply, and the relief valve is used to adjust the li...Read more -

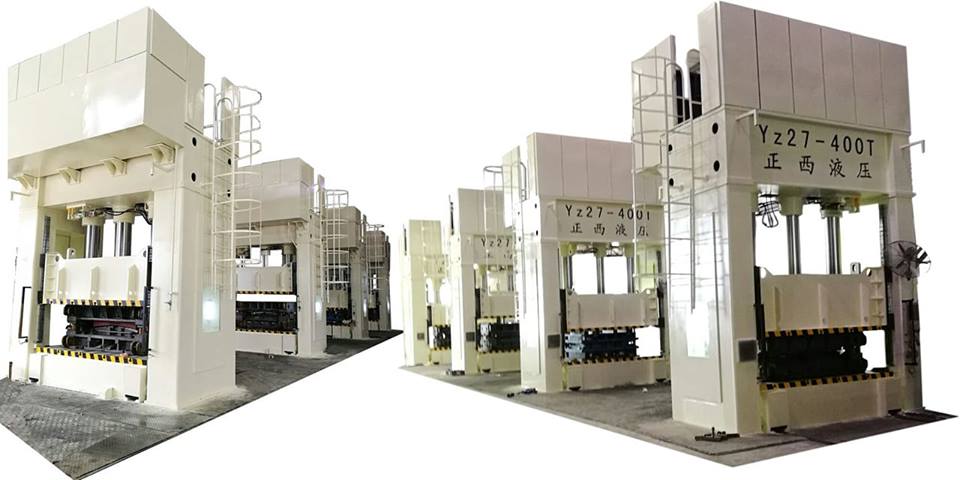

Metal security door forming process

Door embossing machine is a special hydraulic press for forming security doors, steel and wood doors, and indoor doors. It is also suitable for pressing, bending, flanging, extrusion and other processes of plastic materials. It can also be used for calibration, pressing, and powder products. Non-...Read more -

.jpg)

Application fields of powder metallurgy hydraulic press

With the general application of the development of industrial automation, the powder metallurgy products industry has also developed rapidly, and the application fields are no longer limited to the machinery and equipment industry. Nowadays, in places such as supermarkets and supermarkets, the pr...Read more -

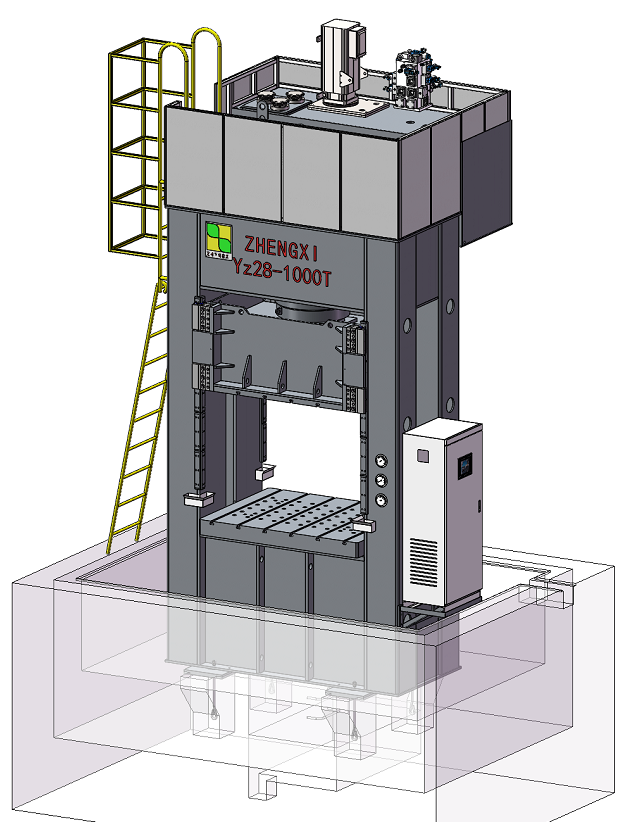

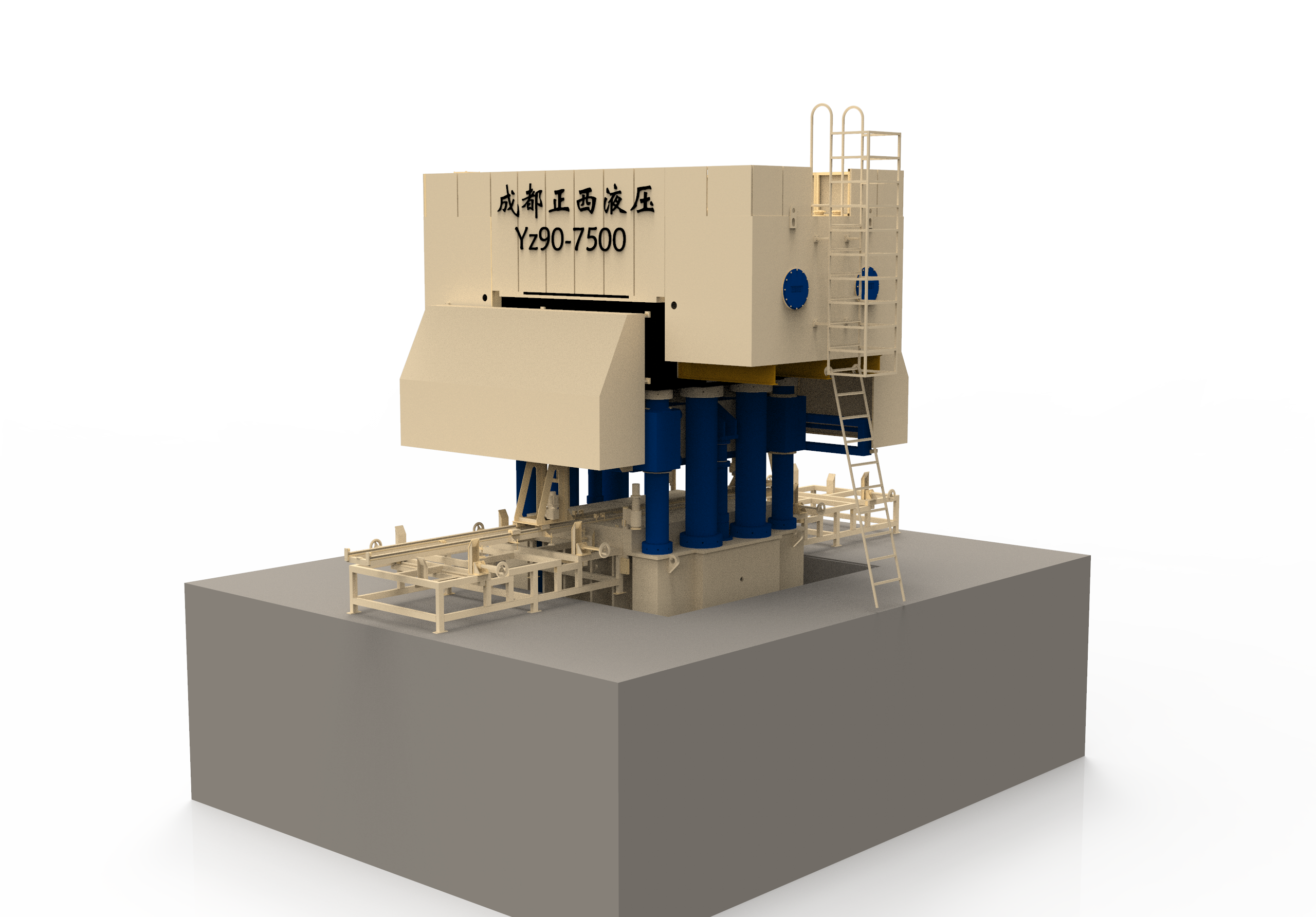

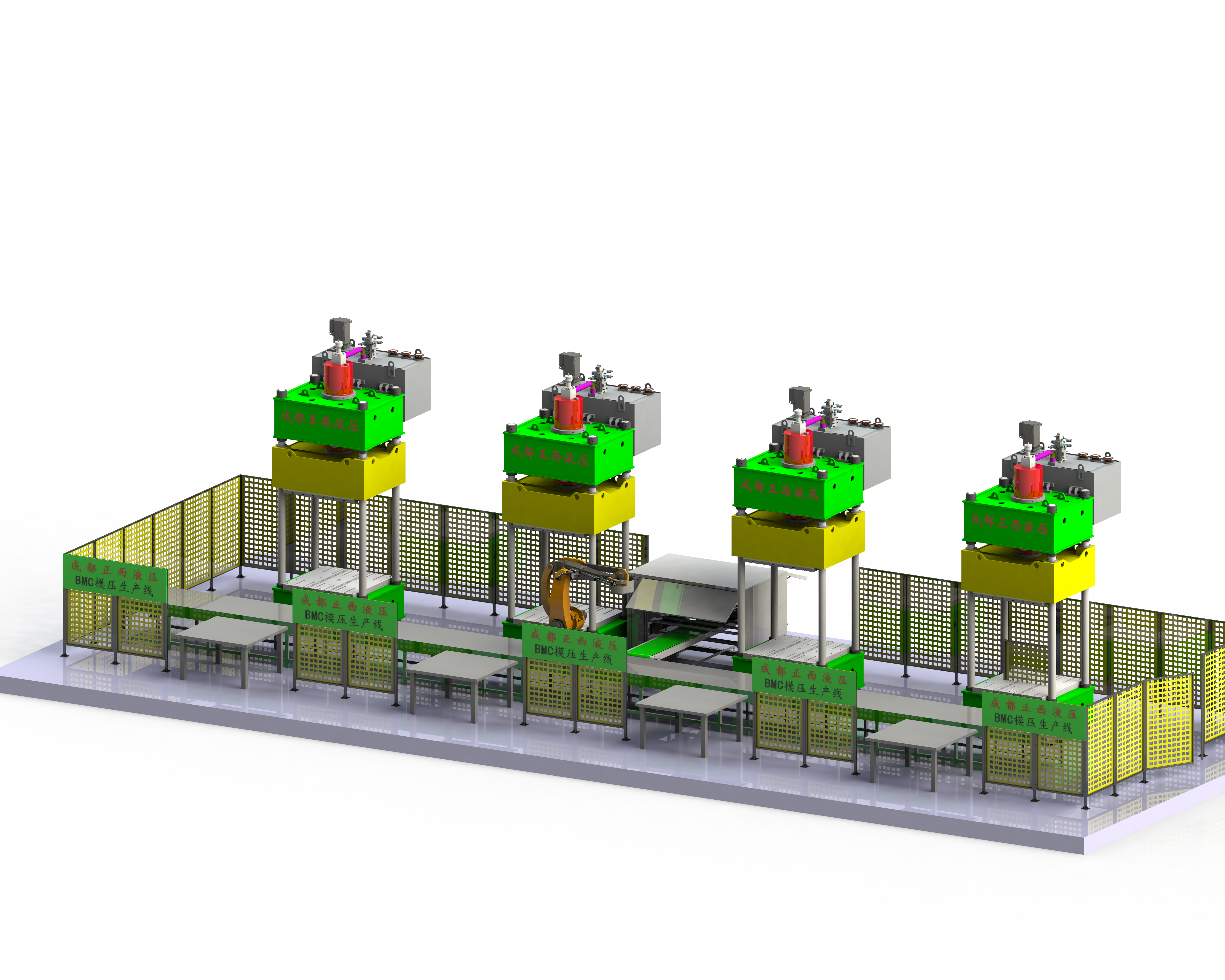

SMC GMT composite material compression molding hydraulic press manufacturer

Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd. specializes in manufacturing SMC molding presses. This series of equipment is also called FRP molding hydraulic presses, suitable for molding SMC, BMC, FRP, GRP, GMT and other composite materials. The parameters of the machine, such as t...Read more -

Application of metal sheet door embossing hydraulic press machine

Door embossing machine is a special hydraulic press for forming anti-theft doors, steel-wood doors, and interior doors. It is also suitable for pressing, bending, flanging, extrusion and other processes of plastic materials. It can also be used for correction, pressing, and pressing and forming o...Read more -

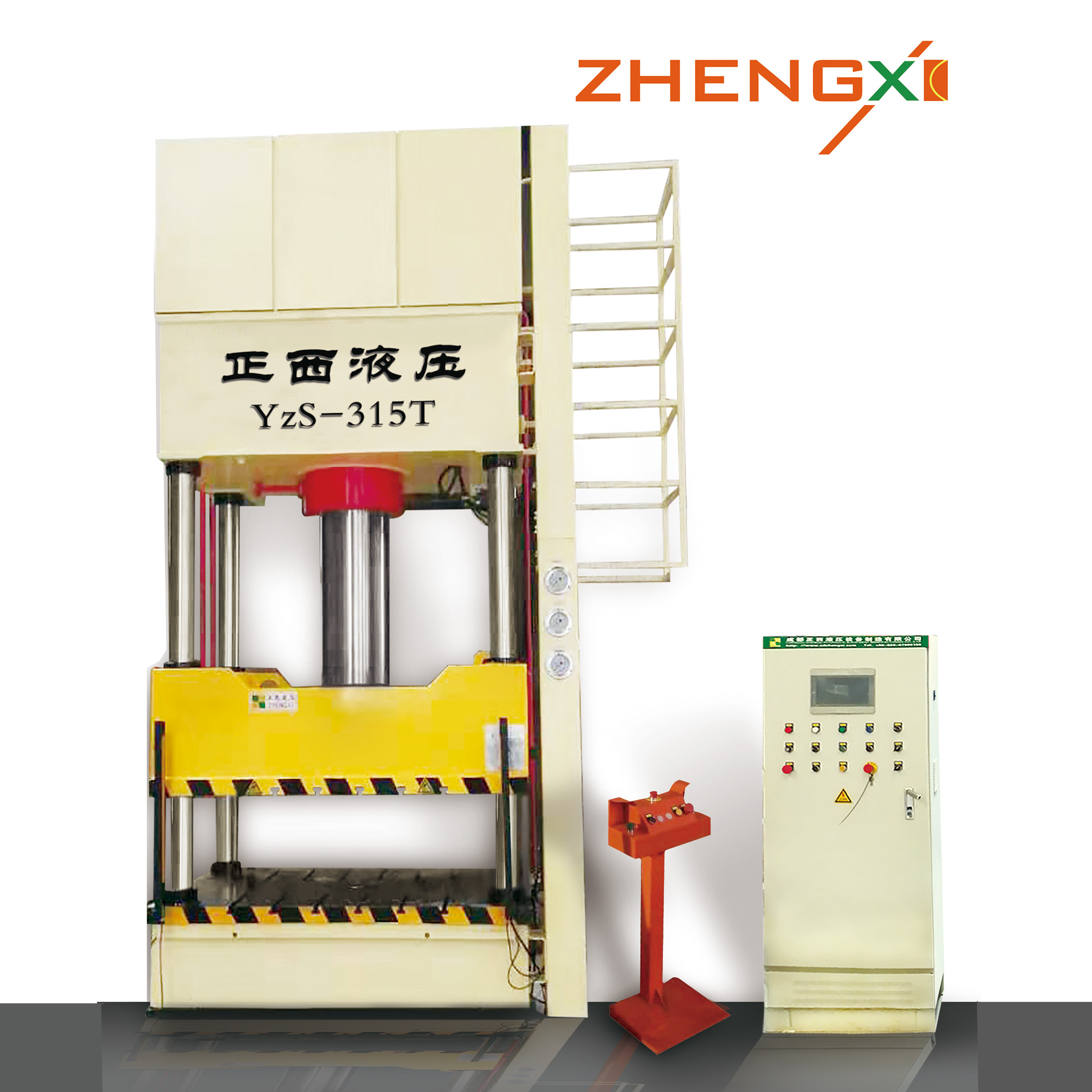

How to make BMC manhole cover? 315T BMC composite resin manhole cover molding hydraulic press

BMC is the abbreviation of Bulk Molding Compound (bulk plastic), which is often called resin glass fiber reinforced plastic in China. Its main raw material is a dough-like prepreg that is fully mixed with GF (chopped glass fiber), UP (unsaturated resin), MD (filler calcium carbonate) and various ...Read more -

2000T of glass fiber reinforced plastic molding machine structure and superiority

FRP compression molding is a method in which a certain amount of prepreg is added to the mold temperature machine to preheat, and the plastic products are cured by heating and pressure. There have many advantages are: 1>high production efficiency, easy to achieve specialized and automated prod...Read more -

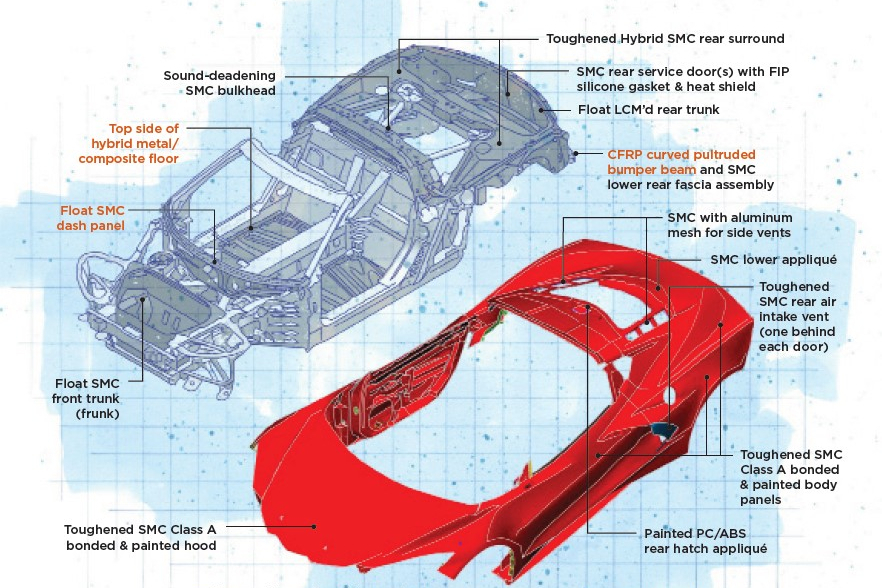

Carbon Fiber Composite Material-Application and Development in Lightweight Transportation

The development of the key basic material industry has an important impact on the implementation of the “Made in China 2025″ strategy. In terms of high-performance fibers, carbon fiber composite materials with the reputation of “black dollar” have gradually become the R...Read more -

Talk on the corrosion resistance of SMC composite materials

SMC is the abbreviation of Sheet molding compound, SMC composite material, SMC molding compound or sheet molding compound (commonly known as FRP material). The main raw materials are composed of SMC special yarn, unsaturated resin, low shrinkage additives, fillers and various additives. SMC has t...Read more