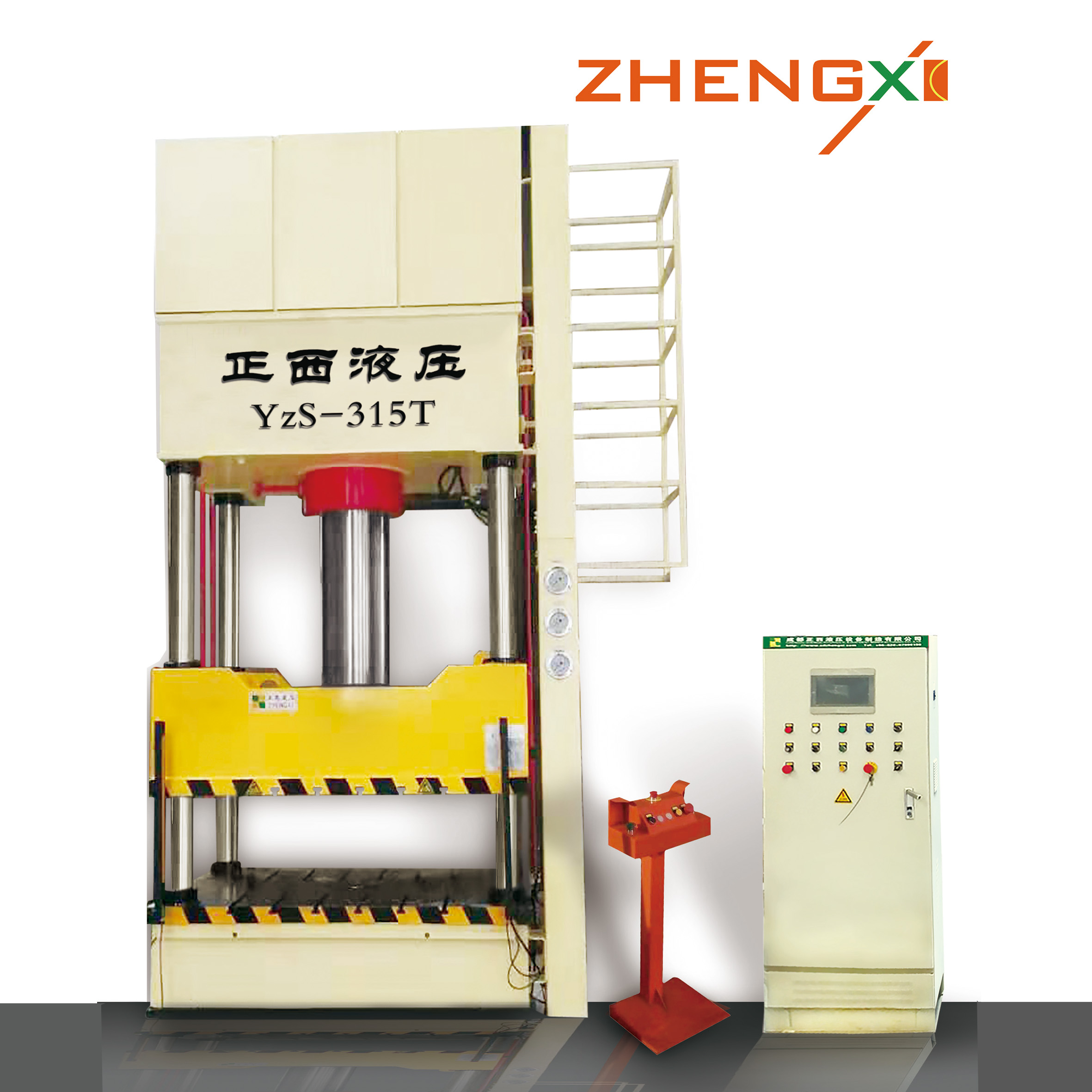

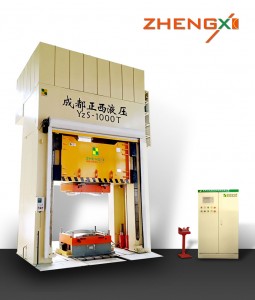

Umatshini wokwenza i-BMC SMC Umngxuma wokwenza isigqubuthelo

I-ZHENGXI SMC BMC Hydraulic Press ikwabizwa ngokuba yi-hydraulic composites molding press, isetyenziswa ekubunjweni koxinzelelo lwezinto ezidibeneyo ezifana ne-SMC, BMC, FRP, GRP njalo njalo.Oomatshini bethu bokwenza i-SMC kunye noshicilelo babonelela ishishini elihlanganisiweyo amandla okuvelisa aphezulu, kunye nokulungisa kunye nokuphucula ukhetho.Sinikezela ngoomatshini bokubumba be-hydraulic amasiko amatsha, kwaye i-ZHENGXI aslo ibonelela ngoluhlu olubanzi lokulungisa kunye nokuphucula okukhethwa kukho koxinzelelo lokubumba olukhoyo kuzo zonke izinto kunye neemodeli.Izishicileli zethu zokubumba i-hydraulic zisetyenziselwa ukuvelisa iindidi ezininzi zeemoto ezintsha, i-aerospace, i-industrial njl.

Iimpawu zoomatshini

Isetyenziswa ikakhulu ukwenza i-integral forming of thermosetting (FRP) iiplastiki kunye neemveliso ze-thermoplastic.Ilungele ukwenziwa kwe-SMC, i-BMC, i-DMC, i-GMT kunye nezinye ii-bulks kunye namaphepha.

I-Hydraulic system ifakwe phezulu kunye neqonga lokulungisa, ihambelana nokusingqongileyo, ingxolo ephantsi kunye nokugcinwa lula.

Ukwenza uxinzelelo lwesantya esicothayo esinamanqanaba amaninzi, ixesha elibekelwe ukukhupha ixesha elifanelekileyo.

Ngomsebenzi woxinzelelo oluphezulu lokuvula okucothayo, okufanelekileyo kwiimveliso eziphezulu.

Ukusabela ngokukhawuleza kwenkqubo, inkqubo yolawulo lwamanani.

KwiSiza Umfanekiso

Usetyenziso

Lo matshini ulungele kakhulu ukubumba izinto ezidibeneyo;isixhobo sinokuqina kwenkqubo elungileyo kunye nokuchaneka okuphezulu, ubomi obuphezulu kunye nokuthembeka okuphezulu.Inkqubo yokwenza i-press eshushu idibana ne-3 shifts / day production.

ImiGangatho yokuVelisa

| JB/T3818-99《Iimeko zobugcisa zoshicilelo lwe-hydraulic》 |

| GB/T 3766-2001《Iimfuno zobugcisa ngokubanzi kwiinkqubo zamanzi》 |

| GB5226.1-2002《Ukhuseleko koomatshini-oomatshini kunye nezixhobo zombane-Icandelo 1: Iimfuno zobugcisa ngokubanzi》 |

| GB17120-97《Cinezela iimfuno zobugcisa zokhuseleko koomatshini》 |

| JB9967-99《Umda wengxolo yomatshini weHydraulic》 |

| JB/T8609-97《Cinezela oomatshini ukuwelda iimeko zobugcisa》 |

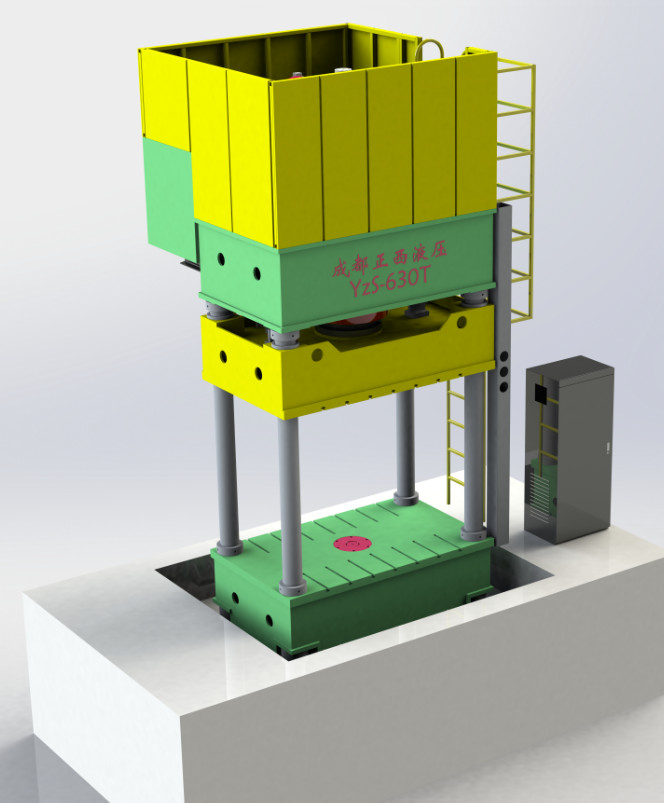

Umzobo we-3D

H uhlobo lwesakhelo

4 uhlobo lwekholamu

Iiparamitha zoomatshini

| Iixesha | Iyunithi | YZ71-4000T | YZ71-3000T | YZ71-2500T | YZ71-2000T | YZ71-1500T | YZ71-1000T |

| Uxinzelelo | kN | 40000 | 30000 | 25000 | 20000 | 15000 | 10000 |

| Max.uxinzelelo lolwelo | Mpa | 25 | 25 | 25 | 25 | 25 | 25 |

| Ukukhanya kwasemini | Mm | 3500 | 3200 | 3000 | 2800 | 2800 | 2600 |

| Istroke | Mm | 3000 | 2600 | 2400 | 2200 | 2200 | 2000 |

| Ubungakanani betafile esebenzayo | Mm | 4000×3000 | 3500×2800 | 3400*2800 | 3400*2600 | 3400*2600 | 3400*2600 |

| Ubude ngaphezu komhlaba | Mm | 12500 | 11800 | 11000 | 9000 | 8000 | 7200 |

| Ubunzulu besiseko | mm | 2200 | 2000 | 1800 | 1600 | 1500 | 1400 |

| Isantya esisezantsi | Mm/s | 300 | 300 | 300 | 300 | 300 | 300 |

| Isantya sokusebenza | Mm/s | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Isantya sokubuya | Mm/s | 150 | 150 | 150 | 150 | 150 | 150 |

| Amandla Aphelele | kW | 175 | 130 | 120 | 100 | 90 | 60 |

UMzimba oPhambili

Uyilo lomatshini wonke lwamkela uyilo lokuphucula ikhompyuter kwaye luhlalutye ngento enomda.Amandla kunye nokuqina kwezixhobo zilungile, kwaye imbonakalo ilungile.Onke amalungu adityanisiweyo omatshini adityaniswe ngentsimbi ekumgangatho ophezulu we-Q345B ipleyiti yentsimbi, edityaniswe ngekhabhoni diokside ukuqinisekisa umgangatho wokuwelda.

Isilinda

| Amacandelo | Findalo |

| Umgqomo wesilinda |

|

| I-Piston Rod |

|

| Amatywina | Yamkela umsesane wokutywina womgangatho we-NOK waseJapan |

| Ipiston | Ukukhokelwa ngokutyalwa kobhedu, ukuchasana kakuhle kokugqoka, ukuqinisekisa ukusebenza kwexesha elide le-cylinder |

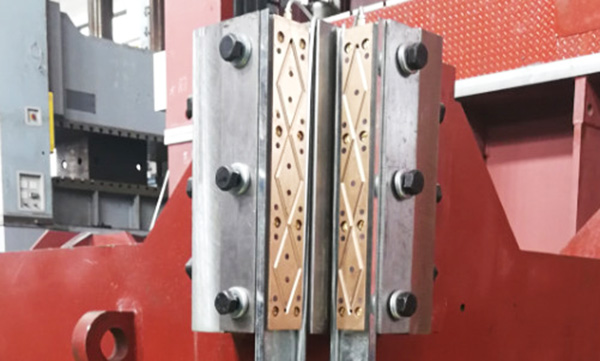

Intsika

Iikholamu zesikhokelo (iintsika) ziya kwenziwaC45 eshushu forging steelkwaye ube nobukhulu obuqinileyo be-chrome obuyi-0.08mm.Kwaye wenze ukuqina kunye nokuthomalalisa unyango.Umkhono wesikhokelo wamkela umkhono wesikhokelo sobhedu, okwaziyo ukunxiba kwaye uphucula ukuzinza komatshini

Inkqubo yeServo

1.Servo System Ukuqulunqwa

2.Servo System Ukuqulunqwa

| Igama | Model | Pumfanekiso | Ainzuzo |

| HMI | Siemens |

| Ubomi beqhosha buvavanywa ngokungqongqo, kwaye awonakali ngokucinezela amaxesha ezigidi ezili-1. Uncedo lwesikrini kunye nempazamo yomatshini, chaza imisebenzi yesikrini, chaza iialam zoomatshini, kwaye uncede abasebenzisi ngokukhawuleza basebenzise umatshini

|

| Igama | Model | Pumfanekiso | Ainzuzo |

| PLC | Siemens |

| Umgca wokufumana irula ye-elektroniki icutshungulwa ngokuzimeleyo, inamandla okumelana nokuphazamiseka Ulawulo lwedijithali lwe-servo drive kunye nokudibanisa kunye nokuqhuba |

| Umqhubi weServo

| YASKAWA |

| I-capacitor ye-busbar iyonke iphuculwe ngokupheleleyo, kwaye i-capacitor enokuguquguquka okubanzi kweqondo lokushisa kunye nobomi benkonzo obude isetyenzisiweyo, kwaye ubomi bethiyori bonyuka ngamaxesha angama-4;

Impendulo kwi-50Mpa yi-50ms, i-pressure overshoot yi-1.5kgf, ixesha lokunciphisa uxinzelelo li-60ms, kunye nokuguquguquka koxinzelelo ngu-0.5kgf.

|

| Iimoto zeServo

| PHASE Series |

| Uyilo lokulinganisa lwenziwa yi-software ye-Ansoft, kwaye ukusebenza kwe-electromagnetic kuphezulu; Ukusebenzisa i-excitation ye-NdFeB ephezulu, ilahleko yentsimbi incinci, ukusebenza kakuhle kuphezulu, kwaye ubushushu buncinci;

|

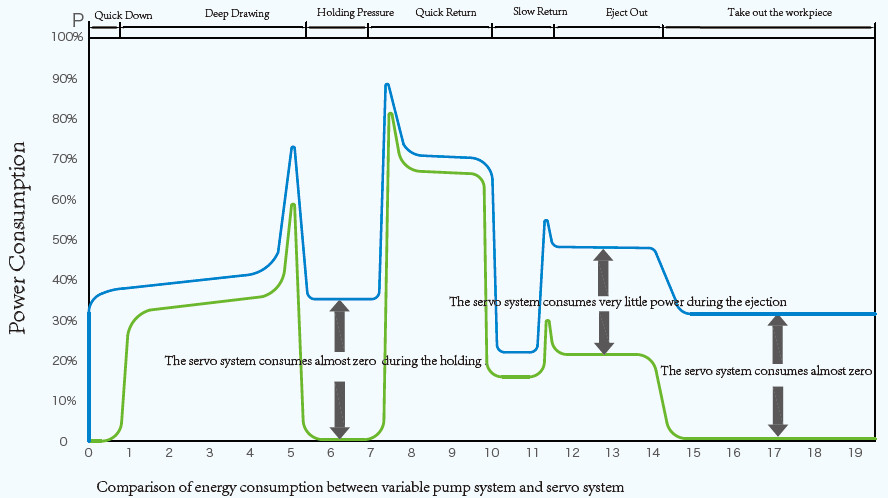

3.Izinto eziluncedo zeServo System

Ukonga amandla

Xa kuthelekiswa nenkqubo yempompo eguquguqukayo yemveli, inkqubo yempompo yeoli ye-servo idibanisa iimpawu zolawulo lwesantya esingena nyathelo se-servo motor kunye neempawu ezizilawulayo zoxinzelelo lweoyile yempompo yeoli ye-hydraulic, ezisa amandla amakhulu okonga, kunye namandla.izinga lokonga lingafikelela kuma-30% -80%.

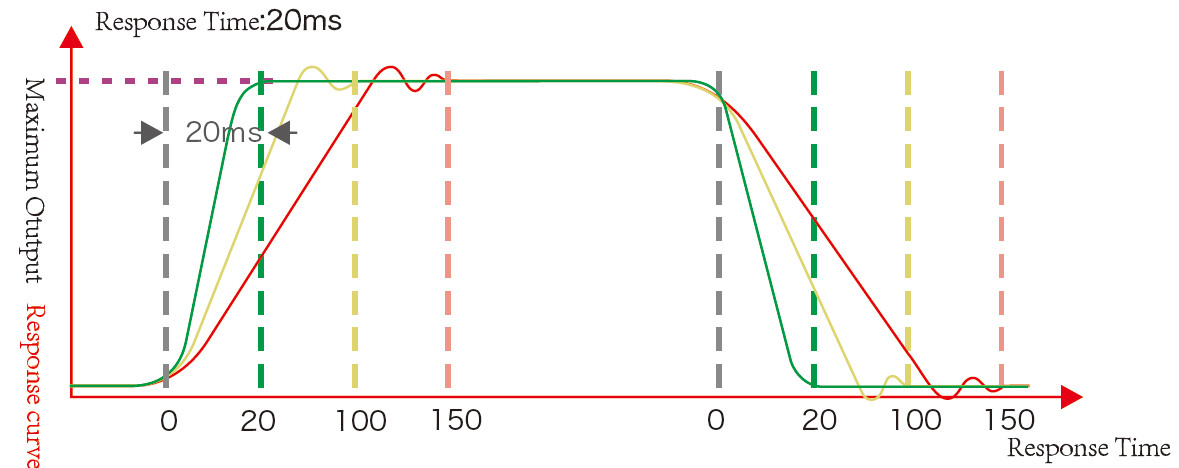

Esebenzayo

Isantya sokuphendula sikhawuleza kwaye ixesha lokuphendula lifutshane njenge-20ms, eliphucula isantya sokuphendula kwenkqubo ye-hydraulic.

Ukuchaneka

Isantya sokuphendula ngokukhawuleza siqinisekisa ukuchaneka kokuvula kunye nokuvala, ukuchaneka kwendawo kunokufikelela kwi-0.1mm, kwaye umsebenzi okhethekileyo wokumisa ukuchaneka unokufikelela.±0.01mm.

Ukuchaneka okuphezulu, impendulo ephezulu yemodyuli ye-algorithm ye-PID iqinisekisa uxinzelelo lwenkqubo ezinzileyo kunye noxinzelelo loxinzelelo olungaphantsi± 0.5 ibha, ukuphucula umgangatho wemveliso.

Ukhuseleko lokusingqongileyo

Ingxolo: Ingxolo eqhelekileyo yenkqubo ye-hydraulic servo yi-15-20 dB ephantsi kunompompo oguquguqukayo wokuqala.

Ubushushu: Emva kokuba inkqubo ye-servo isetyenzisiwe, ukushisa kweoli ye-hydraulic kuncitshiswa ngokubanzi, okwandisa ubomi be-hydraulic seal okanye ukunciphisa amandla opholileyo.

Isixhobo soKhuseleko

Ifoto-yoMbane woKhuseleko loMbane ngaphambili nangasemva

Ukutshixa isilayidi kwi-TDC

Ukuma kokuSebenza kwezandla ezimbini

I-Hydraulic Support Insurance Circuit

Ukukhuselwa komthwalo ogqithisileyo: iValve yoKhuseleko

I-Alarm yeNqanaba lolwelo: Inqanaba le-oyile

Isilumkiso sobushushu be-oyile

Indawo nganye yombane inokhuseleko lokugcwala

Iibhloko zokhuseleko

Amandongomane okutshixa anikezelwe kwiindawo ezishukumayo

Zonke izenzo zoshicilelo zinomsebenzi wokhuseleko onxibelelanayo, umzekelo, itafile eshukumayo ayinakusebenza ngaphandle kokuba umqamelo ubuyela kwindawo yokuqala.Isilayidi asikwazi ukucinezela xa itheyibhile eshukumayo icinezela.Xa kusenzeka ungquzulwano, i-alam ibonisa kwiscreen esichukumisayo kwaye ibonise ukuba yintoni impixano.

Inkqubo yeHydraulic

I-1.Itanki ye-oyile isetiwe ngenkqubo yokucoca ngenkani yokupholisa (isixhobo sokupholisa ipleyiti yeshishini, ukupholisa ngamanzi ajikelezayo, ubushushu be-oyile≤55℃, qiniseka ukuba umatshini unokucofa ngokuthe chu kwiiyure ezingama-24.)

I-2.Inkqubo ye-hydraulic ithatha inkqubo edibeneyo yokulawula i-cartridge valve kunye nesantya sokuphendula ngokukhawuleza kunye nokusebenza kakuhle kokuhanjiswa.

3.Itanki yeoli ixhotyiswe ngesihluzo somoya ukunxibelelana ngaphandle ukuze kuqinisekiswe ukuba ioli ye-hydraulic ayingcoliswa.

I-4.Ukudibanisa phakathi kwe-valve yokuzalisa kunye ne-tank ye-fuel isebenzisa i-flexible joint ukuthintela ukungcangcazela ukuba kungadluliswa kwi-tank ye-fuel kunye nokusombulula ngokupheleleyo ingxaki yokuvuza kweoli.