Adjusting the pressure of a hot press requires careful attention to ensure proper operation and consistent product quality. The specific steps are as follows:

1. Preparation before Commissioning:

First, familiarize yourself with the hot press’s operating manual and understand its rated pressure range, operating principles, and safety precautions. Also, check the hot press’s hydraulic system to ensure the hydraulic oil level is within the specified range and that the oil is clean and free of impurities. Check all hydraulic lines and fittings for secure connections and leaks. Also, check the pressure gauge for proper operation and range.

2. No-load Commissioning:

Before formal pressure adjustment, run the hot press at no-load. Connect the power cord, start the hot press, and run it for a while to observe the machine’s operating status. Ensure that all components are functioning normally and that there are no unusual noises or vibrations. The purpose of this no-load run is to fully warm up the hydraulic system and bring the hydraulic oil to the appropriate operating temperature. This also enables components, such as the hydraulic pump, to function properly.

3. Pressure Setting:

Locate the hot press’s pressure-regulating device. Pressure is typically set by adjusting the relief valve. The relief valve typically has a pressure adjustment knob. Turning this knob changes the system’s pressure setting. When setting pressure, determine the appropriate value based on the hot press’s operating requirements and the material being processed. Start with a low pressure and gradually increase it to avoid initial damage caused by setting too high a pressure.

4. Gradually Increase Pressure for Commissioning:

Slowly turn the pressure adjustment knob to gradually increase the pressure while closely monitoring the pressure gauge reading. Each pressure increase should be minimal; generally, a pressure increase gradient of 0.5-1 MPa is considered. After increasing the pressure, maintain the pressure for a period of time and observe the operation of the hot press, including whether the worktable rises and falls smoothly and whether any components exhibit abnormal deformation or leaks. If any abnormalities are detected during the pressure increase process, immediately stop increasing the pressure, investigate, and resolve the issue before continuing with commissioning.

5. Pressure Testing and Fine-Tuning:

When the pressure approaches the set value, perform a pressure test. Place a simulated workpiece similar to the one being processed on the hot press worktable and perform the hot pressing operation to check whether the pressure is evenly distributed across the workpiece and whether the desired processing result is achieved.

Based on the test results, fine-tune the pressure. If the workpiece is under-pressurized, increase the pressure appropriately. If the workpiece exhibits excessive deformation or damage, reduce the pressure. Fine-tune the pressure settings slowly. Do not adjust the pressure too high at each adjustment.

6. Pressure Calibration:

To ensure that the pressure gauge reading accurately reflects the actual pressure of the heat press, it should be calibrated regularly. Use a standard pressure source for comparison and calibration. If any deviation is detected, adjust or replace the pressure gauge promptly. Furthermore, during commissioning, if the pressure gauge reading is unstable or inaccurate, immediately stop commissioning and inspect the pressure gauge and related pressure sensors for proper function.

7. Post-commissioning Inspection:

After pressure commissioning is complete, re-inspect all components of the heat press to ensure that no new problems have arisen during the commissioning process. Turn off the power to the heat press, clear any debris around the equipment, and keep commissioning records, including the commissioning time, set pressure value, actual pressure value, any problems encountered during commissioning, and their resolutions, for future reference.

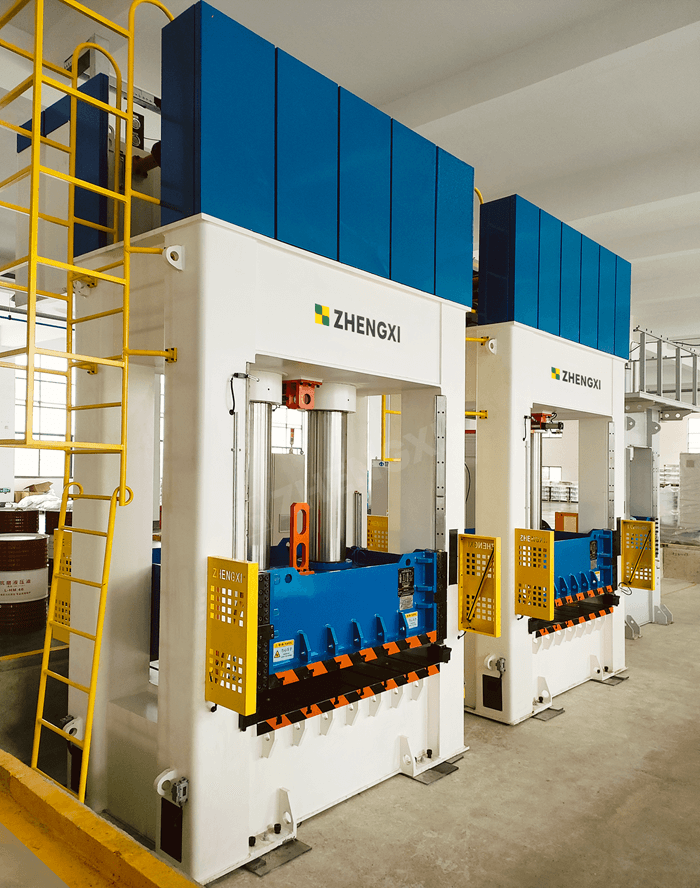

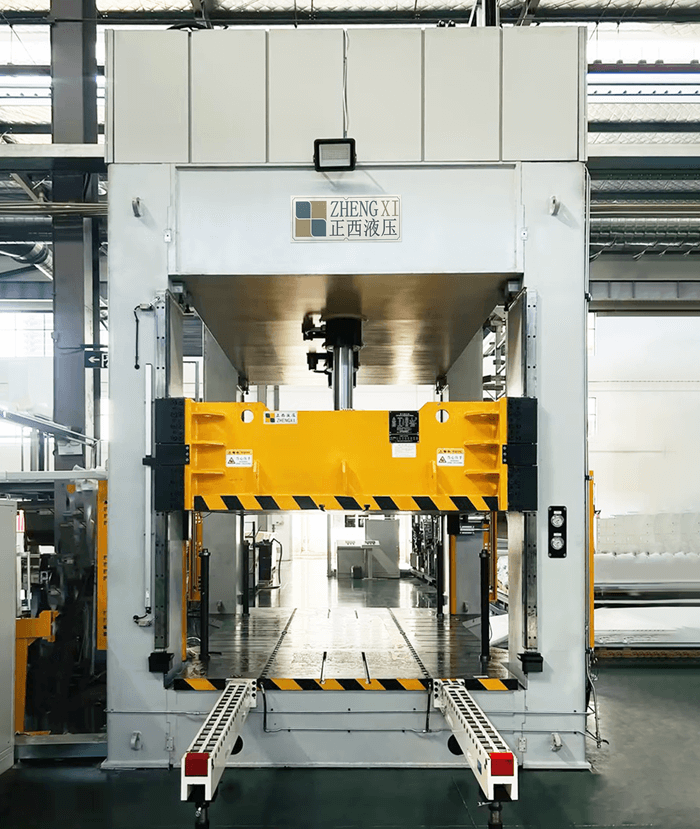

Throughout the commissioning process, be sure to strictly adhere to safety procedures to avoid accidents caused by improper operation. If you are unsure about the pressure commissioning of the hot press or encounter unresolved issues, it is recommended to consult a professional technician or the equipment manufacturer. Chengdu Zhengxi is a specialized hydraulic press manufacturer. If you have any questions, please contact us.

Post time: Sep-08-2025