News

-

The Role of Composite Hydraulic Presses in the Forming of Carbon Fiber Products

Composite hydraulic presses play a very important role in forming carbon fiber products. Carbon fiber consists of carbon fiber bundles (filament or chopped strands) and a resin matrix. In order for the carbon fibers to better bond with the resin and form the desired shape, a pressing and curing p...Read more -

What is a Servo Hydraulic Press

The servo hydraulic press is an energy-saving and high-efficiency hydraulic press that uses a servo motor to drive the main transmission oil pump, reduces the control valve circuit, and controls the slider of the hydraulic press. It is suitable for stamping, die forging, pressing, straightening, ...Read more -

Application of BMC and SMC Materials

BMC/DMC material is the English abbreviation of Bulk molding compound/Dough molding compound. Its main raw materials are chopped glass fiber (GF), unsaturated polyester resin (UP), filler (MD), and a mass prepreg made of fully mixed additives. It is one of the thermosetting molding materials. BMC...Read more -

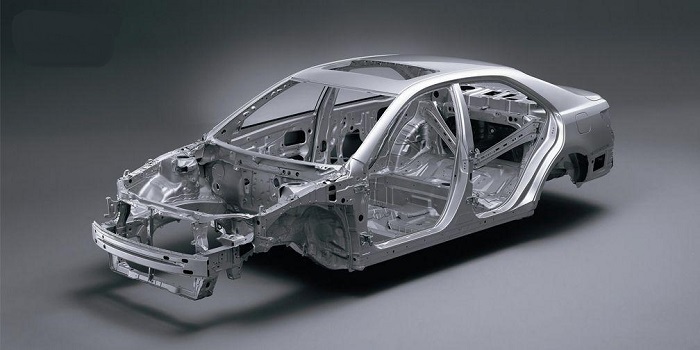

Stamping Process in Automobile Manufacturing

Cars have been called “machines that changed the world.” Because the automobile industry has a strong industrial correlation, it is regarded as an important symbol of a country’s economic development level. There are four major processes in automobiles, and the stamping process ...Read more -

Commonly Used Forging Methods and Their Advantages and Disadvantages

1. Free forging Free forging refers to the processing method of using simple general-purpose tools or directly applying an external force to the blank between the upper and lower anvils of the forging equipment to deform the blank to obtain forgings with the required geometric shape and in...Read more -

How to Choose SMC Molding Machine

SMC hydraulic presses are mainly used to manufacture high-strength titanium/aluminum alloy forgings in the fields of aviation, aerospace, nuclear power, petrochemical, and other fields. At the same time, it is also used in automotive lightweight (fenders, panels, trunks, interior parts, etc.) and...Read more -

Fault Diagnosis Method of Hydraulic Equipment

There are many methods for diagnosing hydraulic equipment failures. At present, the commonly used methods are visual inspection, comparison and replacement, logical analysis, special instrument detection, and state monitoring. Table of Content: 1. Visual Inspection Method 2. Comparison and Substi...Read more -

Ultimate Guide of CFRP: Carbon Fiber Reinforced Plastic/Polymer

With the continuous development of composite materials, in addition to glass fiber-reinforced plastics, carbon fiber-reinforced plastics, boron fiber-reinforced plastics, etc. have appeared. Carbon fiber reinforced polymer composites (CFRP) are lightweight and strong materials that are used to ma...Read more -

Composition and Application of Sheet Molding Compound

Sheet molding compound refers to unsaturated polyester resin as the main body, adding curing agent, mold release agent, filler, low shrinkage agent, thickener, etc. Molding compound covered with polyethylene (PE) film. This paper mainly briefly describes the composition and classification applica...Read more -

7 Rubber Molding Processes

There are various processes for rubber molding. This article mainly introduces 7 commonly used methods, analyzes their advantages and applications, and helps you better understand rubber molding. 1. Injection Molding Rubber injection molding is also called injection molding. It is a production ...Read more -

10 Commonly Used Plastic Molding Processes

Here we will introduce 10 commonly used plastic molding processes. Read to know more details. 1. Injection Molding 2. Blow Molding 3. Extrusion Molding 4. Calendering (sheet, film) 5. Compression Molding 6. Compression Injection Molding 7. Rotational Molding 8. Eight, Plastic Drop Molding 9. Blis...Read more -

Deep Drawing Forming Process Practical Application

Metal deep drawing is the process of stamping metal sheets into hollow cylinders. Deep drawing is used in a wide range of production processes, such as in the production of car parts, as well as household products, such as stainless steel kitchen sinks. Process cost: mold cost (extremely high),...Read more