Mechanical Forging Presses

Zhengxi yog tus kws tshaj lijmanufacturers ntawm hydraulic presses nyob rau hauv Suav teb, thiab tus tsim thiab tsim cov tshuab zoo tshaj plaws forging tshuab.

Lub tshuab xovxwm hloov pauv lub zog sib hloov ntawm lub cev muaj zog rau hauv kev txhais lus quab yuam vector uas ua haujlwm nias.Yog li ntawd, lub zog hauv lub tshuab xovxwm tshuab los ntawm lub cev muaj zog.Cov hom xovxwm no feem ntau nrawm dua li hydraulic lossis ntsia hlau nias.Zhengxi's mechanical forging presses muab cov qib siab tshaj plaws ntawm kev ua haujlwm hauv cov cheeb tsam hauv qab no: sov forging (qhov kub ntawm 550 txog 950 ° C) thiab kub forging (qhov kub ntawm 950 txog 1,200 ° C)

Tsis zoo li qee cov xovxwm, nyob rau hauv ib tug neeg kho tshuab xovxwm, qhov ceev thiab qhov loj ntawm cov ntaub ntawv thov sib txawv nyob rau hauv lub stroke nrug.Qhov tseeb ntawm kev mus ncig yog qhov tseem ceeb thaum ua haujlwm tsim khoom nrog cov tshuab presses.

Cov tshuab xovxwm tshuab feem ntau yog siv rau hauv cov hlau forging fabrication thiab sheet hlau fabrication.Daim ntawv thov quab yuam yuav tsum txiav txim siab txog hom tshuab xav tau.Squeezing feem ntau yuav tsum tau muaj zog sib xws nyob rau hauv kev ncua ntev.

Mechanical presses feem ntau yog ib qho kev xaiv zoo rau kev cuam tshuam extrusion.Vim hais tias qhov kev thov ceev thiab rov ua dua ntawm kev quab yuam dhau ib qho kev ncua deb yog xav tau rau hom kev tsim khoom no.Lub tshuab muaj zog tshaj plaws forging presses hauv kev tsim khoom niaj hnub muaj peev xwm ntawm kwv yees li 12,000 tons (24,000,000 lbs).

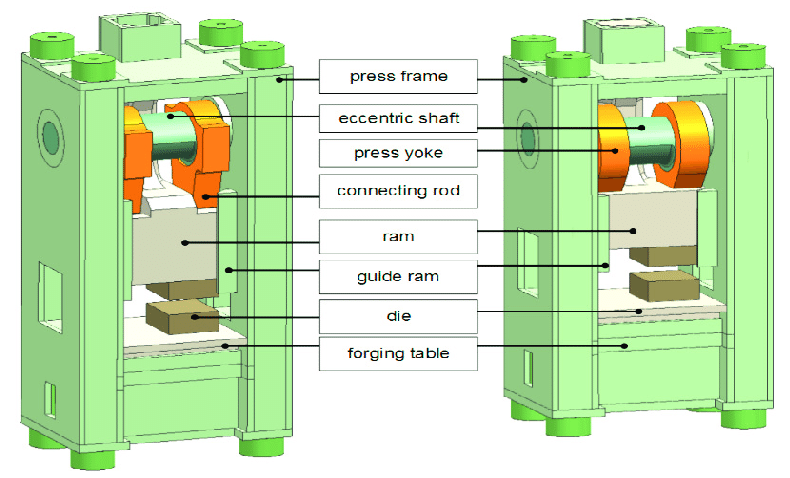

Txoj Cai Ua Haujlwm

Mechanical forging presses yog powered los ntawm ib tug motorized flywheel.Lub flywheel hloov lub zog mus rau lub piston.Lub piston maj mam siv lub siab rau cov pwm.

Lub tshuab yog yuam los ntawm lub cev muaj zog thiab tswj los ntawm huab cua clutch.Thaum lub sij hawm stroke, lub crankshaft ntawm cov xovxwm siv tas li, ib txwm siab rau lub punch.Qhov no zoo ib yam li cov duab nias av nplaum rau hauv xib-teg ntawm koj txhais tes.Ceev tsis sib npaug zog.Cov xovxwm yuav ceev tshaj plaws nyob rau hauv nruab nrab ntawm cov hlab ntsha ua ntej qhov ntom ntawm cov hlau yog compressed heev.Nws tsis ncav cuag qhov siab tshaj plaws kom txog rau thaum kawg ntawm kev mob stroke, nias lub workpiece mus rau hauv nws cov duab kawg.

Txij li thaum cov neeg kho tshuab thawb pas nrig txav mus rau qhov chaw ruaj khov, thaum koj siv lub xovxwm kom paub tseeb tias qhov kev kaw ntawm qhov kawg ntawm cov hlab ntsha tsis me dhau, yog li lub laub pas nrig tsis lo rau qhov tuag hauv qab ntawm nws cov hlab ntsha.

Nta ntawm Mechanical Forging Xovxwm

- Ntau yam ntawm qhov chaw thiab cov khoom tsim tau siab.

- Siv nominal pressures los ntawm 2,500 kN txog 20,000 kN, qhov dav tshaj plaws ntawm cov geometries tuaj yeem tsim tau siv ob qho tib si sov thiab kub forging.

- Advanced tsav kinematics thiab kev ua tau zoo ntawm lub txaj txaj thiab swb-sab ejectors muab cov xwm txheej zoo rau kev txhim kho qhov chaw tuav thiab ua haujlwm siab.

- Qhov zoo tshaj qhov zoo thiab cov cuab yeej siv lub neej ntev.

- Lub tshuab forging xovxwm thav duab yog qhov zoo heev welded tsim.

- Nws cov compact tsim thiab 2-point zawv zawg ncua kev kawm ntawv cia siab nruj thiab siab eccentric loads.

- Cov lus qhia slider heev heev.

- Qhov chaw pwm dav dav muab chav txaus los sib xyaw ua ke ntau qhov chaw ua haujlwm pwm nrog 5-6 qhov chaw tsim khoom.Xws li ib tug loj tus naj npawb ntawm forming chaw enables ntau meej txoj kev geometries.

- Txawm tias qhov nqaim ntawm qhov kam rau ua tuaj yeem ua tiav nrog kev xaiv sizing / calibration ua haujlwm.

- Tsawg txij nkawm thiab siv tau yooj yim.Tus tsim, tua, thiab tswj software ntawm Zhengxi xovxwm series yog heev neeg siv-phooj ywg.Qhov no ua kom lub sijhawm pib thiab hloov pauv luv luv nrog rau kev pabcuam tsawg dua thiab sijhawm kho.

Peb Mechanical Forging Presses Advantages

- High tso zis tus nqi

- Qhov zoo tshaj plaws

- Ntau yam ntawm qhov chaw

- Ntev stroke ntev

- Tsawg kawg lub sij hawm sib cuag

- Ntxiv lub sijhawm tsis sib cuag rau qhov txias txias

- Lub neej ntev

- Loj tuag qhov chaw

- Tight tivthaiv tolerances thiab siab tivthaiv zoo

- Optional servo tsav

Daim ntawv thov ntawm Mechanical Forging Xovxwm

Vim tus nqi siab, mechanical forging presses tsuas yog tsim nyog rau cov ntawv thov ntim siab.Piv txwv li, lawv tau siv dav hauv kev lag luam tsheb los tsim thiab pwm tsav tsheb qhov chaw.Tsoom fwv kuj siv lawv rau nyiaj npib.