News

-

.jpg)

Application fields of powder metallurgy hydraulic press

With the general application of the development of industrial automation, the powder metallurgy products industry has also developed rapidly, and the application fields are no longer limited to the machinery and equipment industry. Nowadays, in places such as supermarkets and supermarkets, the pr...Read more -

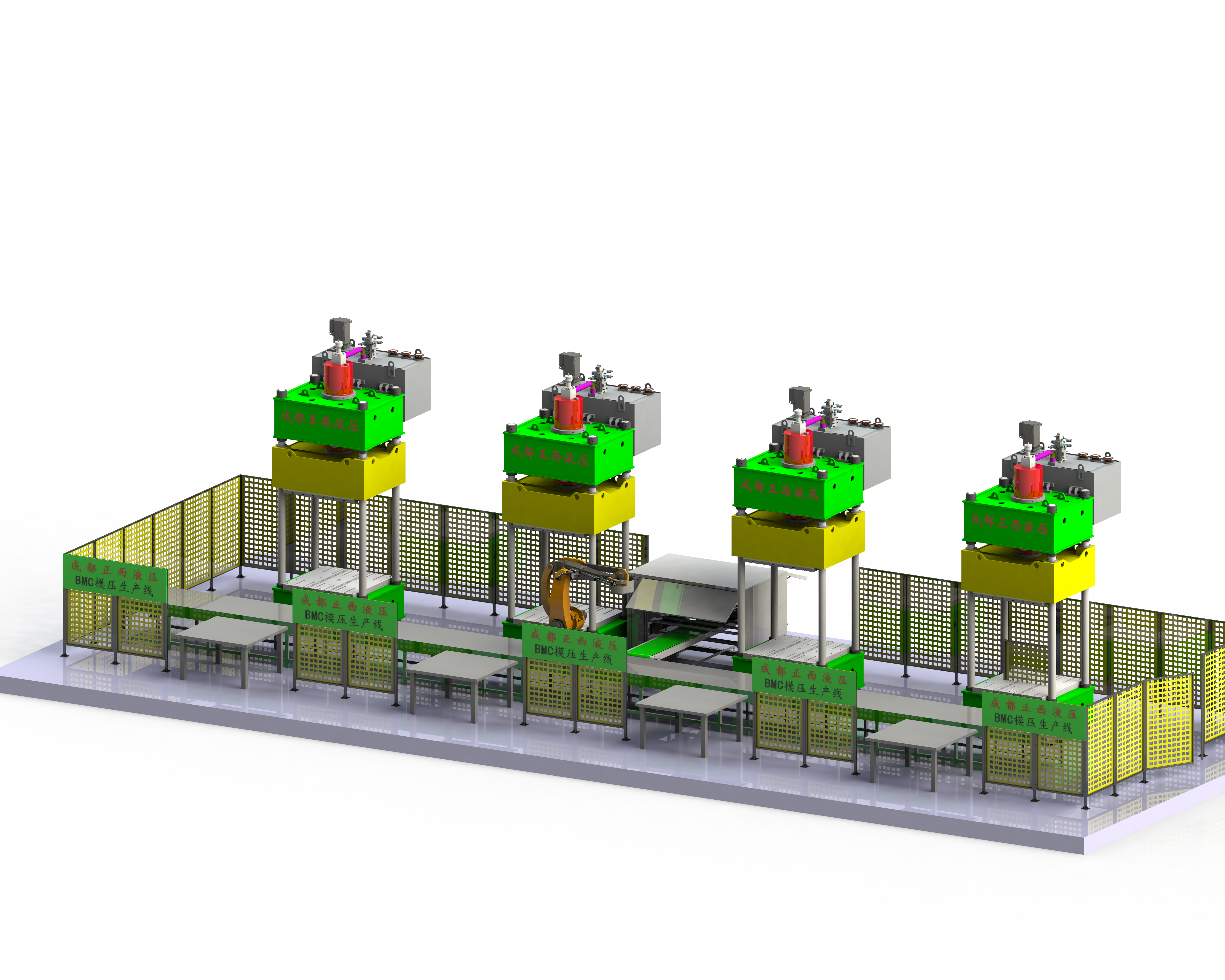

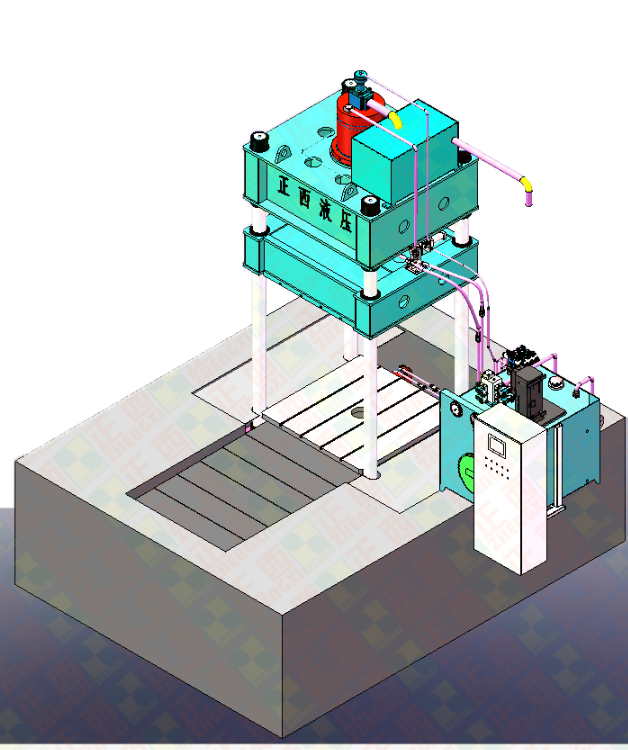

SMC GMT composite material compression molding hydraulic press manufacturer

Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd. specializes in manufacturing SMC molding presses. This series of equipment is also called FRP molding hydraulic presses, suitable for molding SMC, BMC, FRP, GRP, GMT and other composite materials. The parameters of the machine, such as t...Read more -

Application of metal sheet door embossing hydraulic press machine

Door embossing machine is a special hydraulic press for forming anti-theft doors, steel-wood doors, and interior doors. It is also suitable for pressing, bending, flanging, extrusion and other processes of plastic materials. It can also be used for correction, pressing, and pressing and forming o...Read more -

How to make BMC manhole cover? 315T BMC composite resin manhole cover molding hydraulic press

BMC is the abbreviation of Bulk Molding Compound (bulk plastic), which is often called resin glass fiber reinforced plastic in China. Its main raw material is a dough-like prepreg that is fully mixed with GF (chopped glass fiber), UP (unsaturated resin), MD (filler calcium carbonate) and various ...Read more -

2000T of glass fiber reinforced plastic molding machine structure and superiority

FRP compression molding is a method in which a certain amount of prepreg is added to the mold temperature machine to preheat, and the plastic products are cured by heating and pressure. There have many advantages are: 1>high production efficiency, easy to achieve specialized and automated prod...Read more -

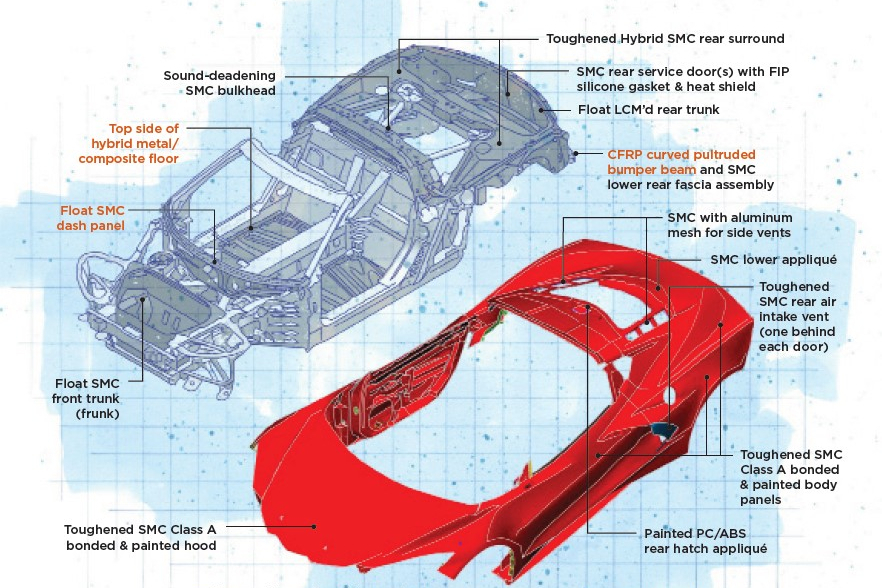

Carbon Fiber Composite Material-Application and Development in Lightweight Transportation

The development of the key basic material industry has an important impact on the implementation of the “Made in China 2025″ strategy. In terms of high-performance fibers, carbon fiber composite materials with the reputation of “black dollar” have gradually become the R...Read more -

Talk on the corrosion resistance of SMC composite materials

SMC is the abbreviation of Sheet molding compound, SMC composite material, SMC molding compound or sheet molding compound (commonly known as FRP material). The main raw materials are composed of SMC special yarn, unsaturated resin, low shrinkage additives, fillers and various additives. SMC has t...Read more -

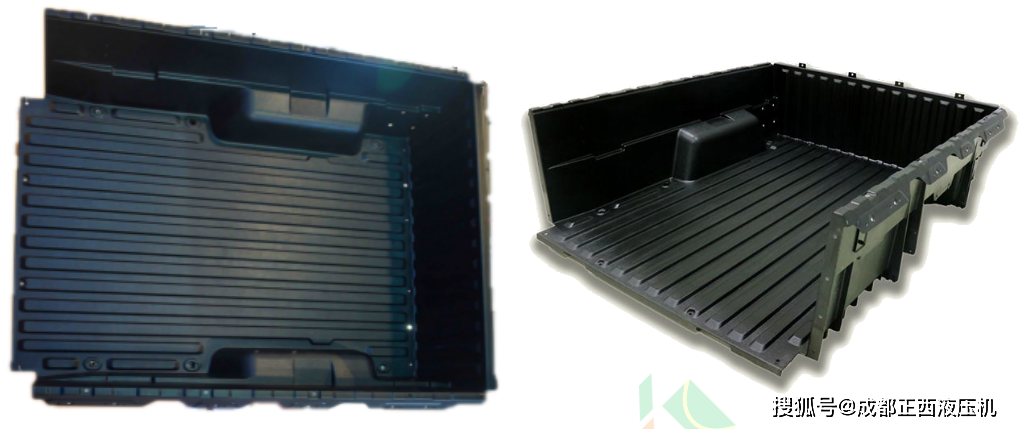

SMC composite material pickup truck back bucket molding case

The auto market has entered a stage of rapid upgrading, and most auto companies are constantly looking for new selling points. Among them, the lightweight of automobiles has become one of the focus of all car companies. Most car companies are focusing on reducing the weight of the skeleton to pro...Read more -

How to adjust the balance of a four-column hydraulic press?

Regarding the adjustment of the parallelism of the hydraulic machine, the parallelism of the slider and the worktable should be adjusted first by adjusting the nut on the upper beam, so that the machine precision adjustment can have a better foundation. Then adjust the equipment to a pressurized ...Read more -

How to operate the four-column hydraulic press to reduce noise

The essential elements of the hydraulic operation process of the three-beam and four-column hydraulic press have been known for a long time: 1. Determine the power loss and temperature rise of the hydraulic system. If the loss is large and the temperature rises, it will affect the normal operatio...Read more -

Servo hydraulic machine precision control and advantages

Ms.Serafina Tel/Wts/Wechat: 008615102806197 Servo hydraulic press is suitable for stretching, bending, flanging, cold extrusion, blanking and other processes of metal materials, and is suitable for correcting press-fitting, pressing of powder products, abrasive products, and press-forming...Read more -

Powder metallurgy compression molding process

Powder metallurgy (Powder metallurgy, referred to as PM) is a metallurgical technology in which metal powder (or a mixture of metal powder and non-metal powder) is used as a raw material to form metal products or materials through forming, sintering or hot forming. The powder metallurgy productio...Read more