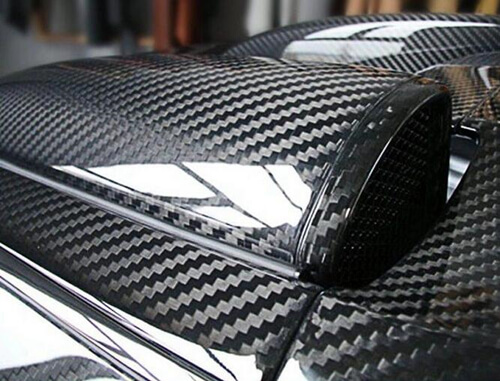

Carbon fiber products are now widely used in aerospace, sports equipment, automobile manufacturing, medical equipment, and other fields. This product has the application advantages of high strength, high stiffness, high fracture toughness, corrosion resistance, and strong designability. The four-column hydraulic press has high stability, adjustable temperature, pressure, and time, and is suitable for processing various carbon fiber products.

Why use a four-column hydraulic press to mold carbon fiber?

1. The three-beam and four-column hydraulic press is welded with steel plates, with good rigidity and high strength. Equipped with master cylinder and top cylinder. The working pressure and working stroke can be adjusted according to the needs within a certain range.

2. The heating element adopts an infrared radiation heating tube. Fast response, high efficiency, and energy saving. Preheating and holding times can be preset according to the different requirements of the product.

3. The molding power adopts a special gas-liquid booster cylinder. Its characteristics are fast and smooth. It can complete the forming working stroke of 250mm within 0.8 seconds. Guarantee the quality and production efficiency of molded products.

4. Temperature control. The temperature of the upper and lower heating templates is controlled separately. An imported intelligent temperature controller is adopted, with an accurate temperature difference of ±1°C.

5. Low noise. The hydraulic part adopts imported high-performance control valves. Low oil temperature, low noise, safe and stable performance.

6. Easy process adjustment. The pressure, stroke, speed, holding time, and closing height can be adjusted arbitrarily according to the production process. Easy to operate.

Advantages of four-column hydraulic press

The four-column hydraulic press has many advantages such as high speed and high efficiency, energy saving and environmental protection, good flexibility, fast response, high load rigidity, and large control power. It is widely used in stamping, die forging, pressing, straightening, molding, and other processes. This machine is mainly used for the molding and pressing process of carbon fiber, FRP, SMC, and other molding materials. Meet the requirements of the pressing process. Equipment temperature, curing time, pressure, and speed are all in line with the process characteristics of SMC/BMC materials. Adopt PLC control, easy to operate, adjustable working parameters.

The 5 deformation processes of four-column hydraulic press molding carbon fiber products are as follows:

1. The mold is heated up within a certain period of time to melt the resin in the carbon fiber cloth in the mold.

2. Control the mold temperature within a certain temperature so that the resin can fully circulate in the mold.

3. The temperature of the mold is raised to a higher temperature, so that the catalyst in the prepreg, that is, the carbon fiber prepreg, reacts.

4. High-temperature insulation. In this process, the resin fully reacts with the catalyst in the carbon fiber prepreg.

5. Cooling forming. This is a preliminary shape of carbon fiber products.

In the 5 deformation processes of compression molding, the control of mold temperature must be precise. And it must be carried out according to a certain heating and cooling rate. Too fast or too slow heating and cooling speeds will affect the final quality of carbon fiber products.

The carbon fiber forming presses designed and manufactured by Chengdu Zhengxi Hydraulics include four-column hydraulic presses and H-frame hydraulic presses. The four-column hydraulic press is simple in structure, economical and practical, and easy to operate. The frame hydraulic press has higher rigidity and strength, and strong anti-eccentric load capacity, and the price is slightly higher than that of the four-column hydraulic press. Both models can be customized according to the needs of carbon fiber products, such as the working table, opening height, cylinder stroke, working speed, and other technical parameters of the hydraulic press. The price of a carbon fiber hydraulic press is determined according to the model, tonnage, and technical parameters. Contact us for more information.

Post time: Sep-09-2023