Ngophuhliso oluqhubekayo lwezinto ezidibeneyo, ngaphezu kweeplastiki ze-glass fiber-reinforced, i-carbon fiber-reinforced plastics, i-boron fiber-reinforced plastics, njl.I-carbon fiber yalungisa i-polymerI-PFRASE (i-CFRP) iphosakele kunye nezinto ezinamandla ezisetyenziselwa ukwenza iimveliso ezininzi esizisebenzisa kubomi bethu bemihla ngemihla.Ligama elisetyenziselwa ukuchaza izixhobo zokudibanisa izinto eziqingqiweyo ezisebenzisa i-carbon fibers njengeyona nto iphambili yolwakhiwo.

Isiqulatho:

1. ISakhiwo sePolymer eFayibha yeCarbon

2. Indlela yokubumba ye-carbon fiber eqinileyo

3. Iipropathi ze-carbon fiber yomeleza i-polymer

4. Izinto eziluncedo zeCFRP

5. Izinto ezingeloncedo kwiCFRP

6. ICarbon Fiber Eyongeziweyo yokusetyenziswa kwePlastiki

I-Carbon Fiber eQiniswayo neSakhiwo sePolymer

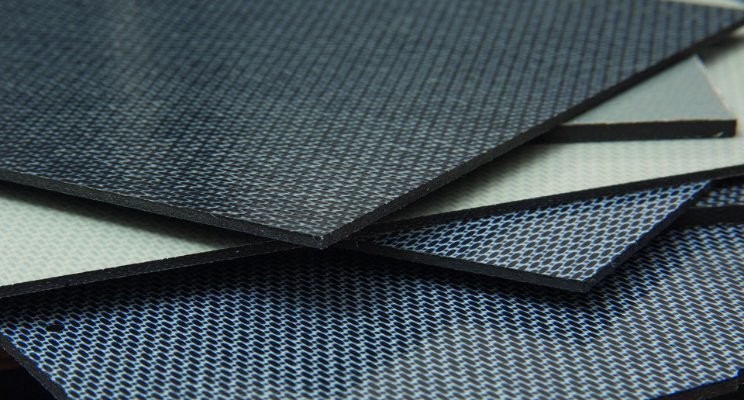

Iplastiki yeCarbon fibre eyomeleziweyo yinto eyenziwe ngokucwangcisa imathiriyeli yefayibha yekhabhoni kwicala elithile kunye nokusebenzisa izixhobo zepolymer ezibotshiweyo.Idayamitha ye-carbon fiber incinci kakhulu, malunga ne-7 microns, kodwa amandla ayo aphezulu kakhulu.

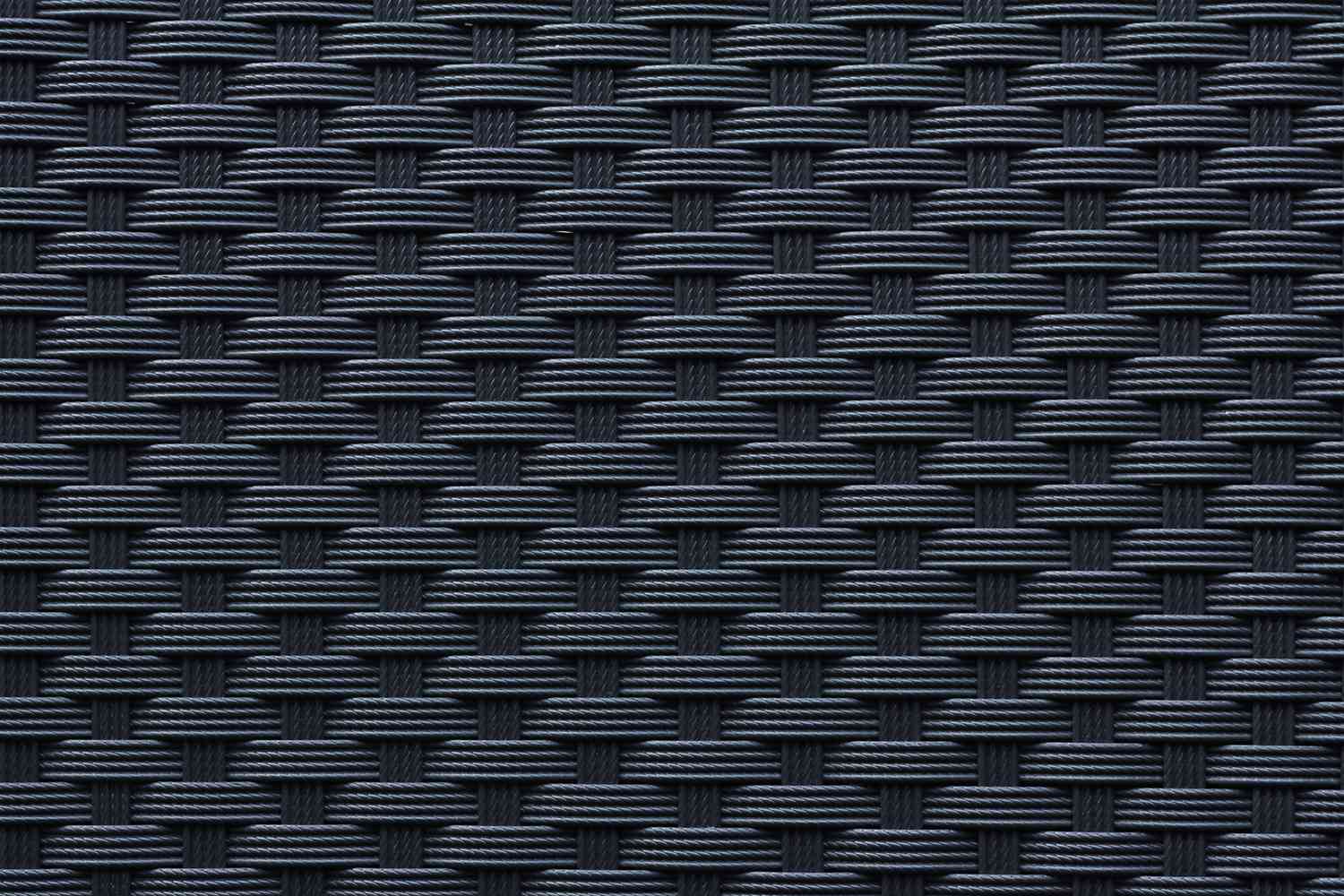

Esona siseko sibalulekileyo esibonakalayo se-carbon fiber se-fiber eqinisa izinto ezihlanganisiweyo ze-carbon filar.Izinto ezisisiseko ze-carbon ye-carbon yiPolyacyrlornfornnikarimitrley (Pan), iRayon, okanye iPetroleum.Iifilaments zekhabhoni zenziwa zibe ngamalaphu e-carbon fiber ngeendlela zeekhemikhali kunye neendlela zoomatshini kwiindawo ze-carbon fiber.

I-polymer ebophayo ihlala ihamba i-thermoset resin efana ne-epoxy.Ezinye ii-thermosets okanye i-thermoplastic polymers ngamanye amaxesha zisetyenziswa, njenge-polyvinyl acetate okanye inylon.Ukongeza kwimicu yekharbon, izihlunu zinokuqulatha i-Aramid Q, i-ultra-goone molethylene, ialuminiyam, okanye iintsinga zeglasi.Ipropathi yemveliso ye-carbon ye-fiber yokugqibela inokuchaphazeleka luhlobo lweezongezo ezingeniswe kwi-bondix ye-bondix.

Indlela yokuBumba yeCarbon Fiber eQiniswayo nePlastiki

Iimveliso ze-carbon fiber zahlukile ngenxa yeenkqubo ezahlukeneyo.Zininzi iindlela zokwakha i-carbon fiber eqinisa i-polymer.

1. Indlela yokuBeka izandla

Yahlulahlulwe yaba yindlela eyomileyo (ivenkile elungisiweyo) kunye nendlela emanzi (ifayibha yefayibha (i-wible ye-resic ihlawulwe).Ukulala ngesandla kukwasetyenziselwa ukulungiselela i-Pregregs ukuze isetyenziswe kwiinkqubo zokubumba zesibini ezifana nokubumba.Le ndlela kulapho amaphepha e-carbon fiber ilaphu inyibilikisiwe kwi-mold ukwenza imveliso yokugqibela.Amandla kunye nezixhobo zokuqina kwezinto eziphumlweni zilungiselelwe ngokukhetha ulungelelwaniso kwaye uluka ngeentsinga zelaphu.Umngundo ke uzaliswe nge-epoxy kwaye unyangelwe ngobushushu okanye ngomoya.Le ndlela yokuvelisa isoloko isetyenziselwa iindawo ezingagxininisiyo, njengezigqubuthelo zenjini.

2. Indlela yokwenza iVacuum

Kwi-prepreg elaminethiweyo, kuyimfuneko ukufaka uxinzelelo ngenkqubo ethile ukuyenza isondele kumngundo kunye nokunyanga kunye nokubumba phantsi kobushushu obuthile kunye noxinzelelo.Indlela ye-vacuum bag isebenzisa ipompo yokucoca ukukhupha ngaphakathi kwesikhwama sokubumba ukwenzela ukuba uxinzelelo olubi phakathi kwesikhwama kunye nesikhunta senze uxinzelelo ukwenzela ukuba izinto ezidibeneyo zisondele kwi-mold.

Kwisiseko sendlela yengxowa ye-vacuum beg, i-vacuum yengxowa yengxowa yengxowa yafumaneka kamva.I-Autoclaves ibonelela ngoxinzelelo oluphezulu kunye nobushushu inxenye (endaweni yonyango lwendalo) kunendlela yengxowa ye-vacuum kuphela.Inxalenye enjalo inesakhiwo esincinci, umgangatho ongcono wendawo, unokuphelisa ngokufanelekileyo iibhubhu zomoya (iibhubhu ziya kuchaphazela kakhulu amandla enxalenye), kwaye umgangatho wonke uphezulu.Ngapha koko, inkqubo yengxowa ye-vacuum ifana ne-filimu yefilimu yefilimu.Ukuphelisa iibbhu ze-air ngumsebenzi ophambili.

3. I-Compression Molding Method

Ukubumba ukunyanzeliswayindlela yokubumba elungele ukuveliswa kobuninzi kunye nemveliso yobuninzi.Izibungu zihlala zenziwa ngamacandelo aphezulu aphezulu, esikubiza ngokuba sisifo sobunjiweyo kunye nebhinqa.Inkqubo yokubumba kukubeka i-mat eyenziwe ye-prepregs kwi-mold counter yesinyithi, kwaye phantsi kwesenzo sobushushu obuthile kunye noxinzelelo, i-mat iyafudumala kwaye ifakwe kwiplastiki kwi-mold cavity, igeleza phantsi koxinzelelo, kwaye igcwalise umngxuma wokubumba, kwaye emva koko. Kwaye ukubumba kunye nokunyanga ukufumana iimveliso.Nangona kunjalo, le ndlela inexabiso eliphezulu kunangaphambili, kuba isisu sifuna ukubakho okuphezulu kwe-CNC.

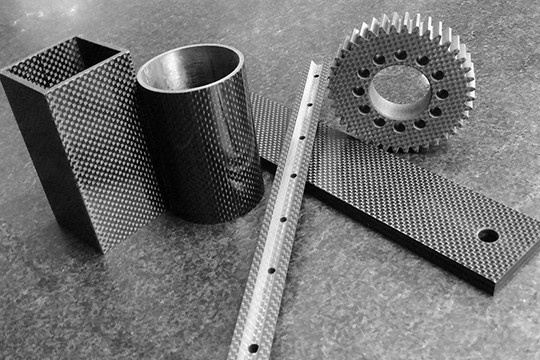

4. Ukubunjwa kwe-Winding

Kwiindawo ezineemilo ezintsonkothileyo okanye kwimilo ye-revolution yomzimba, i-filament winder ingasetyenziselwa ukwenza inxalenye ngokujija i-filament kwi-mandrel okanye i-core.Emva kokujija luphelile unyango kwaye ususe i-mandrel.Ngokomzekelo, iingalo ezidibeneyo ze-tubular ezisetyenziswa kwiinkqubo zokunqunyanyiswa zingenziwa ngokusebenzisa le ndlela.

5. I-Resin Transfer Molding

Ukubunjwa kwe-resin transfer (RTM) yindlela yokubumba eyaziwayo.Amanyathelo ayo asisiseko ngala:

1. Beka ilaphu elilungisiweyo le-carbon fiber kwi-mold kwaye uvale i-mold.

2. Thintela i-therimoset ye-terin ye-willn kuyo, ikhuphe izinto zokuqinisekisa ukuqina, kunye nokunyanga.

Iipropati zeCarbon Fiber eQiniswa nePolymer

(1) Amandla aphezulu kunye nexesha elifanelekileyo.

Amandla athile (oko kukuthi, umlinganiselo wamandla obunzima ukuya kubuninzi) we-carbon fiber ngama-6 amaxesha entsimbi kunye namaxesha angama-17 e-aluminium.Imodyuli ethile (oko kukuthi, umlinganiselo we-Young's modulus to density, owuphawu lokunyameka kwento) ngaphezu kwamaxesha ama-3 entsimbi okanye i-aluminium.

Ngamandla aphezulu, inokuthwala umthwalo omkhulu wokusebenza.Uxinzelelo lwayo oluninzi lokusebenza lunokufikelela kwi-350 kg / cm2.Ukongeza, iyacinezeleka kwaye yomelele kune-F-4 ecocekileyo kunye ne-braid yayo.

(2) Ukungaxhathisi kakuhle kwaye unxibe ukunganyangeki.

Ukumelana kwayo nokudinwa kuphezulu kakhulu kunoko kwe-epoxy resin kwaye kuphezulu kunoko kwemathiriyeli yentsimbi.Iifiber zegraphite ziyazithambisa kwaye zine-coefficient encinci yokukhuhlana.Ubungakanani bokugqoka buncinci ngamaxesha angama-5-10 kuneemveliso ze-asbestos eziqhelekileyo okanye i-F-4 braids.

(3) Ukusebenza okuhle kunye nokumelana nobushushu.

Iiplastiki zekhabhoni ezomeleziweyo zefiber zine-conductivity ye-thermal efanelekileyo, kwaye ubushushu obuveliswa kukukhuhlana buyachithwa ngokulula.Ingaphakathi akulula ukutshisa kunye nokugcina ukushisa kwaye ingasetyenziselwa njengento yokutywina eguquguqukayo.Emoyeni, inokusebenza ngokuzinzileyo kuluhlu lobushushu obuyi-120–350°C.Ngokunciphisa umxholo wesinyithi we-alkali kwi-carbon fiber, ubushushu benkonzo bunokwandiswa ngakumbi.Kwigesi engasebenziyo, ubushushu bayo obuguquguqukayo bunokufikelela malunga ne-2000 ° C, kwaye inokumelana nokutshintsha okubukhali kwingqele kunye nobushushu.

(4) Ukumelana nokungcangcazela kakuhle.

Akulula ukwenza isandi okanye ukuphaphazela, kwaye ikwayinto ebalaseleyo yokunciphisa ukungcangcazela kunye nokunciphisa ingxolo.

Izinto ezilungileyo zeCFRP

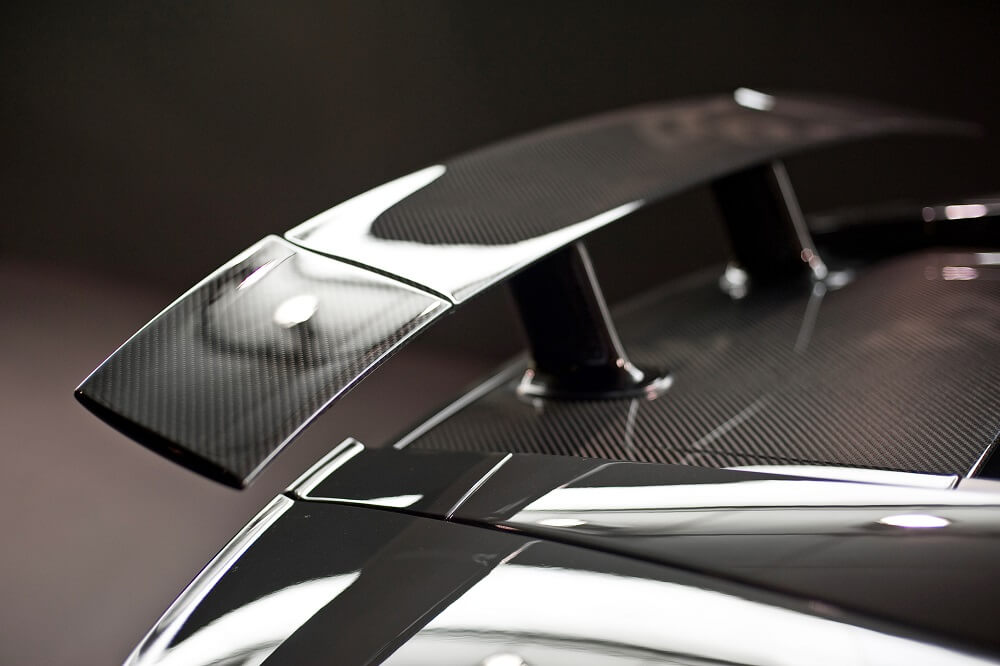

1. Ubunzima bokukhanya

Iiplastiki zeglasi eziqinisiweyo zemveli zisebenzisa iifiber zeglasi eziqhubekayo kunye ne-70% yeglasi yeglasi (ubunzima beglasi / ubunzima bubonke) kwaye ngokuqhelekileyo inoxinano lwe-0.065 pounds per cubic inch.Umdibaniso weCFRP kunye nobunzima befayibha ezingama-70% ngokuqhelekileyo unoxinano lwe-0.055 yeeponti nge-intshi nganye.

2. Amandla aphezulu

Nangona iipholima zekhabhoni ezomeleziweyo zikhaphukhaphu, imidibaniso yeCFRP inamandla aphezulu kunye nokuqina okuphezulu kwiyunithi nganye yobunzima kunemixube yefibre yeglasi.Xa kuthelekiswa nezinto zentsimbi, olu ncedo lucacile ngakumbi.

Izinto ezingalunganga zeCFRP

1. Iindleko eziphezulu

Iindleko zemveliso ye-carbon fiber eyomeleziweyo yeplastiki iyanqanda.Amaxabiso e-Carbon fiber anokwahluka kakhulu ngokuxhomekeke kwiimeko zemarike zangoku (ubonelelo kunye nemfuno), uhlobo lwe-carbon fiber (i-aerospace vs. ibakala lokuthengisa), kunye nobukhulu be-fiber bundle.Kwisiseko seponti yeponti, ifayibha yekhabhoni enyulu ingaba ngama-5 ukuya kwangama-25 amaxabiso exabiso ngaphezu kwefiber yeglasi.Lo mahluko mkhulu ngakumbi xa uthelekisa intsimbi neCFRP.

2. Ukuqhuba

Oku kuluncedo kunye nokungalungi kwezixhobo ze-carbon fiber composite.Kuxhomekeke kwisicelo.Iifiber zekhabhoni ziqhuba kakhulu kwaye iifiber zeglasi ziyakhusela.Iimveliso ezininzi zisebenzisa i-fiberglass endaweni ye-carbon fiber okanye intsimbi kuba zifuna ukufuduswa okungqongqo.Kwimveliso yezinto eziluncedo, iimveliso ezininzi zifuna ukusetyenziswa kweefiber zeglasi.

I-carbon fiber firliclectication isebenzisa

IIzicelo ze-carbon fiber iqinile i-polymerzibanzi ebomini, ukusuka kumatshini ukuya kwizinto zomkhosi.

(1)njengokupakisha

Izinto ze-PTFE ze-Carbon fiber zinokwenziwa zibe yi-corrosion-resistant, i-resistant-resistant, kunye nezangqa zokutywina ezinokumelana nobushushu obuphezulu okanye ukupakishwa.Xa isetyenziselwa ukutywinwa kwe-static, ubomi benkonzo bude, ngaphezu kwamaxesha e-10 ngaphezu kwe-oil-immersed asbestos packing.Inokugcina ukusebenza kokutywinwa phantsi kweenguqu zomthwalo kunye nokupholisa ngokukhawuleza kunye nokufudumeza ngokukhawuleza.Kwaye ekubeni izinto eziphathekayo aziqukethe izinto ezitshabalalisayo, akukho ukubola kwemigodi kuya kwenzeka kwintsimbi.

(2)njengeendawo zokusila

Isebenzisa iipropathi zayo zokuzithambisa, inokusetyenziswa njengeebheringi, iigiya, kunye namakhonkco episton ngeenjongo ezizodwa.Okufana neoyile-free lubricated iibheringi izixhobo ngenqwelomoya kunye neerekhoda tape, iigiya ioli-free lubricated kuthumelo lombane diesel locomotives (ukunqanda iingozi ezibangelwa ukuvuza ioyile), ioli-free intsimbi piston lubricated kwi compressors, njl Ukongeza, iyakwazi zikwasetyenziswa njengeebheringi ezityibilikayo okanye amatywina kumashishini okutya nawokuxuba amayeza ngokuthatha inzuzo yeempawu zayo ezingeyotyhefu.

(3) Njengezinto zolwakhiwo lwe-aerospace, inqwelomoya, kunye nemijukujelwa.Yaqala ukusetyenziswa kwimveliso yeenqwelomoya ukunciphisa ubunzima benqwelomoya kunye nokuphucula ukusebenza kakuhle kokubhabha.Ikwasetyenziswa kwikhemikhali, kwipetroleum, amandla ombane, oomatshini, nakwamanye amashishini njengokujikeleza okanye ukubuyisela isitywina esiguqukayo okanye izinto ezahlukeneyo zokutywina ezimile.

UZhengxi yincutsheUmzi-mveliso we-hydraulic press e-China, ukubonelela nge-quliatyicomposite hydraulic pressukwenza iimveliso ze-CFRP.

Ixesha lokuposa: May-25-2023