Glass Mat Reinforced Thermoplastic (GMT) is a novel, energy-saving, lightweight composite material with thermoplastic resin as the matrix and glass fiber mat as the reinforced skeleton. It is currently an extremely active composite material development variety in the world and is regarded as one of the new materials of the century.

GMT can generally produce sheet semi-finished products. It is then directly processed into the product of the desired shape. GMT has sophisticated design features, excellent impact resistance, and is easy to assemble and add. It is prized for its strength and lightness, making it an ideal structural component to replace steel and reduce mass.

1. Advantages of GMT Materials

1) High strength: The strength of GMT is similar to that of hand-laid polyester FRP products, and its density is 1.01-1.19g/cm. It is smaller than thermosetting FRP (1.8-2.0g/cm), therefore, it has a higher specific strength.

2) Lightweight and energy-saving: The weight of a car door made of GMT material can be reduced from 26 kg to 15 kg, and the thickness of the back can be reduced to increase the car space. The energy consumption is only 60%-80% of steel products and 35%-50% of aluminum products.

3) Compared with thermosetting SMC (sheet molding compound), GMT material has the advantages of a short molding cycle, good impact performance, recyclability, and a long storage cycle.

4) Impact performance: GMT’s ability to absorb shock is 2.5-3 times higher than SMC. SMC, steel, and aluminum all suffered dents or cracks under impact, but GMT remained unscathed.

5) High rigidity: GMT contains GF fabric, which can still maintain its shape even if there is an impact of 10mph.

2. Application of GMT Materials in the Automotive Field

GMT sheets have high strength and can be made into lightweight components. At the same time, it has high design freedom, strong collision energy absorption, and good processing performance. It has been widely used in the automotive industry since the 1990s. As the requirements for fuel economy, recyclability, and ease of processing continue to increase, the market for GMT materials for the automotive industry will continue to grow steadily.

At present, GMT materials are widely used in the automotive industry, mainly including seat frames, bumpers, instrument panels, hoods, battery brackets, foot pedals, front ends, floors, fenders, rear doors, roofs, luggage Components such as brackets, sun visors, spare tire racks, etc.

1) Seat frame

The second-row seatback compression-molded design on Ford Motor Company’s 2015 Ford Mustang (pictured below) sports car was designed by Tier 1 supplier/converter Continental Structural Plastics using Hanwha L&C’s 45% unidirectional glass-reinforced fiberglass mat thermoplastic Molds for composite materials (GMT) and Century Tool & Gage, compression molding. It successfully meets the extremely challenging European safety regulations ECE for maintaining baggage loads.

The part required more than 100 FEA iterations to complete, eliminating five parts from the earlier steel structure design. And it saves 3.1 kilograms per vehicle in a thinner structure, which is also easier to install.

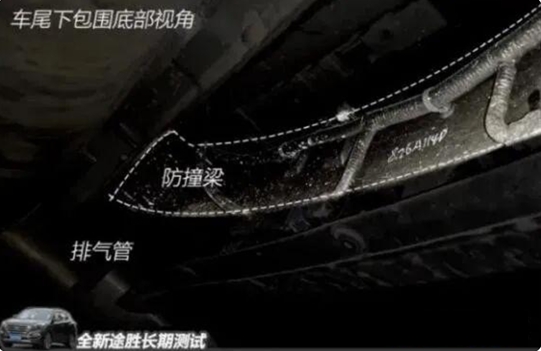

2) Rear anti-collision beam

The anti-collision beam at the rear of Hyundai’s new Tucson (see picture below) in 2015 is made of GMT material. Compared with steel materials, the product is lighter and has better cushioning properties. It reduces vehicle weight and fuel consumption while ensuring safe performance.

3) Front-end module

Mercedes-Benz has chosen Quadrant Plastic Composites GMTexTM fabric-reinforced thermoplastic composites as front-end module elements in its S-Class (pictured below) luxury coupe.

4) Body lower guard panel

Quadrant PlasticComposites uses high-performance GMTex TM for underbody hood protection for the Mercedes Off-Road Special Edition.

5) Tailgate frame

In addition to the usual advantages of functional integration and weight reduction, the formability of GMT tailgate structures also enables product forms not possible with steel or aluminum. Applied to Nissan Murano, Infiniti FX45, and other models.

6) Dashboard framework

GMT manufactures the new concept of dashboard frames intended for use on several Ford Group models: Volvo S40 and V50, Mazda, and Ford C-Max. These composites enable a wide range of functional integrations. Especially by incorporating the vehicle cross members in the form of thin steel tubes in the molding. Compared to traditional methods, the weight is significantly reduced without increasing the cost.

7) Battery holder

Post time: Jan-09-2024