Daim duab hlau sib sib zog nqus yog cov txheej txheem ntawm cov hlau nplaum stamping rau hauv hollow thooj voos kheej.Kev sib sib zog nqus duabPuas yog siv nyob rau hauv ntau cov txheej txheem ntau lawm, xws li hauv kev tsim cov tsheb hauv tsheb, nrog rau cov khoom siv hauv tsev, xws li cov chav dej stainless hlau.

Tus Txheej Txheem Tus Nqi:Maum cov nqi (tsis tshua muaj siab), chav nyob (nruab nrab)

Cov Khoom Uas Raug:Khoom Noj Khoom Haus thiab Dej Haus, Tab sis Khoom Siv Hauv Chav Ua Mov, Rooj Tog Zaum, Cov Teeb, Tsheb, Aerospace, thiab lwm yam.

Yiel tsim nyog:Haum rau Huab Ntau Lawm

Zoo:Qhov precision ntawm cov moulding nto yog tsis tshua muaj siab, tab sis cov ntaub ntawv tshwj xeeb ntawm cov pwm yuav tsum raug xa mus rau

Ceev:Lub sijhawm nrawm voj voog ib daim, nyob ntawm qhov ductility thiab compression tiv thaiv ntawm cov hlau

Muaj cov khoom siv

1. Cov txheej txheem teeb meem sib sib zog nqus yog nyob ntawm qhov sib npaug ntawm cov hlau ductility thiab compression kuj. Cov hlau tsim nyog: steel, tooj liab, zinc, txhuas alloy, thiab lwm yam hlau uas yooj yim los kua muag thiab wrinkle thaum lub sij hawm nqus sib sib zog nqus

2. Vim hais tias kev sib zog ntawm cov hlau ncaj qha cuam tshuam rau kev ua haujlwm zoo thiab zoo ntawm kev kos duab sib sib zog nqus, cov tawv ntoo hlau yog siv cov ntaub ntawv raw rau kev ua.

Kev txiav txim siab tsim

1. Lub cheeb tsam sab hauv ntawm ntu uas tsim los ntawm kev sib sib zog nqus yuav tsum tau tswj hwm thaum 5mm-500mm (0.2-16.69in).

2. Lub sijhawm ntev ntawm qhov ntev ntawm kev sib sib zog nqus duab yog nyob rau feem ntau 5 zaug ntawm sab hauv lub taub ntawm ntu ntu.

3. Qhov ntev dua qhov ntev ntev ntawm ib feem, cov tuab daim hlau. Txwv tsis pub, yuav muaj kev ntuag thaum ua vim tias cov ntawv tuab ntawm daim ntawv hlau yuav maj mam txo qis thaum lub sijhawm ncab.

Cov kauj ruam ntawm kev nqus nqus sib sib sib zog nqus

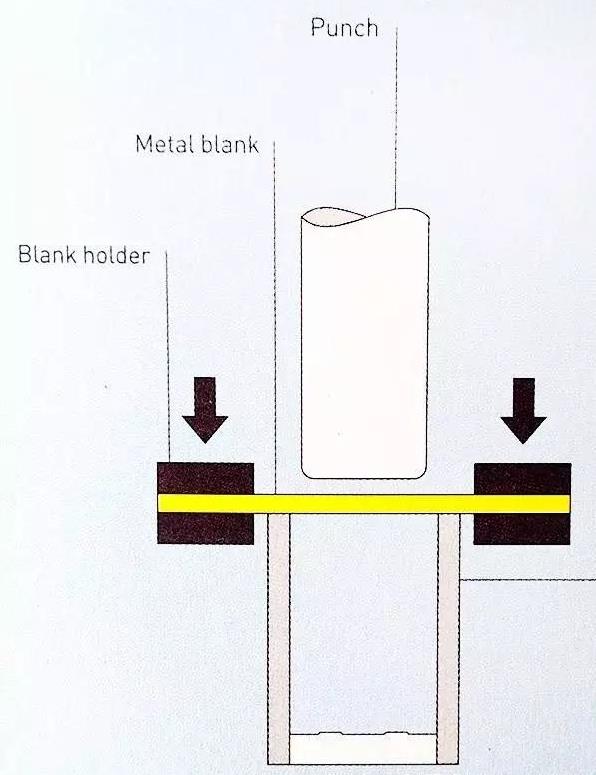

Kauj ruam 1: Kho cov txiav hlau daim ntawv rau cov xovxwm hydraulic

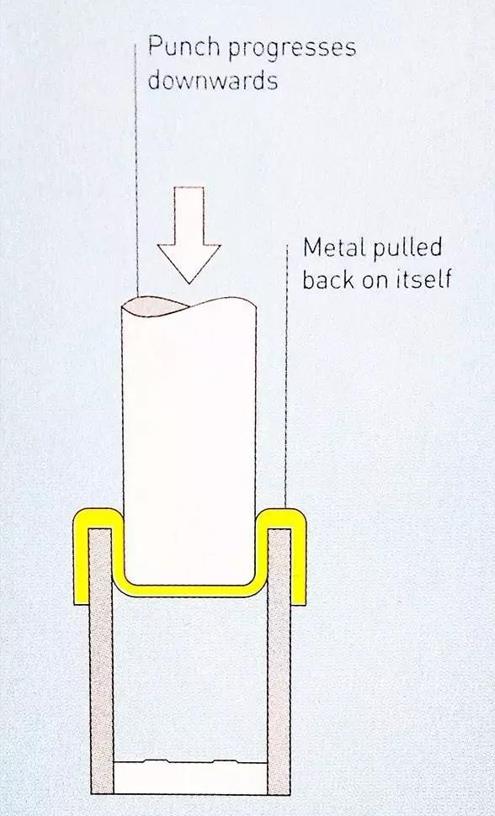

Kauj Ruam 2: Lub taub hau stamping nqis los thiab nyem cov ntawv hlau rau hauv cov pwm kom txog thaum daim ntawv hlau txuas nrog sab hauv phab ntsa ntawm cov pwm.

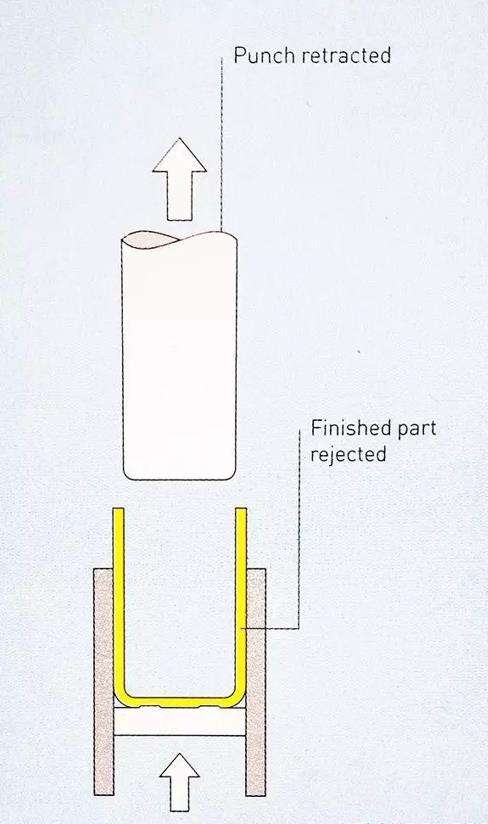

Kauj ruam 3: Lub taub hau stamping nce thiab ua tiav ib feem yog ntiab tawm los ntawm cov rooj hauv qab.

Cov Ntaub Ntawv Tiag

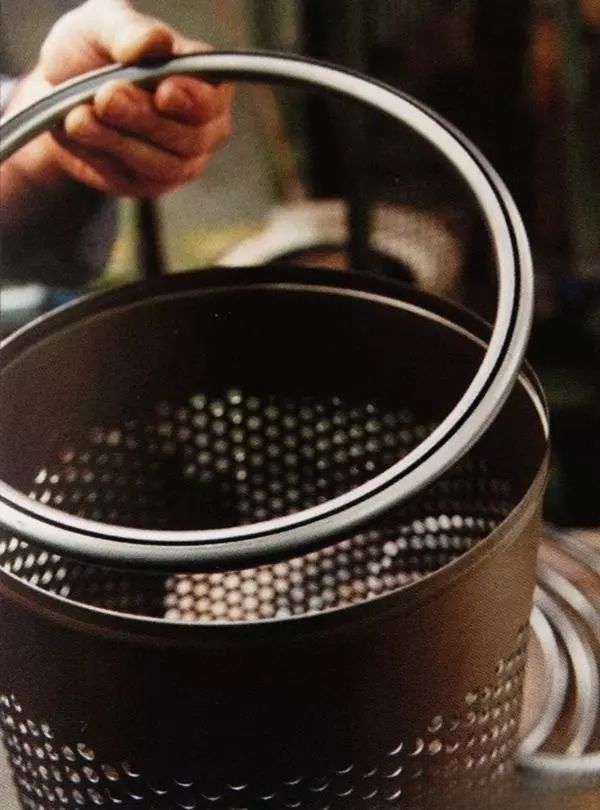

Kev tsim khoom cov txheej txheem ntawm hlau kaus thoob

Kauj ruam 1: Txiav 0.8mm (0.031in) tuab cov hlau steel tuab rau hauv cov khoom qab zib ib puag ncig.

Kauj Ruam 2: Txhim kho cov ntawv txiav cov hlau nplaum ntawm cov xovxwm hydraulic (tsau los ntawm clamps ib ncig ntawm hydraulic xovxwm platform).

Kauj ruam 3: Lub taub hau stamping nqis siab qeeb, extruding cov ntawv hlau ua hlau rau hauv pwm.

Kauj Ruam 4: Lub Taub Hau Stamping nce, thiab cov hlau tsim lub tog raj kheej tau muab.

Kauj Ruam 5: TRIMMING

Kauj ruam 6: Polish

Lwm cov khoom sib sib zog nqus hlau cov khoom

Lub Sijhawm Post: Apr-13-2023