Eli nqaku lizisa izizathu zokusilelaI-Hydraulic cinezelaIzisombululo kunye nezisombululo.

1. Izinto eziMnyama

I-SEELT yensimbi ye-alloy yentsimbi. Kukho iziphene ezinjenge-insulings, i-carbide yokwahlulahlula, iipores eziphambili kunye namabala amhlophe kwisakhiwo, esinciphisa kakhulu amandla, ukuqina kunye nokungakhathali kwe-thermal. Ngokubanzi, yahlulahlulwe yangamafutha aqhelekileyo kwaye iphakathi komgangatho. Ngenxa yetekhnoloji yemveliso ephambili, i-molds ephakathi icocekile icocekile kumgangatho, iyunifomu yesakhiwo, encinci kubungqingqwa, kwaye inobunzima obuphezulu kunye nokudinwa kweengxaki ze-thermal.

Isisombululo: Ukutsala izifo eziqhelekileyo ukophula i-inzuzo enkulu engekafihli, ukuphelisa ukwahlula kwe-carbide, hlaziya i-carbides, kwaye wenze i-iyunifomu ephezulu.

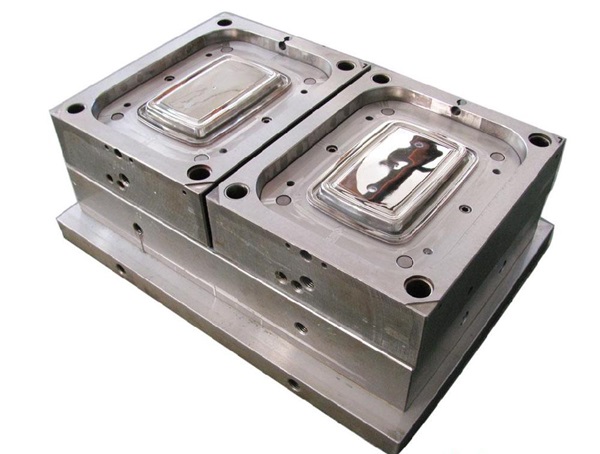

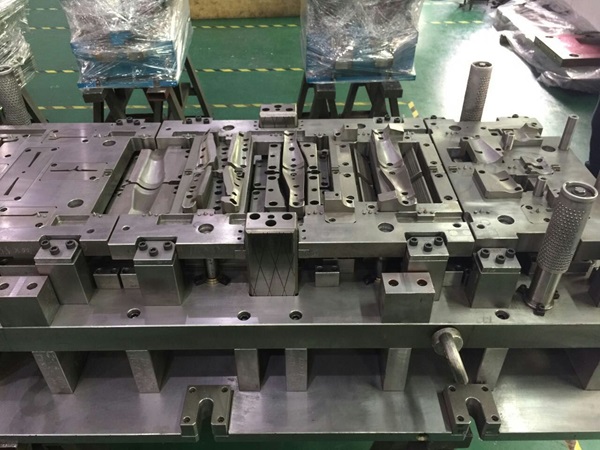

I-2. Uyilo lweMolds

Xa uyilo lwe-MOLD, ubukhulu bemodyuli yemodyuli kufuneka bugqitywe ngokwemibambo kunye nemilinganiselo yejometri yenxalenye yokuqinisekisa amandla okubumba. Ukongeza, ngexesha lonyango lobushushu kunye nokusetyenziswa kobumba, ngenxa ye-fillet ye-fillet, icandelo elibanzi lodonga, kunye nesikhundla esingalunganga somngxunya kunye ne-slot, kulula ukubangela uxinzelelo olugqithisileyo kunye nokuqhekeka koxinzelelo. Uyilo olubulqwa kufuneka luphephe iikona ezibukhali kangangoko kunokwenzeka, kwaye umngxunya kunye nezikhundla zeSlot kufuneka zilungelelaniswe kakuhle.

I-3. Inkqubo yokwenziwa

I-1) inkqubo yokufowuna

I-MOLD iqulethe izinto ezininzi ze-Afloy, inesiphene esikhulu sokungakhathali ngexesha lokukrazula, ukuqhutywa kwengqondo okuphantsi, kunye nobushushu obuphantsi. Ukuba awukwazi ukunikela ingqalelo, iya kubangela ukungaphumeleli kokubumba. Ifanele ithathelwe ingqalelo nge-800-900 ℃ emva koko ifudumele ukuya kwi-1065-175 ℃. Ukususa indawo enkulu engafikeleliyo, ukuphelisa ukwahlula i-carbide, kunye nokuphucula i-carbides, ukucaphukisa kunye nokuzoba kufuneka kuphindwe ngexesha lenkqubo yombutho oqinisekileyo. Ngexesha lenkqubo yokupholisa emva kokubamba, ukucima i-cracks zihlala ziveliswa. Kulula ukuvelisa izikrelem eziguqukayo embindini. Ukuphola kancinci emvaukufowunaUngayiphepha le ngxaki.

2) Ukusika

Ubunzima benkqubo yokusika buchaphazela kakhulu intsebenzo yomnyama. Ubungqingqwa bokuqina komda busezantsi, kwaye akukho ziphene zinjengesiphango sokukhweza, ukukrala, kunye nokugqubuka, okuya kubangela uxinzelelo lwe-thermal kwaye ibangele ukuba kuqaliswe.

Isisombululo: Xa kusenziwa isisu, ukuthintela amanqaku e-phandle ukuba ungashiywa kwiradiyo yendawo yembombo. Kwaye icime i-rors kwimingxunya, i-groove imiphetho kunye neengcambu.

3) Ukugaya

Ngexesha lenkqubo yokugaya, ubushushu obuxineneyo bunokubangela ngokulula iziphene ezifana nokutshisa i-punns kunye nokuvelisa uxinzelelo lwentsalela kumphezulu we-gramas, okhokelela ekungaphumleni kwangaphambi kokubumba. Ukuvutha okubangelwa bubushushu bokugaya kunokucaphuka umbungu de kube kumiswa uMartenite. I-Brittle kwaye ayizange isebenze uMartenite ungqiniwo uya kunciphisa kakhulu ukusebenza kwe-thermal. Xa ubushushu bendawo bunyuka bungaphezulu kwe-Grinding bud Right idlula i-800 ℃, kwaye ukupholisa akonelanga, izinto ezingaphezulu komhlaba ziya kuphinda ziphinde zithintelwe kwaye zicinywe kwi-martiensite. Umphezulu wobumba uza kuvelisa uxinzelelo oluphezulu. Ukunyuka kobushushu bomgangatho wobunzi kuya kuvelisa uxinzelelo lwe-thermal ngexesha lokugaya, kunye nokungaphezulu kwenkqubo yolwakhiwo kunye noxinzelelo lwe-thermal kunokubangela ngokulula ukugoba kubumba.

I-4) Ookhokho be-electroscork

Umatshini womatshini we-electrospal yindlela yokugqibelela i-elektroniki kwinkqubo yokwenziwa komzimba yanamhlanje. Xa i-spark ikhutshiwe, ubushushu bendawo yendawo engaphezulu kwe-1000 ℃, ke intsimbi kwindawo yokukhupha inyibiba kwaye ivule. Kukho umaleko omncinci wensimbi eqingqiweyo kwaye ecocekileyo kumphezulu womatshini we-elektrostark. Zininzi ii-microcrack kuyo. Lo mgama mncinci wesinyithi mhlophe. Phantsi komthwalo wokubumba, ezi zinto zincinci ezikrwelayo kulula ukuba ziphuhliswe kwi-macro crock, zikhokelela ekuqhekekeni kwasekuqaleni nokunxiba.

Isisombululo: Emva kweenkqubo ze-EDM, isisu somoya sivutha ngumsindo ukuze siphelise uxinzelelo lwangaphakathi. Nangona kunjalo, ubushushu bobushushu bungabi ngaphezu kweqondo lobushushu eliphezulu phambi kwe-EDM.

I-5) Inkqubo yonyango lobushushu

Inkqubo yonyango enobushushu inokwenza ukuba ibumba ifumane iipropathi ezifunekayo zoomatshini kunye nokuphucula ubomi benkonzo. Ukuba uyilo lonyango lwenkqubo yobushushu okanye ukusebenza akulunganga kwaye kubangela ukubumba, kuya konakalisa amandla okubumba kombungu, kukhokelela ekungaphumeleli kwasekuqaleni kwaye kunciphise ubomi benkonzo. Isiphene sonyango lobushushu sibandakanya ukugxeka, ukugqobhoza, ukuqhekeza, ukuqhekeza, ukuqokelela koxinzelelo lwangaphakathi, ukukhululwa okungapheliyo kunye nokwenza umlinganiso kunye nomlinganiso kufuneka lwenziwe. Ngaphandle koko, ukubumba kuya kuqhekezwa ngenxa yoxinzelelo lwangaphakathi xa iqhubeka isetyenziswa.

I-4. Ukusetyenziswa kwezikhunta

I-1) Ukuhenyuza iimbumbulu

Umbungu unomxholo ophezulu we-alloy kunye nokuqhutywa kwe-shirt ephantsi. Kufuneka iphinde ichazwe ngokupheleleyo ngaphambi komsebenzi. Ukuba iqondo lobushushu elibumba liphezulu kakhulu ngexesha lokusetyenziswa, amandla aya kuncipha, kwaye ukungcungcutheka kweplastiki kuya kwenzeka ngokulula, kukhokelela ekuweni kwesithoko. Xa iqondo lobushushu elandulelayo liphantsi kakhulu, ubushushu obucekeceke obukhawulezileyo buguquka kakhulu xa isikhunta siqala ukusetyenziswa, uxinzelelo lwe-thermal lukhulu, kwaye kulula ukubhuqa.

Isisombululo: Iqondo lobushushu le-mold elihamba phambili lizimisele ukuba ngama-250-300 ℃. Oku akunakukwazi ukunciphisa umahluko wobushushu bokufa kwaye uphephe uxinzelelo lwe-thermal egqithisileyo kumhlaba wobumba kodwa unciphise ngokufanelekileyo iplastiki kwi-onmold.

2) ukubumba ukupholisa kunye nokuthambisa

Ukunciphisa umthwalo wobushushu obububuyo kwaye uphephe ubushushu obuphezulu, isisu sihlala sinyanzeliswa ukuba sipholile ngexesha lesithuba sokugoda. Ukufudumeza ngamaxesha ngamaxesha kunye nokupholisa ubumba kuya kubangela ukuba kutyeke. Ubumba kufuneka buthotyelwe kancinci emva kokusetyenziswa; Ngaphandle koko, uxinzelelo lwe-thermal luya kwenzeka, lukhokelwe kukuqhekeka komnyama kunye nokusilela.

Isisombululo: Xa isisu siyasebenza, igrafu esekwe emanzini enomxholo we-12% inokusetyenziselwa ukunciphisa amandla okunciphisa, kuqinisekiswe ukuhamba kwesinyithi kwintsimbi kwaye kugudise ukukhululwa kwentsimbi. Igrafu yegraphite ye-graphtite ikwanemiphumo yobushushu, enokunciphisa ubushushu obusebenzayo.

Ezi zinto zilapha ngasentla zizizathu nezisombululo ze-hydraulic cofa contasf ngaphandle kokusilela.ZhengxiNgaba umenzi womenziI-Hydraulic Printa izixhobo. Ukuba ufuna nantoni na, nceda uqhagamshelane nathi.

I-POSTAL: I-DEC-24 ukuya kwi-2024