Le ndatshana yethula ikakhulukazi izizathu zokwehluleka kwePress hydraulicisikhunta nezixazululo.

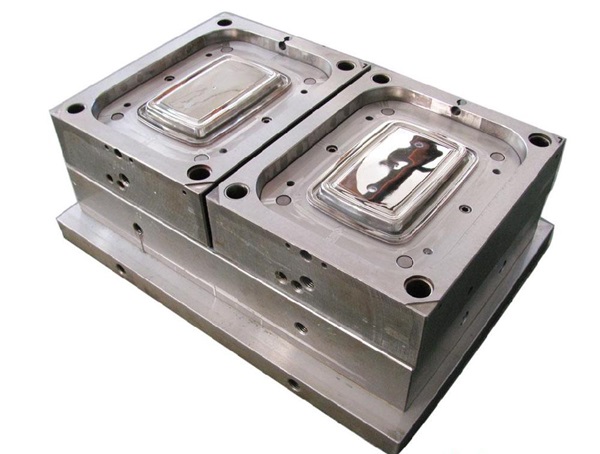

1. I-Mold Material

Insimbi yokubamba ingeyakwensimbi yensimbi. Kunezinkinga ezinjenge-inclusions ezingezona zensimbi, ukuhlukaniswa kwe-carbide, ama-pores aphakathi nendawo kanye namabala amhlophe esakhiweni sawo, anciphisa kakhulu amandla, ukuqina nokungamelana nokushisa okushisayo kwesikhunta. Ngokuvamile, ihlukaniswe yaba isikhunta esezingeni eliphakeme futhi esezingeni eliphakeme ngokwekhwalithi. Ngenxa yobuchwepheshe bokukhiqiza obuthuthukile, isikhunta esezingeni eliphakeme simsulwa ngekhwalithi, umfaniswano ngesakhiwo, esincane ekuhlukaniseleni, futhi sinokusebenza okuphezulu nokungasebenzi kahle okushisayo kanye nokusebenza kokukhathala okushisayo.

Isixazululo: Ukwakha isikhunta esijwayelekile ukwephula ukuthathwa okukhulu kwensimbi, susa ukuhlukaniswa kwe-carbide, ukucwilisa i-carbides, bese wenza umfaniswano wesakhiwo ukufeza umphumela wokubumba osezingeni eliphakeme.

2. Ukuqamba isikhunta

Lapho uklama isikhunta, ubukhulu bemodyuli banganqunywa ngokuya ngobukhulu bezinto ezibonakalayo nejometri yengxenye eyakhiwe ukuze baqinisekise amandla okubumba. Ngaphezu kwalokho, ngesikhathi sokwelashwa kokushisa nokusetshenziswa kwesikhunta, ngenxa yemisebe emincane ye-fillet, isigaba esikhulu sodonga oludongeni, umehluko omkhulu wodonga, kulula ukudala ukugxilisa ingqondo nokuqhekeka. Idizayini yokubumba kufanele igweme amakona abukhali ngangokunokwenzeka, futhi umgodi nezikhundla ze-slot kufanele zihlelwe ngokunengqondo.

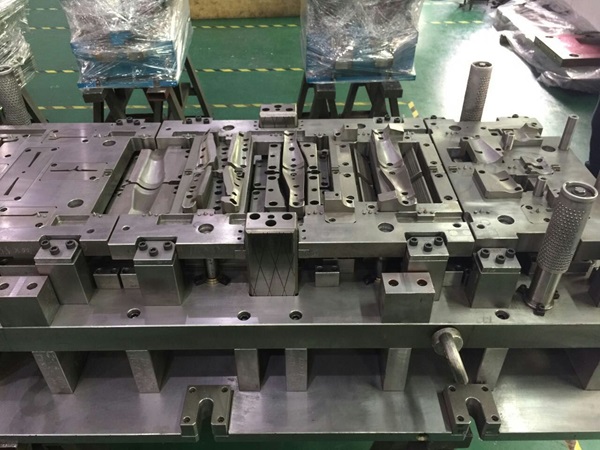

3. Inqubo Yokukhiqiza

1) Inqubo yokukhokhela

Isikhunta siqukethe izinto eziningi ze-alloy, zinokumelana okukhulu kwezimo ezingezona ngesikhathi sokuvuselela, ukuqina okungekho emthethweni, kanye nokushisa okuphansi kwe-eutectic. Uma unganaki, kuzodala ukwehluleka kokubumba. Kufanele kushaywe kushaqeka ku-800-900 ℃ bese kufudumeza ku-1065-1175 ℃. Ukususa inclusions enkulu engeyona yensimbi, susa ukuhlukaniswa kwe-carbide, kanye nokuhlaziywa kwe-carbides, ukucasula nokudweba kufanele kuphindwe ngesikhathi senqubo yokwakha ngenhlangano efanayo. Ngesikhathi senqubo yokupholisa ngemuva kokukhipha, ukucima imifantu kuvame ukukhiqizwa. Kulula ukukhiqiza imifantu eguqukayo enkabeni. Kuhamba kancane kupholile ngemuvaukuthethelelaungayigwema le nkinga.

2) ukusika

Ubulukhuni bendawo yenqubo yokusika luthonya kakhulu ukusebenza kokukhathala okushisayo kwe-mold. Ubulukhuni bendawo yombumba buphansi, futhi akukho zici ezinjengemaka wommese, imihuzuko, kanye nemisebe, ezodala ukugxila kwengcindezi futhi ibangele ukukhathala kokukhathala okushisayo ukuze uqale.

Isixazululo: Lapho ucubungula isikhunta, vimba amamaki ommese ekushiyweni emsakazweni wamakhona ezingxenye eziyinkimbinkimbi. Bese ugaya ama-burrs ezimbobo, imiphetho yezimpande nezimpande.

3) Ukugaya

Ngesikhathi senqubo yokugaya, ukushisa kwezingxabano zasendaweni kungadala kalula izici ezinjengokushiswa kanye nemifantu futhi zikhiqize ukucindezelwa okusele okusele ekugayeni indawo yokugaya, okuholela ekuhlulekeni ngaphambi kwesikhathi kwesikhunta. Ukushiswa okubangelwa ukushisa kokugaya kungashukumisela indawo yokubumba kwaze kwakhiwa umfelokazi ofanele. Isendlalelo se-Martensite esingenamikhawulo kanye ne-undersered anciphisa kakhulu ukusebenza kokukhathala okushisayo kwesikhunta. Lapho izinga lokushisa lendawo likhuphuka indawo yokugaya lidlula ama-800 ℃, futhi ukupholisa akwanele, izinto ezingaphezulu zizophinde ziguqulwe futhi zicinywe ku-Martensite. Indawo yokubumba izokhiqiza ingcindezi ephakeme yesakhiwo. Ukukhuphuka kwezinga lokushisa kwesikhuntana kuzokhiqiza ukucindezelwa okushisayo ngesikhathi senqubo yokugaya, futhi inqubo yokuxineka kwesakhiwo nashisayo ingadala kalula ukuqhekeka kokugaya ku-isikhunta.

4) I-Electrospark Machching

I-ElectroSpark Machching iyindlela ebaluleke kakhulu yokuqeda inqubo yokukhiqiza isikhunta sanamuhla. Lapho kwenzeka ithanga, izinga lokushisa lendawo lidlula i-1000 ℃, ngakho-ke insimbi ephakanyiselwe iphuzu lincibilika futhi lihlobise. Kukhona ungqimba omncane wensimbi oncibilikisiwe futhi olunganqunyelwe ngaphezulu kwemishini ye-electroospark. Kunama-microcrack amaningi kuwo. Lo ungqimba omncane wensimbi lukhanya mhlophe. Ngaphansi komthwalo wobumba, lokhu kufakelwa amancane akulula ukuthuthuka kube ukuqhekeka kwe-macro, okuholela ekuqhekekeni kokuqala nokugqoka kwalesi sibumba.

Isixazululo: Ngemuva kwezinqubo ze-EDM, isikhunta sinomoya wokuqeda ukucindezela kwangaphakathi. Kodwa-ke, izinga lokushisa elinolaka akufanele lidlule amazinga okushisa afudumele ngaphambi kwe-EDM.

5) Inqubo yokwelashwa kokushisa

Inqubo yokuthola ukwelashwa okunengqondo ingavumela isikhunta ukuthola izakhiwo ezidingekayo zemishini futhi sithuthukise impilo yayo yenkonzo. Uma ukuklanywa kwenqubo yokushisa noma ukusebenza kungafanele futhi kubangela ukuba isikhunta sehluleke, kuzolimaza kakhulu amandla okuvuselela isikhunta, okuphumela ekuhlulekeni kusenesikhathi futhi kunciphise impilo yenkonzo. Ukulimala kokwelashwa okushisa kufaka phakathi ukwehla ngokweqile, okubeka ngokweqile, ukuqhekeka, ukuqhekeka, ungqimba oluqine, ubulukhuni obunganele, njll. Ngemuva kwesikhathi sokusetshenziswa, lapho kutholwa khona ukucindezelwa kwengcindezi. Ngaphandle kwalokho, isikhunta sizokwehla ngenxa yokuxineka kwangaphakathi lapho kuqhubeka kusetshenziswe.

4. Ukusetshenziswa kwezikhunta

1) Ukushiswa komndeni

Isikhunta sinokuqukethwe okuphezulu kwe-alloy kanye nokusebenza okungekho emthethweni. Kufanele kusethwa isentukwe ngokuphelele ngaphambi komsebenzi. Uma izinga lokushisa elibunjiwe liphezulu kakhulu ngesikhathi sokusebenzisa, amandla azokwehla, futhi i-deformation yepulasitiki izokwenzeka kalula, okuholela ekuwohlolweni kwesikhunta. Lapho izinga lokushisa le-preheating liphansi kakhulu, izinga lokushisa elingaphezulu lishintsha kakhulu lapho isikhunta siqala ukusetshenziswa, ukucindezelwa okushisayo kukhulu, futhi kulula ukuqhekeka.

Isixazululo: Ukushisa komkhuhlane kuzimisele ukuba ngu-250-300 ℃. Lokhu akukwazi ukunciphisa kuphela ukubulawa kokufa kokushisa umehluko futhi uvikele ukucindezelwa okushisayo ngokweqile endaweni ebunjiwe kodwa futhi kunciphisa ngempumelelo ukuphuma kwepulasitiki endaweni ebunjiwe.

2) isikhunta sokupholisa nokuthambisa

Ukuze unciphise umthwalo wokushisa wesikhunta futhi uvikele amazinga okushisa aphezulu, isikhunta kwesinye isikhathi siphoqeleka ukuba siphole ngesikhathi sokubumba. Ukushisa ngezikhathi nokupholisa kokubumba kuzodala ukuqhekeka kokukhathala okushisayo. Isikhunta kufanele sehliswe kancane ngemuva kokusebenzisa; Ngaphandle kwalokho, kuzokwenzeka ukucindezela okushisayo, okuholela ekuqhekekeni kokubumba nokwehluleka.

Isixazululo: Lapho isikhunta sisebenza, i-graphite esuselwa emanzini enokuqukethwe kwe-graphite engu-12% ingasetshenziselwa ukuthambisa ukunciphisa amandla akhe, kuqinisekiswe ukuhamba okujwayelekile kwensimbi emgodini futhi kubusheleleke ukukhishwa kokukhishwa. I-Graphite Tyhomula futhi inomphumela wokuhlanza ukushisa, okunganciphisa izinga lokushisa elisebenzayo.

Lokhu okungenhla kunezizathu nezisombululo ze-hydraulic Press ukwehluleka isikhunta.Zhengxiungumkhiqizi ochwepheshe ngaphakathiimishini yokushicilela ye-hydraulic. Uma udinga noma yini, sicela uthintane nathi.

Isikhathi sePosi: Dec-24-2024