1. Kuʻu wale forging

ʻO ka forging manuahi e pili ana i ke kaʻina hana o ka hoʻohana ʻana i nā mea hana maʻalahi maʻalahi a i ʻole ka hoʻopili pololei ʻana i kahi ikaika o waho i ka blank ma waena o nā anvils luna a me lalo o nā mea hana forging e hoʻololi i ka blank e loaʻa ai nā forgings me ke ʻano geometric pono a me ka maikaʻi o loko.

Hoʻopuka nui ka forging manuahi i nā ʻāpana liʻiliʻi.Hoʻohana ʻia nā mea hana forging e like me ka forging hammers a me nā kaomi hydraulic e hana i nā blanks e loaʻa ai nā forgings kūpono.Hoʻohana ʻo Free forging i ke ʻano hana forging wela.

ʻO ke kaʻina hana forging manuahi e pili ana i kahi kaʻina kumu, kahi hana kōkua, a me kahi kaʻina hoʻopau.

ʻO ke kaʻina hana kumu o ka hoʻoheheʻe manuahi ʻana ʻo ia ka huhū, ke kaha kiʻi, ke kuʻi ʻana, ke kuʻi, ka ʻoki ʻana, ka wili, ka hoʻololi ʻana a me ka hana ʻana, a pēlā aku.

Kaʻina hana kōkua: ka hana pre-deformation, e like me ke kaomi ʻana i ka iwi āpau, kaomi ʻana i ka lihi o ka ingot kila, ʻoki i ka poʻohiwi, etc.

Ke kaʻina hana hoʻopau: ke kaʻina hana e hōʻemi i nā hemahema o ka ʻili o ka forgings, e like me ka wehe ʻana i ka like ʻole a me ke ʻano o ka ʻili forging.

Pōmaikaʻi:

(1) He mea nui ka hoʻololi ʻana, hiki iā ia ke hana i nā ʻāpana liʻiliʻi ma lalo o 100kg.A hiki iā ia ke hana i nā ʻāpana kaumaha a hiki i 300t.

(2) ʻO nā mea hana i hoʻohana ʻia he mau mea hana maʻalahi.

(3) ʻO ka hana ʻana o nā forgings e hoʻololi mālie i ka blank ma nā wahi like ʻole.No laila, ʻoi aku ka liʻiliʻi o ka tonnage o nā mea hana forging e pono ai no ka hoʻopaʻa ʻana i ka forging like ma mua o ka forging die.

(4) Nā koi haʻahaʻa haʻahaʻa no nā mea hana.

(5) He pōkole ka pōʻaiapili hana.

Nā hemahema:

(1) ʻOi aku ka haʻahaʻa o ka hana hana ma mua o ka make forging.

(2) He ʻano maʻalahi ko ka forgings, haʻahaʻa haʻahaʻa ka pololei, a me nā ʻili ʻākala.

(3) He kiʻekiʻe ka ikaika o ka poʻe hana a koi i nā pae ʻenehana kiʻekiʻe.

(4) ʻAʻole maʻalahi ka hoʻomaopopo ʻana i ka mechanization a me ka automation.

2. Make forging

ʻO ka die forging e pili ana i ke ʻano forging kahi e loaʻa ai nā forgings ma o ka hana ʻana i nā blanks me nā mea make ma nā mea hana hoʻoheheʻe make kūikawā.ʻO nā forgings i hana ʻia e kēia ʻano hana pololei i ka nui, liʻiliʻi i ka ʻae mīkini, paʻakikī i ke ʻano, a kiʻekiʻe i ka huahana.

Hoʻokaʻawale ʻia e like me nā mea i hoʻohana ʻia: make forging ma ka hāmare, make forging ma ka crank press, make forging on the flat forging machine, make forging on friction press, etc.

Pono:

(1) ʻOi aku ka maikaʻi o ka hana ʻana.I ka wā make forging, lawe ʻia ka deformation o ka metala i loko o ka lua make, no laila hiki ke loaʻa koke ke ʻano i makemake ʻia.

(2) Hiki ke hoʻopololei ʻia nā ʻano hana paʻakikī.

(3) Hiki iā ia ke hana i ka hāʻawi ʻana i ka streamline metala i kūpono a hoʻomaikaʻi i ke ola lawelawe o nā ʻāpana.

(4) ʻOi aku ka pololei o ka nui o ka die forging, ʻoi aku ka maikaʻi o ka ʻili, a ʻoi aku ka liʻiliʻi o ka haʻawina mīkini.

(5) E mālama i nā mea metala a hoʻemi i ka ʻoki ʻana i ka hana.

(6) Ma lalo o ke kūlana o nā pahu kūpono, hiki ke hoʻemi ʻia ke kumukūʻai o nā ʻāpana.

Nā hemahema:

(1) Ua kaupalena ʻia ke kaumaha o nā mea hoʻoheheʻe make ma muli o ka hiki o nā mea hana hoʻoheheʻe maʻamau, ʻoi aku ka nui ma lalo o 7 kg.

(2) He lōʻihi ka pōʻai hana o ka make forging a he kiʻekiʻe ke kumukūʻai.

(3) ʻOi aku ka nui o ke kumukūʻai hoʻopukapuka o nā lako hana make forging ma mua o kopaʻi kalai manuahi.

3. ʻO ka hana ʻana i ka ʻōwili

ʻO ka hoʻowili ʻana e pili ana i kahi kaʻina hana e hoʻohana ʻia ai nā mea like ʻole o ka peʻahi kūʻē i ka huli ʻana e hoʻololi i ka billet no ka loaʻa ʻana o ka billet i makemake ʻia.

Roll forging deformation mea he paʻakikī ekolu-dimensional deformation.ʻO ka hapa nui o nā mea deformed e kahe ana ma ka ʻaoʻao lōʻihi e hoʻonui i ka lōʻihi o ka billet, a ʻo kahi hapa liʻiliʻi o ka mea e kahe ana ma hope e hoʻonui i ka laulā o ka billet.I ka wā o ke kaʻina hana ʻōwili, e emi mau ana ka ʻāpana kea o ka aʻa billet.Ke hoʻohana nei ke kaʻina hana ʻōwili i ka loina o ka ʻōwili ʻana e hoʻololi mālie i kahi hakahaka.

He kūpono ka ʻōwili ʻana no nā kaʻina deformation e like me ka elongating shafts, rolling slabs, a me ka hāʻawi ʻana i nā mea ma ke ala lōʻihi.Hiki ke hoʻohana ʻia ka palaka ʻōwili no ka hana ʻana i nā koʻokoʻo hoʻohui, wili i nā ʻāpana drill, nā wrenches, nā spike alanui, nā hoe, nā ʻohi a me nā lau turbine, etc.

Ke hoʻohālikelike ʻia me ka make maʻamau, ʻo ka roll forging ka mea maikaʻi o ka hoʻolālā ʻana o nā mea hana maʻalahi, ka hana paʻa, haʻahaʻa haʻahaʻa a me ka walaʻau, maʻalahi ka automation, a me ka hana kiʻekiʻe.

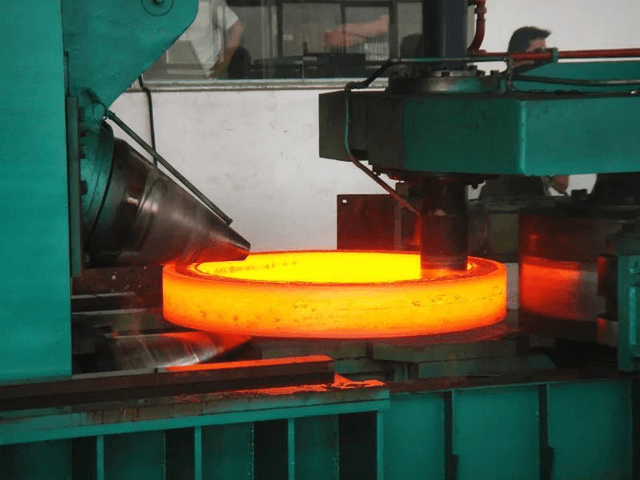

4. Hoʻopalapala ʻia ʻo Tire make

ʻO ka hoʻoheheʻe ʻana i ka paopao he ʻano hana hoʻoheheʻe ʻia e hoʻohana i ke ʻano hoʻoheheʻe manuahi e hana i kahi hakahaka, a laila hana ʻia i loko o ka mold tire.He hana forging ma waena o ka forging manuahi a me ka forging make.Hoʻohana nui ʻia ia i nā ʻoihana liʻiliʻi a me nā ʻoihana liʻiliʻi me ka liʻiliʻi o ka make forging lako a ʻo ka hapa nui o lākou he mau hāmare forging manuahi.

Nui nā ʻano ʻano o nā ʻōpala i hoʻohana ʻia i ka hoʻoheheʻe ʻana i ka pahu, a ʻo nā mea maʻamau i ka hana ʻana he type drop, buckle mold, set mold, cushion mold, clamping mold, etc.

Hoʻohana nui ʻia ka make cylinder paʻa no ka hana ʻana i nā forging rotary.No ka laʻana, hoʻohana ʻia nā mea hana me nā luna ma nā ʻaoʻao ʻelua no ka hana ʻana i nā forging non-revolving.ʻO ka hoʻopaʻa ʻia ʻana o ka cylinder die forging he flash-free forging.

No ka hoʻoheheʻe ʻia ʻana o nā huila me nā ʻano paʻakikī, pono e hoʻohui i ʻelua mau hapalua hapalua (ʻo ia hoʻi, e hoʻohui i kahi ʻāpana ʻāpana) i loko o ka mold cylinder e hana ai i ka mold cylinder i hui ʻia.A ua hoʻokumu ʻia ka blank i loko o ka lua i haku ʻia me nā ʻāpana hapa ʻelua.

ʻO ka hui kiʻiʻoniʻoni maʻamau i haku ʻia i ʻelua ʻāpana, ʻo nā ʻāpana luna a me lalo.I mea e hoʻohālikelike ai i ka make o luna a me lalo a pale i ka hoʻololi ʻana o nā forgings, hoʻohana pinepine ʻia nā pou alakaʻi a me nā pine alakaʻi no ka hoʻonohonoho ʻana.Hoʻohana pinepine ʻia ka die clamping e hana i nā forgings non-revolving forgings me nā ʻano paʻakikī, e like me nā lāʻau hoʻohui, nā forging fork, etc.

Ke hoʻohālikelike ʻia me ka forging manuahi, loaʻa i ka tire die forging nā pono penei:

(1) No ka mea, ua hoʻokumu ʻia ka blank i loko o ka lua make, ʻoi aku ka pololei o ka nui o ka forging a maʻalahi ka ʻili.

(2) He kūpono ka hāʻawi ʻana i nā kiko streamline, no laila ke kiʻekiʻe ka maikaʻi.

(3) Hiki i ka hoʻoheheʻe ʻana i nā huila me nā ʻano paʻakikī.Ma muli o ke ʻano o ka forging e hoʻomalu ʻia e ka lua make, ua hana koke ʻia ka blank.A ʻo 1 a 5 mau manawa ke kiʻekiʻe o ka huahana ma mua o ka forging manuahi.

(4) He liʻiliʻi nā poloka i koe, no laila, liʻiliʻi ka haʻawina mīkini.ʻAʻole kēia e hoʻopakele wale i nā mea metala akā e hōʻemi ana i ka machining man-hours.

Nā hemahema:

(1) Pono ka hāmare forging me ka tonage nui;

(2) Hiki ke hana ʻia i nā forging liʻiliʻi;

(3) He haʻahaʻa ke ola lawelawe o ka ʻōpala huila;

(4) He mea maʻamau ka hilinaʻi ʻana i ka manpower e hoʻoneʻe i ka paʻi kaʻa i ka wā o ka hana, no laila ua kiʻekiʻe ka ikaika o ka hana;

(5) Hoʻohana ʻia ʻo Tire die forging no ka hana ʻana i nā pūʻulu liʻiliʻi a me ka liʻiliʻi o ka forgings.

He mea kaulana ʻo Zhengximea hana mīkini forging ma Kina, hāʻawi ʻana i nā ʻano paʻi forging like ʻole, me nā mīkini forging manuahi, nā mīkini forging die,nā mīkini kalai wela, nā mīkini hana anu, a me nā mīkini hoʻoheheʻe mahana, a me nā mea ʻē aʻe.

Ka manawa hoʻouna: Iune-30-2023