1. Free forging

Forging yemahara inoreva nzira yekugadzirisa yekushandisa yakapusa-yechinangwa maturusi kana kushandisa zvakananga simba rekunze kune isina chinhu pakati pepamusoro nepazasi anvils yemidziyo yekuforoma kushatisa isina chinhu kuti uwane mafogi ane inodiwa geometric chimiro uye mukati mhando.

Forging yemahara inonyanya kuburitsa forging mumabatch madiki.Kugadzira midziyo yakaita sesando dzekufombera uye hydraulic presses inoshandiswa kugadzira ma blanks kuti iwane mafogi ane hunyanzvi.Yemahara forging inotora nzira inopisa yekubikira.

Iyo yemahara forging process inosanganisira yekutanga maitiro, yekubatsira maitiro, uye yekupedzisa maitiro.

Nzira huru yekugadzira mahara inogumbura, kudhirowa, kurovera, kukotama, kucheka, kumonyorora, kushandura uye kuforoma, nezvimwewo. Asi matatu anonyanya kushandiswa mukugadzira chaiwo anogumbura, kudhirowa, uye kurova.

Maitiro ekubatsira: pre-deformation process, sekutsikirira shaya, kudzvanya mupendero wesimbi ingot, kucheka bendekete, nezvimwe.

Kupedzisa maitiro: maitiro ekudzikisa kuremara kwepamusoro kwefogi, sekubvisa kusaenzana uye kuumbwa kwenzvimbo yekugadzira.

Advantage:

(1) The forging flexibility yakakura, inogona kuburitsa zvidimbu zvidiki zvisingasviki 100kg.Uye inogonawo kugadzira zvidimbu zvinorema kusvika ku300t.

(2) Zvishandiso zvinoshandiswa zviri nyore-chinangwa-chinangwa maturusi.

(3) Kuumbwa kwemafogi ndiko kukanganisa zvishoma nezvishoma iyo isina chinhu munzvimbo dzakasiyana.Naizvozvo, matani emidziyo yekufogisa inodiwa kuforoma imwe cheteyo idiki pane yekufa forging.

(4) Yakaderera kunyatsojeka zvinodiwa zvemidziyo.

(5) Kutenderera kwekugadzira kupfupi.

Zvakaipa:

(1) Kubudirira kwekugadzira kwakadzikira pane kuya kwekufa kwekugadzira.

(2) Mafogi ane zvimiro zvakapfava, yakaderera dimensional kurongeka, uye nzvimbo dzakakasharara.

(3) Vashandi vane hukuru hwekushanda uye vanoda hunyanzvi hwepamusoro.

(4) Hazvisi nyore kuona mechanization uye otomatiki.

2. Kufa kuhura

Die forging zvinoreva nzira yekugadzira iyo mafogi anowanikwa nekugadzira ma blanks ane mafi pamidziyo yakakosha yekufogisa.Mafukidziro anogadzirwa neiyi nzira akanyatso saizi, madiki mumvumo yekugadzira, yakaoma muchimiro, uye yakakwirira mukubudirira.

Yakarongedzerwa zvinoenderana nemidziyo inoshandiswa: kufa kuforoma pasando, kufa kuforoma pamushini we crank press, kufa uchigadzira pamushini wefodya wekufogisa, kufa uchigadzira pamuchina wekukwenya, nezvimwe.

Zvakanakira:

(1) Kubudirira kwekugadzirwa kwepamusoro.Munguva yekufa kwekugadzira, deformation yesimbi inoitwa mumhango yekufa, saka chimiro chinodiwa chinogona kuwanikwa nekukurumidza.

(2) Mafogi ane zvimiro zvakaoma anogona kugadzirwa.

(3) Inogona kuita kuti kugoverwa kwesimbi kuve kunonzwisisika uye kugadzirisa hupenyu hwebasa rezvikamu.

(4) Saizi yedhivha yekugadzira yakanyatsojeka, iyo yepamusoro mhando iri nani, uye machining mvumo idiki.

(5) Chengetedza zvinhu zvesimbi uye kuderedza basa rekucheka.

(6) Pasi pemamiriro ezvikwata zvakakwana, mutengo wezvikamu unogona kuderedzwa.

Zvakaipa:

(1) Huremu hwemafarogi anoganhurirwa nekukwanisa kwechikafu chekugadzira midziyo, kazhinji iri pasi pe7 kg.

(2) Kutenderera kwekugadzira kwefogi kufa kwakareba uye mutengo wakakwira.

(3) Mutengo wekudyara wemidziyo yekugadzira wakakura kupfuura yefree forging press.

3. Roll forging

Roll forging zvinoreva nzira yekuumba umo mapeya anotenderera-anotenderedza akafa ane chimiro chefani anoshandiswa kukanganisa billet nepurasitiki kuti awane kufogisa kana kufovha billet.

Roll forging deformation yakaoma-dimensional deformation.Zvizhinji zvezvakaremara zvinhu zvinoyerera zvichitevedza kureba kutungamira kuti uwedzere kureba kwebillet, uye chikamu chidiki chechinhu chinoyerera nechemberi kuti chiwedzere hupamhi hwebillet.Munguva yekugadzira roll, iyo muchinjiko-chikamu cheiyo billet midzi inoderera ichienderera.Iyo roll forging process inoshandisa iyo musimboti wekugadzira roll kuti zvishoma nezvishoma igadzirise isina chinhu.

Roll forging inokodzera deformation maitiro senge elonging shafts, rolling slabs, uye kugovera zvinhu nenzira yekureba.Roll forging inogona kushandiswa kugadzira matanda ekubatanidza, twist drill bits, wrenches, spikes yemumugwagwa, mapadza, mapiki uye turbine blades, nezvimwe.

Kuenzaniswa neyakajairwa kufa forging, roll forging ine zvakanakira zveyakapusa dhizaini dhizaini, yakagadzikana kugadzirwa, yakaderera vibration uye ruzha, nyore otomatiki, uye yakakwirira kugadzirwa.

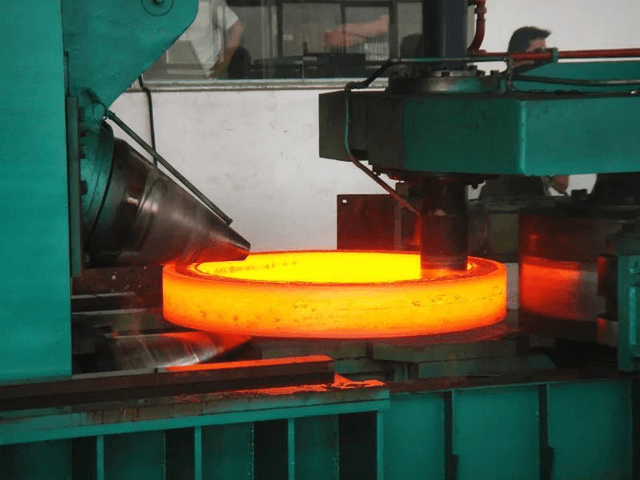

4. Tire kufa kuforoma

Tire die forging inzira yekugadzira iyo inotora nzira yemahara yekufombera kuita isina chinhu, yozoigadzira muforoma yevhiri.Iyo inzira yekugadzira pakati pemahara forging uye kufa forging.Inoshandiswa zvakanyanya mumabhizinesi madiki uye epakati nepakati ane mashoma anofa ekugadzira michina uye mazhinji acho ndeemahara ekuforoma sando.

Kune akawanda mhando dzematayi mold anoshandiswa mukugadzira matai mold, uye anowanzo shandiswa mukugadzira mhando yekudonha, buckle mold, set mold, cushion mold, clamping mold, nezvimwe.

Iyo yakavharwa cylinder die inonyanya kushandiswa kugadzira rotary forgings.Semuyenzaniso, magiya ane maboss kumativi ese ari maviri dzimwe nguva anoshandiswa kugadzira mafogi asingatenderere.Yakavharwa cylinder die forging is flash-free forging.

Kune matai mold forgings ane maumbirwo akaomarara, zvinodikanwa kuwedzera maviri hafu molds (kureva, kuwedzera kupatsanura pamusoro) muhumburumbira mold kuita yakasanganiswa silinda mold.Uye iyo isina chinhu inoumbwa mugomba inoumbwa nehafu molds.

Iyo firimu inoumbwa kazhinji inoumbwa nezvikamu zviviri, kumusoro uye pasi molds.Kuti uenderane nepamusoro uye yepasi inofa uye kudzivirira mafogi kubva pakuchinja, kutungamira mitsara uye mapini ekutungamira anowanzo shandiswa pakuisa.Die clamping inonyanya kushandiswa kugadzira maforogo asingatenderere ane maumbirwo akaomarara, senge matanda ekubatanidza, forogo forging, nezvimwe.

Kuenzaniswa nemahara forging, tire die forging ine zvinotevera zvakanakira:

(1) Sezvo iyo isina chinhu ichiumbwa mugomba rekufa, saizi yefogi yakanyatso kurongeka uye nzvimbo yacho yakati chechetere.

(2) Kugoverwa kwetishu inoyerera inonzwisisika, saka mhando yacho yakakwirira.

(3) Kugadzira mataira kunogona kugadzira mafogi ane maumbirwo akaoma kunzwisisa.Sezvo chimiro chekugadzira chinodzorwa nefa mhango, iyo isina chinhu inoumbwa nekukurumidza.Uye kugadzirwa kwacho kunosvika 1 kusvika ku5 nguva dzakakwirira pane iyo yemahara forging.

(4) Kune mashoma asara mabhuroko, saka machining allowance idiki.Izvi hazvingochengetedze simbi zvinhu chete asiwo zvinoderedza machining man-awa.

Zvakaipa:

(1) Panodiwa nyundo yekuforoma ine tonnage yakakura;

(2) Zvigadzirwa zviduku chete zvinogona kugadzirwa;

(3) Hupenyu hwesevhisi hwechiumbwa chevhiri hwakaderera;

(4) Zvinowanzodikanwa kuvimba nevashandi kuti vafambise mold yevhiri panguva yebasa, saka simba rekushanda rakanyanya kukwirira;

(5) Kugadzira mataira kunoshandiswa kugadzira zvidimbu zvepakati uye zvidiki zvefogi.

Zhengxi anozivikanwa zvikurukugadzira muchina wekugadzira muChina, ichipa marudzi akasiyana-siyana ekudhinda michina, kusanganisira yemahara yekufombera michina, kufa forging michina,inopisa yekuumba michina, inotonhora yekuumba michina, uye inodziya yekugadzira michina, nezvimwewo Kana uine chero zvaunoda, tapota taura nesu.

Nguva yekutumira: Jun-30-2023