1. Ukufoja mahhala

Ukukhohlisa kwamahhala kubhekisela endleleni yokucubungula yokusebenzisa amathuluzi alula enhloso evamile noma ukusebenzisa ngokuqondile amandla angaphandle endaweni engenalutho phakathi kwe-anvils engenhla nengaphansi yemishini yokubumba ukuze kukhubaze okungenalutho ukuze kutholwe ama-forging anomumo wejometri odingekayo kanye nekhwalithi yangaphakathi.

Ukufoja kwamahhala kukhiqiza ama-forging ngamaqoqo amancane.Imishini yokubumba efana nezando zokubumba kanye nomshini wokunyathelisa we-hydraulic isetshenziselwa ukwakha izikhala ukuze kutholwe ama-forging afanelekayo.Ukufoja kwamahhala kusebenzisa indlela yokubumba eshisayo.

Inqubo yamahhala yokwakha ifaka inqubo eyisisekelo, inqubo yokusiza, nenqubo yokuqeda.

Inqubo eyisisekelo yokufoja mahhala iwukucasula, ukudweba, ukubhoboza, ukugoba, ukusika, ukusonta, ukugudluka nokufoja, njll. Kodwa izinqubo ezintathu ezivame ukusetshenziswa kakhulu ekukhiqizeni kwangempela ziyacasula, ukudweba, nokushaya.

Inqubo yokusiza: inqubo yokuguqulwa kwangaphambili, njengokucindezela umhlathi, ukucindezela unqenqema lwensimbi yensimbi, ukusika ihlombe, njll.

Inqubo Yokuqeda: Inqubo yokwehlisa izici zangaphandle zokukholelwa, njengokususa ukungalingani nokwakheka kwendawo evuthayo.

Inzuzo:

(1) Ukuguquguquka kokubumba kukhulu, kungakhiqiza izingcezu ezincane ezingaphansi kuka-100kg.Futhi ingakhiqiza izingcezu ezinzima ezifika ku-300t.

(2) Amathuluzi asetshenziswayo angamathuluzi alula enhloso evamile.

(3) Ukwakhiwa kokwakheka kufanele kudale kancane kancane kungenalutho ezifundeni ezihlukile.Ngakho-ke, i-tonnage yemishini edingayo ukuze kwakhiwe ukubhekelwa okufanayo kuncane kakhulu kunalokho okufa.

(4) Izidingo zokunemba okuphansi kwezisetshenziswa.

(5) Umjikelezo wokukhiqiza mfushane.

Ububi:

(1) Ukusebenza kahle kokukhiqiza kuphansi kakhulu kunaleyo yokufaka ifa.

(2) Ama-Forging anomumo olula, ukunemba kwe-dimensional ephansi, nezindawo ezimaholoholo.

(3) Abasebenzi banomfutho ophakeme womsebenzi futhi badinga amazinga aphezulu ezobuchwepheshe.

(4) Akulula ukubona umshini kanye ne-automation.

2. Ukufa ngokukhohlisa

I-Die forging ibhekisela endleleni yokubumba lapho kutholakala khona ama-forging ngokwenza izikhala ngama-dies emishinini ekhethekile yokubumba.Ama-forging akhiqizwa yile ndlela anembe ngosayizi, amancane emalini yokukhiqiza imishini, ayinkimbinkimbi ngesakhiwo, futhi aphezulu ngokukhiqiza.

Ihlukaniswa ngokwemishini esetshenziswayo: i-die forging esando, i-die forging ku-crank press, i-die forging emshinini wokubumba oyisicaba, i-die forging emshinini wokushayisana, njll.

Izinzuzo:

(1) Ukusebenza kahle kokukhiqizwa okuphezulu.Ngesikhathi sokufa kwazo, ukuguqulwa kwensimbi kwenziwa emgodini ofayo, ngakho-ke ukwakheka okufunayo kungatholwa ngokushesha.

(2) Izimbobo ezinezimo eziyinkimbinkimbi zingakhiwa.

(3) Kungenza ukusatshalaliswa kwensimbi kube lula futhi kuthuthukise impilo yesevisi yezingxenye.

(4) Usayizi we-faging forging unembe kakhulu, ikhwalithi yangaphezulu ingcono, kanye nesibonelelo somshini sincane.

(5) Londoloza izinto zensimbi futhi unciphise umsebenzi wokusika.

(6) Ngaphansi kwesimo samaqoqo anele, izindleko zezingxenye zingancishiswa.

Ububi:

(1) Isisindo sezinsimbi zokubumba zinqunyelwe umthamo wemishini yokubumba eyejwayelekile, ikakhulukazi ngaphansi kuka-7 kg.

(2) Umjikelezo wokukhiqiza wokufa okufile mude futhi izindleko ziphezulu.

(3) Izindleko zokutshala imali zokufa kwemishini zinkulu kunalokhoUkukhishwa kwamahhala kwabezindaba.

3. Roll ukuklaba

I-roll forging isho inqubo yokubumba lapho okubili okufana nefeni okuphendukayo kusetshenziselwa ukuguqula i-billet ngokwepulasitiki ukuze kutholwe i-billet efunwayo yokufoja noma yokufoja.

I-Roll Recuting Deformation ingukuguquguquka okuyinkimbinkimbi kwezintathu.Iningi lezinto ezikhubazekile zigeleza ngobude besiqondiso ukuze kwandiswe ubude be-billet, futhi ingxenye encane yezinto ezibonakalayo igeleza eceleni ukuze ikhulise ububanzi be-billet.Ngesikhathi senqubo yokwakhiwa kwe-roll, indawo ephambanisa nesigaba sempande ye-billet iyehla ngokuqhubekayo.Inqubo yokwakhiwa kwe-Roll Rectise isebenzisa umgomo wokuqalisa kabusha ukuze uguqule kancane kancane.

I-Roll forging ilungele izinqubo zokuguquguquka njengama-shaft anwebekayo, ama-slabs aqengqelekayo, nokusabalalisa izinto ngobude.Ukukhishwa kwe-Roll kungasetshenziselwa ukukhiqiza izinduku zokuxhuma, izingcezu zokudonsa ezisontekile, ama-wrenches, ama-spikes emigwaqo, ama-hoes, amakhethini kanye nama-turbine blade, njll.

Uma kuqhathaniswa ne-die forging evamile, ukubumba ama-roll kunezinzuzo zesakhiwo esilula semishini, ukukhiqizwa okuzinzile, ukudlidliza okuphansi nomsindo, ukuzenzela okulula, nokusebenza kahle kokukhiqiza okuphezulu.

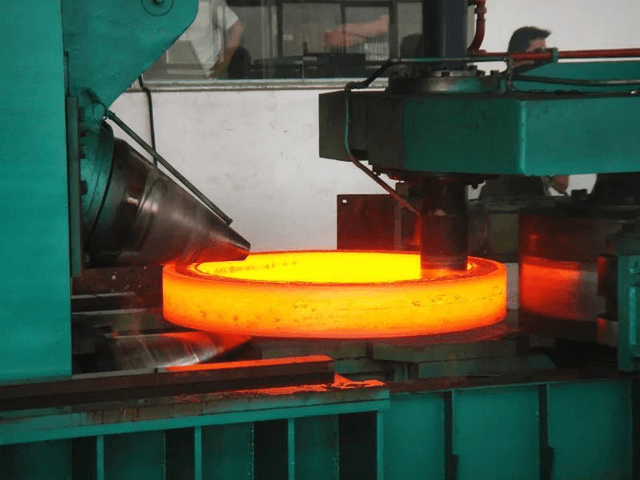

4. ITire Diel

I-Tire die Forging iyindlela yokubumba esebenzisa indlela yamahhala yokwenza into engenalutho, bese iyenze ekubunjweni kwesondo.Kuyindlela evumayo phakathi kokusolwa kwamahhala nokufa.Isetshenziswa kabanzi emabhizinisini amancane naphakathi nendawo anokufa okungatheni kwemishini yokufa futhi iningi lawo liyakha izando.

Kunezinhlobo eziningi zokubumba amathayi ezisetshenziswa ekubumbeni isondo, futhi okuvame ukusetshenziswa ekukhiqizeni uhlobo lwe-drop, isikhunta se-buckle, isikhunta esisethiwe, isikhunta se-cushion, isikhunta sokubopha, njll.

I-cylinder die evaliwe isetshenziswa kakhulu ukwenza ama-rotary forgings.Isibonelo, amagiya anabaphathi emikhawulweni yomibili kwesinye isikhathi asetshenziselwa ukufoja amafogi angajiki.I-cylinder die forging evaliwe ayifogi ngaphandle kwe-flash.

Ukuze uthole ubizo lwethayi elinobukhulu obuyinkimbinkimbi, kuyadingeka ukwengeza isikhunta ezimbili (okungukuthi, engeza indawo yokuhlukanisa) kusilinda isilinda ukwenza isikhunta esihlanganisiwe sokubumba.Futhi okungenalutho kwakhiwa emgodini owakhiwe izibungu ezimbili eziyingxenye.

Ifilimu eliyinhlanganisela livame ukwakhiwa izingxenye ezimbili, isikhunta esingenhla nesiphansi.Ukuze uqondanise amafa angenhla naphansi futhi uvimbele ukubumba ukuthi kungagudluki, izigxobo eziqondisayo nezikhonkwane zomhlahlandlela zivame ukusetshenziselwa ukubeka.I-die clamping isetshenziswa kakhulu ukukhiqiza ama-forging angaguquki anomumo oyinkimbinkimbi, njengezinduku zokuxhuma, izimfoloko, njll.

Uma kuqhathaniswa nokufoja kwamahhala, ukufoja isondo kunezinzuzo ezilandelayo:

(1) Njengoba kungenalutho kwakhiwa emgodini we-die, usayizi wokuvuzayo uqondile futhi ingaphezulu bushelelezi.

(2) Ukusatshalaliswa kwezicubu ezihambisanayo kunengqondo, ngakho-ke ikhwalithi iphakeme.

(3) Ukufoja isondo kungakha ama-forging anezimo eziyinkimbinkimbi uma kuqhathaniswa.Njengoba ukuma kwe-forging kulawulwa yi-cavity ye-die, okungenalutho kwakhiwa ngokushesha.Futhi ukukhiqiza kungu-1 kuye ku-5 amahlandla aphezulu kunalokho okumahhala.

(4) Kunamabhulokhi ambalwa asele, ngakho-ke imali yomshini incane.Lokhu akugcini nje ngokusindisa impahla yensimbi kodwa futhi kunciphisa amahora okusebenza ngomshini.

Ububi:

(1) Kudingeka isando sokubumba esinamathoni amakhulu;

(2) Kungakhiqizwa izimbotshana ezincane kuphela;

(3) Impilo yesevisi yesikhunta samasondo iphansi;

(4) Ngokuvamile kuyadingeka ukuncika kubantu abaningi ukuhambisa isikhunta samathayi ngesikhathi somsebenzi, ngakho-ke amandla abasebenzi aphezulu;

(5) Ukwakhiwa kwethayi kusetshenziselwa ukukhiqiza iziqephu ezimaphakathi nezincane zokubumba.

UZhengxi ungumbungazi oveleleUkwenza umenzi womshini eChina, ukuhlinzeka ngezinhlobo ezahlukene zemishini yokukhanga, kuhlanganise nemishini yokufoja yamahhala, imishini yokufoja,hot forging imishini, imishini yokubumba ebandayo, nemishini yokubumba efudumele, njll. Uma unezidingo, sicela usithinte.

Isikhathi sokuthumela: Jun-30-2023