1. Ukuzenzela mahala

Ukunyanzelwa simahla kubhekisa kwindlela yokusebenzisa izixhobo ezilula zenjongo okanye ukusebenzisa amagunya angaphandle kwibala lemigangatho ephezulu kunye nezixhobo zejometri kunye nomgangatho wangaphakathi.

Ukubunjwa kwasimahla kuvelisa i-forging kwiibhetshi ezincinci.Izixhobo zokwenza ukuba zenza izando zehati kunye noomatshini bokushicilela be-hyddraulic basetyenziselwa ukwenza izinto ezingenanto ukufumana okuzimeleyo.Ukubumba simahla kwamkela indlela eshushu yokubumba.

Inkqubo yokufowuna yasimahla ibandakanya inkqubo esisiseko, inkqubo encedisayo, kunye nenkqubo yokugqiba.

Inkqubo esisiseko yokukhulula ngokukhululekileyo iyaphazamisa, ukudweba, ukubetha, ukugoba, ukusika, ukuguqula, ukuguqula kunye nokukhwabanisa, njl.

Inkqubo yokuncedisa: inkqubo yokuguqulwa kwangaphambili, njengokucinezela umhlathi, ukucinezela umda we-ingot yensimbi, ukusika ihlombe, njl.

Inkqubo yokugqiba: inkqubo yokunciphisa iziphene ezingaphezulu kwe-forgings, ezifana nokususa ukungalingani kunye nokubunjwa kwendawo yokubumba.

I-advanteji:

(1) Ukuqulunqa bhetyebhetye kukhulu, kungavelisa iziqwenga ezincinci ezingaphantsi kwe-100kg.Kwaye inokuvelisa iziqwenga ezinzima ukuya kuthi ga kwi-300t.

(2) Izixhobo ezisetyenzisiweyo zizixhobo ezilula ezilula.

(3) Ukubunjwa kwezinto zokubumba kukuguqula ngokuthe ngcembe indawo engenanto kwimimandla eyahlukeneyo.Ke ngoko, itoni yezixhobo zefomati ezifunekayo ukuba inyanzele ukuba i-gorcy efanayo incinci kakhulu kunoko inyanzelekile.

(4) Iimfuno ezichanekileyo ezisezantsi zezixhobo.

(5) Umjikelo wemveliso umfutshane.

Izinto ezingeloncedo:

(1) Ukusebenza kakuhle kwemveliso kuphantsi kakhulu kuneyo yokufa.

2

(3) Abasebenzi banomsebenzi ophezulu kwaye bafuna amanqanaba aphezulu obugcisa.

(4) Akukho lula ukuqonda oomatshini kunye ne-automation.

2. Ukufa ngokukhohlisa

Ukufa ukrokrela kubhekisa kwindlela yokukhangela apho ujongiswayo afunyanwa ngokwenza amathuba ngokufa kwizixhobo ezikhethekileyo zokufa.Ukuxelwa okuvezwe ngale ndlela kukuchaneka ngobukhulu, ezincinci kwizibonelelo zomatshini, kunzima kwisakhiwo, kwaye ziphezulu kwimveliso.

Ihlelwe ngokwezixhobo ezisetyenzisiweyo: Dila kwi-hammer, ifa kwi-crank messing, ifa kwi-Fied kumatshini wokuthambisa, yifa kuMatshini weFlatch, njl.

Izinto eziluncedo:

(1) Ukusebenza okuphezulu kwemveliso.Ngexesha lokufa, ukungcungcuthekiswa kwesinyithi kwenziwa kwi-cevity yokufa, ngoko ke kwafunyanwa imilo oyifunayo ngokukhawuleza.

(2) Izakhelo ezinemilo entsonkothileyo zinokubunjwa.

(3) Inokwenza ukuba ukuhanjiswa kwentsimbi kube nengqiqo ngakumbi kwaye kuphuculwe ubomi benkonzo yamacandelo.

(4) Ubungakanani be-faging forging buchaneke ngakumbi, umgangatho womphezulu ungcono, kwaye isibonelelo somatshini sincinci.

(5) Gcina izinto zetsimbi kwaye unciphise umsebenzi wokusika.

(6) Ngaphantsi kwemeko yeebhetshi ezaneleyo, iindleko zeengxenye zinokuncitshiswa.

Izinto ezingeloncedo:

(1) Ubunzima bezixhobo zokubumba iifayibhile bukhawulelwe ngumthamo wesixhobo sobumbi sokufa ngokubanzi, ubukhulu becala ngaphantsi kwe-7 kg.

.

(3) Ixabiso lokutyalomali lokufa kwezixhobo zokufakwa likhulu kunelofree forging press.

3. Qengqeleka

Ukuqulunqa umqulu kubhekiselele kwinkqubo yokubumba apho ipere ezijikezayo ezinemilo yefeni zisetyenziselwa ukuguqula ibhilethi ngokweplastiki ukuze kufumaneke ibhilethi efunwayo yokufunxa okanye yokufoja.

Roll forging deformation yinto entsonkothileyo ene-dimensional deformation.Uninzi lwezinto eziphathekayo ezihamba ngaphaya kwendlela ubude ukonyusa ubude beBillet, kunye nenxalenye encinci yezinto ezihamba-hamba zihamba kamva ukwandisa ububanzi beBillet.Ngexesha lenkqubo yokunyanzelwa, indawo enqamlezileyo yecandelo le-billet incipha ngokuqhubekayo.Inkqubo yeforati isebenzisa umgaqo-nkqubo wokuqulunqa ukwenziwa ngokuthe ngcembe ukuba ichaphazele.

I-roll forging ifanelekile kwiinkqubo zokuguqulwa ezifana ne-shafts emide, ii-slabs eziqengqelekayo, kunye nokusabalalisa izinto ezihambelana nobude.I-Roll forging ingasetyenziselwa ukuvelisa ii-rods ezidibanisayo, i-twist drill bits, i-wrenches, i-spikes yendlela, ii-hoes, iipeki kunye nee-turbine blades, njl.

Xa kuthelekiswa nokukrwada kwesiqhelo, ukrola kuneengenelo zolwakhiwo lwezixhobo ezilula, ukuvelisa ezizinzileyo, ukuveliswa okuphantsi, ingxolo, ukulungelelaniswa kwempumelelo kwemveliso.

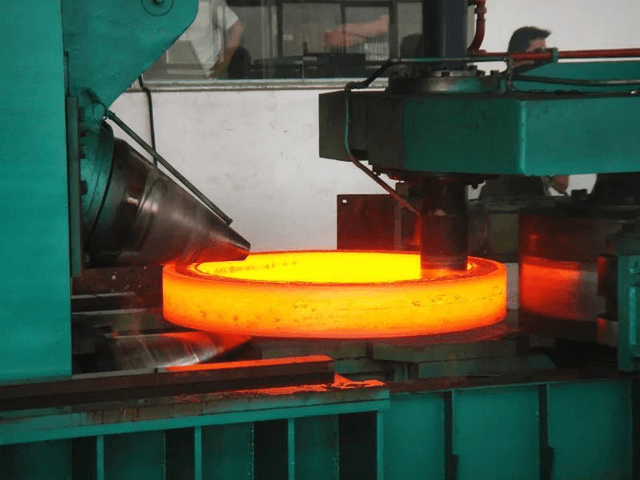

4. ITire iyafa izenzela

ITire die forging yindlela yokubumba eyamkela indlela yokufoja simahla ukwenza indawo engenanto, ize iyifake kwisingundo setayara.Yindlela yokubumba phakathi kokwenza simahla kunye ne-die forging.Isetyenziswa kakhulu kumashishini amancinci naphakathi anezixhobo zokubumba ezifayo ezincinci kwaye uninzi lwazo ziihamile zokuzenzela simahla.

Zininzi iindidi zezibumba ze-tire ezisetyenziswayo kwi-tire yokutsala, kwaye ezisetyenziswayo ezisetyenziswayo kwimveliso ziluhlobo, i-buckle mold, iseti ye-Buck, i-Clample.

I-cylinder die evaliweyo isetyenziswa kakhulu ekwenzeni i-rotary forgings.Umzekelo, iigiya ezinabaphathi kuzo zozibini iziphelo ngamanye amaxesha zisetyenziselwa ukwenza iifogi ezingajikiyo.I-cylinder die forging evaliweyo kukufoja ngaphandle kwe-flash.

Ukubumba isondo lokubumba kunye neemilo eziyinkimbinkimbi, kuyimfuneko ukongeza iimbumba ezimbini zesiqingatha (oko kukuthi, ukongeza indawo yokuhlukana) kwi-cylinder mold ukwenza i-cylinder mold edibeneyo.Kwaye i-blank yenziwe kwi-cavity eyakhiwe ngama-molds amabini.

Ifilimu edibeneyo idla ngokuqulunqwa ngamacandelo amabini, i-molds ephezulu nesezantsi.Ukwenzela ukutshatisa i-OPT kunye nesezantsi i-DEE DEE kwaye inqande ukuxolela okuvela ekutshintsheni, izithuba zesikhokelo kunye nezikhonkwane zezikhokelo zihlala zisetyenziselwa ukubeka.Ukudalwa kwe-chipping kusetyenziswa kakhulu ukuvelisa uxolelo olungaguqukiyo oluneemilo ezintsonkothileyo, njengokudibanisa iintonga, ukuxolelaniswa kweentonga, ukuxolelanisa, njl.

Xa kuthelekiswa nokufoja simahla, ukufoja ivili kunezi nzuzo zilandelayo:

(1) Ekubeni isithuba esingenanto senziwa kumngxunya wokufa, ubungakanani bokubumba buchanekile ngokwentelekiso kwaye umphezulu ugudile.

(2) Ukuhanjiswa kwezicubu ezijikelezayo kunengqiqo, ngoko umgangatho uphezulu.

(3) Ukubunjwa kweTire kunokuvelisa izinto ezintsonkothileyo.Ekubeni imilo ye-forging ilawulwa ngumgodi wokufa, i-blank blank ngokukhawuleza.Kwaye imveliso i-1 ukuya ku-5 amaxesha aphezulu kunoko lokufoja simahla.

(4) Kukho iibhloko ezimbalwa eziseleyo, ngoko ke isibonelelo somatshini sincinci.Oku akugcini nje ukugcina izinto zetsimbi kodwa kunciphisa iiyure zomntu osebenza ngomatshini.

Izinto ezingeloncedo:

(1) Ihamile yobumba enetoni enkulu iyafuneka;

(2) Kuphela nje okuxolelekileyo okuxolelwayo;

(3) Ubomi benkonzo ye-cire bubuld buphantsi;

(4) Ngokuqhelekileyo kuyimfuneko ukuthembela kubasebenzi ukuhambisa ukungunda kwetayara ngexesha lomsebenzi, ngoko ke amandla okusebenza aphakamileyo kakhulu;

5

UZhengxi ngumntu owaziwayoumenzi womatshini wokubumba eTshayina, ukubonelela ngeentlobo ezahlukeneyo zoomatshini bokubumba, kubandakanywa oomatshini bokubumba basimahla, oomatshini bokubumba abafayo,oomatshini bokubumba abashushu, oomatshini bokubumba obubandayo, kunye nokufudumala koomatshini bokubumba, njl. Ukuba unayo nayiphi na imfuno, nceda uqhagamshelane nathi.

Ixesha lokuposa: Jun-30-2023